CLUTCHES AND TRANSMISSIONS 7-5

NOTE:

Use 5/8" thick board in place of floor

mat to give a positive stop.

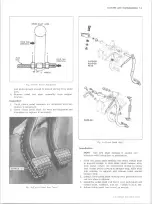

All three readings should be within .010” and

within total lift readings. If more than .010"

check retracting springs per step 2. If trouble

still exists, loosen clutch-to-flywheel mounting

bolt at position of lowest reading (leave other

bolts tight), pry cover, away from flywheel, and

insert feeler gauge (fig. 7) to determine thick

ness of shim required to bring reading within

.

010

".

Total lift readings should be as follows:

L-6 250

.065 to .075

HD 11"

.065 to .085

Make sure proper pedal lash adjustment is made be

fore checking.

NOTE:

Excessively high readings indicate that

the diaphragm spring is being over stressed

which may eventually cause loss of load and

result in slippage.

If above measures fail to correct the trouble, check

driven disc with clutch pedal depressed (it should spin

freely with transmission in neutral). If it does not,

trouble may be:

1. Misalignment between pilot bushing in crankshaft and

clutch housing.

2. Faulty clutch pilot bushing.

3. Faulty driven disc.

SERVICE OPERATIONS

CLUTCH ASSEMBLY

Removal From Vehicle

1. Remove transmission as outlined in "Transmission

Section.”

2. Disconnect slave cylinder from clutch fork.

3. Remove clutch throwout bearing from the fork.

4. Remove clutch fork by pressing it away from its ball

mounting with a screwdriver, until the fork snaps

loose from the ball or remove ball stud from rear of

clutch housing.

NOTE:

The retainer may be removed from the

fork by prying out with a small screwdriver.

5. Install Tool J-5824 or a used clutch drive gear

to support the clutch assembly during removal.

6. Loosen the clutch attaching bolts one turn at a time

to prevent distortion of clutch cover until dia

phragm spring is released.

7. Remove clutch pilot tool and remove clutch assembly

from vehicle.

Installation to Vehicle

1. Install the pressure plate in the cover assembly lin

ing up the notch mark on pressure plate with notch

mark on flange of cover.

2. Install pressure plate retracting springs and drive

strap to pressure plate bolts and lockwashers and

tighten to 11 ft. lbs. torque. The clutch is now ready

to be installed.

3. Hand crank the engine until

“ X”

mark on flywheel is

at the bottom.

4. Install clutch disc, pressure plate and cover assem

bly and support them with Tool J-5824 or a used

clutch drive gear.

5. Turn clutch assembly until " X ” mark on clutch

cover flange lines up with “ X” mark on flywheel.

6. Install attaching bolts and tighten each one a turn at a

time to prevent distorting the cover as the spring

pressure is taken up.

7. Remove clutch pilot Tool.

8. Pack clutch fork ball seat with a small amount of

high melting point grease and install a new retainer

in the groove of the clutch fork if the old retainer is

worn or damaged.

NOTE:

Install retainer with high side up, away

from bottom of the ball socket and with open end

of retainer on the horizontal.

CAUTION:

Be careful not to use too much

lubricant.

9. Replace clutch fork ball if removed from the clutch

housing and snap clutch fork onto the ball.

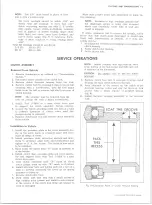

10. Pack lubricant in the recess on the inside of the

throwout bearing collar and coat the throwout fork

groove with a small amount of graphite grease

(fig. 8).

11. Install throwout bearing assembly to the throwout

fork.

Fig. 8— Lubrication Points on C lu tch Throwout Rearing

COAT THIS GROOVE

PACK

THIS

RECESS

10-30 CHEVROLET TRUCK SERVICE MANUAL

Содержание 10 1971 Series

Страница 1: ......

Страница 96: ......

Страница 100: ...10 30 CHEVROLET TRUCK SERVICE MANUAL Fig 4 10 30 Series Truck Frame FRAME 2 4 ...

Страница 120: ......

Страница 203: ...ENGINE 6 25 Fig 22L Engine Mounts 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Страница 215: ...ENGINE 6 37 REAR M O U NT Fig 21V Engine Mounts 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Страница 218: ......

Страница 249: ......

Страница 250: ...EMISSION CONTROL SYSTEMS 6T 4 Fig 3 Combination Emission Control System Routing V8 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Страница 324: ......

Страница 339: ...FUEL TANK AND EXHAUST SYSTEMS 8 15 SPECIAL TOOLS Fig 22 Special Tools 1 J 23346 Fuel Tank Gauge Remover and Installer ...

Страница 340: ......

Страница 365: ...10 30 CHEVROLET TRUCK SERVICE MANUAL Fig 43 Power Steering Pump M ounting STEERING 9 25 ...

Страница 368: ......

Страница 386: ......

Страница 390: ...ELECTRICAL BODY AND CHASSIS 12 4 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Страница 391: ......

Страница 392: ...ELECTRICAL BODY AND CHASSIS 12 6 Fig 5 Rear Lighting Composite 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Страница 409: ...ELECTRICAL BODY AND CHASSIS 12 23 Fig 27 Engine Compartment CA30 02 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Страница 410: ...ELECTRICAL BODY AND CHASSIS 12 24 18DK GRN 19 Fig 28 Instrument Panel CA30 02 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Страница 411: ...ELECTRICAL BODY AND CHASSIS 12 25 Fig 29 Instrument Panel CA30 02 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Страница 412: ...ELECTRICAL BODY AND CHASSIS 12 26 fh Ar r kk 4 Fig 30 Engine Compartment C A K A 10 20 CA30 03 z _ ...

Страница 416: ...ELECTRICAL BODY AND CHASSIS 12 30 Fig 34 Engine Compartment CA KA10 20 CA30 04 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Страница 420: ...ELECTRICAL BODY AND CHASSIS 12 34 Fig 38 Engine Compartment C A K A 1 0 20 06 16 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Страница 422: ...ELECTRICAL BODY AND CHASSIS 12 36 Fig 40 Instrument Panel C A K A 10 20 06 16 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Страница 423: ...ELECTRICAL BODY AND CHASSIS 12 37 Fig 41 R ear Lamps C A K A 1 0 20 06 16 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Страница 424: ...ELECTRICAL BODY AND CHASSIS 12 38 Fig 42 Engine Compartment CA KA10 20 CAl30 14 34 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Страница 426: ...ELECTRICAL BODY AND CHASSIS 12 40 Fig 44 Instrument Panel CA KA10 20 CA30 14 34 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Страница 428: ......

Страница 432: ......

Страница 449: ...SPECIFICATIONS 9 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Страница 463: ......

Страница 464: ......

Страница 465: ......

Страница 466: ......