GE Power Management

745 Transformer Management Relay

10-25

10 COMMISSIONING

10.6 PROTECTION SCHEMES

10

3.

When the element operates, check that the TRIP, PICKUP and PHASE LEDs are on and the following

message is displayed:

4.

Reduce the current until the element resets. The reset level should be 97% of the operate level. When the

element resets, the TRIP and message indicators should remain on if the TARGET was selected as

latched. Otherwise only the TRIP indicator remains on.

5.

Reset indicators and clear messages.

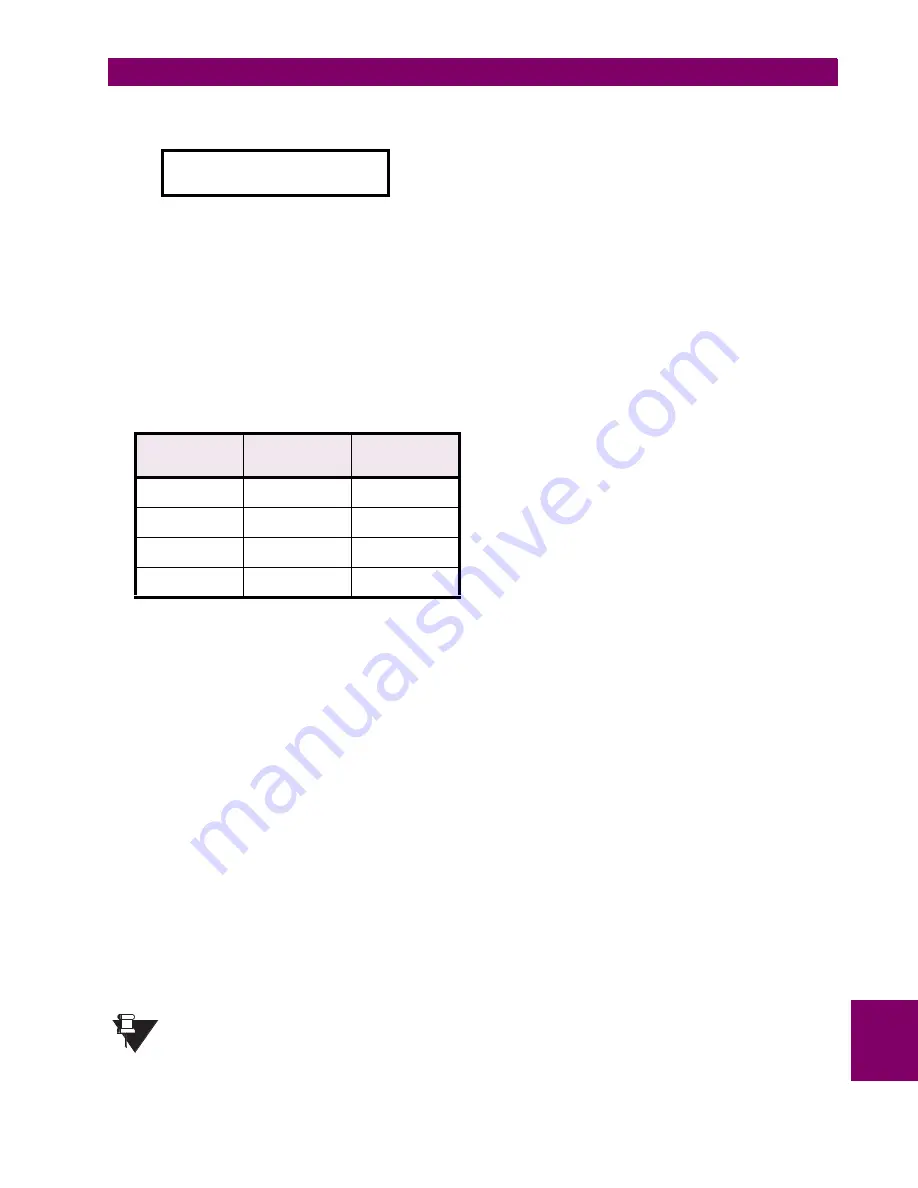

c) OPERATING TIME

Using a table like the one shown below, select 3 or 4 values of current multiples at which timing is to be mea-

sured. Enter the expected operating times from the timing curve applied in the settings. Using the setup in Fig-

ure 10–9: GENERAL TEST SETUP on page 10–21 and the Interval Timer enabled, set the current level to the

desired value and apply suddenly by closing the double-pole switch. Record the operate time and compare to

the expected value. Repeat for all desired values of current.

d) RESET TIME

A precise measurement of the reset time requires a relay test set capable of dynamic operation, with three

sequenced stages, each with programmable current levels and time duration, and flexible external contact trig-

gering. To perform such a test, contact GE Power Management for detailed test instructions.

A simple verification of the reset mode selected under:

SETPOINTS/S4 ELEMENTS/NEUTRAL OC/W1 NTRL TIME OC/W1 NEUTRAL TIME OC RESET

is obtained using the setup shown in Figure 10–9: GENERAL TEST SETUP on page 10–21. The test consists

of repetitive operating time measurements in quick succession. If the reset is set for

INSTANTANEOUS

, the oper-

ating time is always equal to the nominal time derived from the selected curve. If the reset is set as

LINEAR

, the

operating time varies as a function of the time between successive applications of current. The variations in

operating time are easier to detect if this test is performed at current multiples of 2 to 3 times the pickup level.

e) WINDING #2 OR WINDING #3 ELEMENTS

Since the Winding 2 and 3 elements can be set with completely different parameters than the Winding 1 ele-

ments, it is necessary to repeat the full set of tests described above for each winding. To test Winding 2 ele-

ments, disable all protection elements except for

W2 NEUTRAL TIME OVERCURRENT

. Connect the current signal to

X = H4 and Y = G4 and repeat tests in this section. To test Winding 3 elements, disable all protection elements

except for

W3 NEUTRAL TIME OVERCURRENT

. Connect the current signal to X = H7 and Y = G7 and repeat the

tests in this section.

The blocking from logic input, if enabled, can be tested as described in earlier tests for other

elements.

yy

LATCHED (OPERATED)

yy

W1 Ntrl Time OC

CURRENT

MULTIPLE

NOMINAL

TIME

MEASURED

TIME

1.5

3

5

NOTE

Содержание 745 TRANSFORMER MANAGEMENT RELAY

Страница 30: ...2 8 745 Transformer Management Relay GE Power Management 2 3 SECURITY 2 GETTING STARTED 2 ...

Страница 150: ...5 100 745 Transformer Management Relay GE Power Management 5 10 INVERSE VOLTS PER HERTZ CURVES 5 SETPOINTS 5 ...

Страница 210: ...7 36 745 Transformer Management Relay GE Power Management 7 2 BLOCK DIAGRAMS 7 SCHEME LOGIC 7 ...

Страница 322: ...9 12 745 Transformer Management Relay GE Power Management 9 3 USING 745PC 9 745 PC SOFTWARE 9 ...

Страница 392: ...11 24 745 Transformer Management Relay GE Power Management 11 1 COMMISSIONING SUMMARY 11 SETPOINT TABLES 11 ...

Страница 396: ...A 4 745 Transformer Management Relay GE Power Management A 1 FIGURES AND TABLES APPENDIXA A ...

Страница 398: ...B 2 745 Transformer Management Relay GE Power Management B 1 EU DECLARATION OF CONFORMITY APPENDIXB B ...

Страница 400: ...C 2 745 Transformer Management Relay GE Power Management C 1 WARRANTY INFORMATION APPENDIXC C ...

Страница 406: ...vi 745 Transformer Management Relay GE Power Management ...

Страница 407: ...GE Power Management 745 Transformer Management Relay NOTES ...