HEATER AND AIR CONDITIONING 1A-19

• Check the switch adjusting screw for stripped or

otherwise damaged threads,,

Adjusting Switch

If, after the above checks, the switch seems to be op

erating properly, adjust for proper setting if necessary,

as follows:

1. Vehicle must be set up as described in "Perform

ance Test."

2. The suction side of the system, read on the low

pressure gauge, should pull down to the pressure

shown in the chart in "Performance Data" under the

ambient temperature at the time the switch is being

set.

3. Roof-Mounted System - Remove the rear duct screws

and then remove the duct from its side retaining

flanges.

It is not necessary to remove the duct

from its rear retaining flange or disconnect the rear

drain tubes.

GM Chevrolet System - Lower the entire unit from

its dash mounting, remove the duct assembly from

the blower-evaporator unit and then remove the duct

rear cover.

4. Disconnect the switch wiring harness, remove the

switch attaching screws and remove the switch.

NOTE:

On GM Chevrolet Units, the knob must

be pulled off the switch shaft before the switch

can be removed.

5. Remove the switch non-metal end plate to gain ac

cess to the switch adjusting screw.

6. If the outlet temperature was less than the pre

scribed temperature at the end of each cooling cycle,

turn the adjusting screw a partial turn counter

clockwise (fig. 28). If the outlet temperature was

more than prescribed temperature, turn the adjusting

screw clockwise.

NOTE:

One turn of the adjusting screw will

change the outlet temperature approximately 4

degrees.

7. Reinstall switch end plate and install switch. Rein

stall ducts removed in Step 3 above. Be sure that

the air sensing capillary has been replaced properly,

if removed during disassembly.

8. Check system performance. If further adjustment

is needed, repeat Steps 3 through 7 until the pre

scribed pressure is reached.

CAUTION:

Do not attempt to run a Perform

ance Check with the system disassembled since

inaccurate readings would be the result. AL

WAYS reinstall the duct work before running a

performance check.

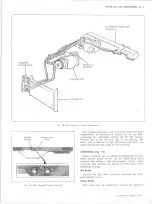

EXPAN SIO N VALVE (Fig. 29)

A malfunction of the -expansion valve will be caused by

one of the following conditions; valve stuck open, valve

stuck closed, broken power element, a restricted screen

or an improperly located or installed power element bulb.

The first three conditions require valve replacement.

The last two may be corrected by replacing the valve inlet

screen and by properly installing the power element bulb.

Attachment of the expansion valve bulb to the evaporator

outlet pipe is very critical. The bulb must be attached

tightly to the pipe and must make good contact with the

pipe along the entire length of the bulb. A loose bulb will

result in high POA pressures and poor cooling. On

bulbs located outside the evaporator case, insulation must

be properly installed.

Indications of expansion valve trouble provided by the

Performance Test are as follows:

VALVE STUCK OPEN

Noisy Compressor.

No Cooling - Freeze Up.

VALVE STUCK CLOSED, P L U G G E D SCREEN OR

BROKEN POWER ELEMENT

Very Low Suction Pressure.

No Cooling.

EXTERNAL

EQUALIZER

LINE

OUTLET

Fig. 2 8 — Thermostatic Switch Adjustment

Fig. 2 9 — Expansion Valve

10-30 CHEVROLET TRUCK SERVICE MANUAL

Содержание 10 1971 Series

Страница 1: ......

Страница 96: ......

Страница 100: ...10 30 CHEVROLET TRUCK SERVICE MANUAL Fig 4 10 30 Series Truck Frame FRAME 2 4 ...

Страница 120: ......

Страница 203: ...ENGINE 6 25 Fig 22L Engine Mounts 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Страница 215: ...ENGINE 6 37 REAR M O U NT Fig 21V Engine Mounts 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Страница 218: ......

Страница 249: ......

Страница 250: ...EMISSION CONTROL SYSTEMS 6T 4 Fig 3 Combination Emission Control System Routing V8 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Страница 324: ......

Страница 339: ...FUEL TANK AND EXHAUST SYSTEMS 8 15 SPECIAL TOOLS Fig 22 Special Tools 1 J 23346 Fuel Tank Gauge Remover and Installer ...

Страница 340: ......

Страница 365: ...10 30 CHEVROLET TRUCK SERVICE MANUAL Fig 43 Power Steering Pump M ounting STEERING 9 25 ...

Страница 368: ......

Страница 386: ......

Страница 390: ...ELECTRICAL BODY AND CHASSIS 12 4 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Страница 391: ......

Страница 392: ...ELECTRICAL BODY AND CHASSIS 12 6 Fig 5 Rear Lighting Composite 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Страница 409: ...ELECTRICAL BODY AND CHASSIS 12 23 Fig 27 Engine Compartment CA30 02 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Страница 410: ...ELECTRICAL BODY AND CHASSIS 12 24 18DK GRN 19 Fig 28 Instrument Panel CA30 02 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Страница 411: ...ELECTRICAL BODY AND CHASSIS 12 25 Fig 29 Instrument Panel CA30 02 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Страница 412: ...ELECTRICAL BODY AND CHASSIS 12 26 fh Ar r kk 4 Fig 30 Engine Compartment C A K A 10 20 CA30 03 z _ ...

Страница 416: ...ELECTRICAL BODY AND CHASSIS 12 30 Fig 34 Engine Compartment CA KA10 20 CA30 04 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Страница 420: ...ELECTRICAL BODY AND CHASSIS 12 34 Fig 38 Engine Compartment C A K A 1 0 20 06 16 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Страница 422: ...ELECTRICAL BODY AND CHASSIS 12 36 Fig 40 Instrument Panel C A K A 10 20 06 16 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Страница 423: ...ELECTRICAL BODY AND CHASSIS 12 37 Fig 41 R ear Lamps C A K A 1 0 20 06 16 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Страница 424: ...ELECTRICAL BODY AND CHASSIS 12 38 Fig 42 Engine Compartment CA KA10 20 CAl30 14 34 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Страница 426: ...ELECTRICAL BODY AND CHASSIS 12 40 Fig 44 Instrument Panel CA KA10 20 CA30 14 34 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Страница 428: ......

Страница 432: ......

Страница 449: ...SPECIFICATIONS 9 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Страница 463: ......

Страница 464: ......

Страница 465: ......

Страница 466: ......