ENGINE-ELECTRICAL 6Y-19

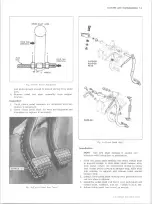

Fig. 9 i—L—6 Distributor Exploded View

1., Breaker Plate Attaching

10. Contact Point Attaching

Screws

Screw

2.

Condenser Attaching Screws 11. Contact Point Assembly

3.

Condenser

12. Weight Cover Attaching

4.

Breaker Plate Assembly

Screws

4o.

Cam Lubricator

13.

Weight Cover

5. Vacuum Control Assembly

14.

Weight Springs

6. Vacuum Control

15. Advance Weights

Attaching Screws

16.

Cam Assembly

7.

Housing

17. M ain Shaft Assembly

8.

Cap

18. Roll Pin

9.

Rotor

19.

Drive Gear

3.

Scribe a realignment mark on the distrbutor bowl

and engine in line with the rotor segment.

4. Disconnect external connections (vacuum line, drive

cables, etc.) remove the distributor hold-down bolt

and clamp, remove the distributor from the engine.

Note position of vacuum advance mechanism relative

to the engine.

CAUTION:

Avoid rotating the engine with the

distributor removed as the ignition timing will

be upset.

Disassembly

It is advisable to place the distributor in a distributor

testing machine or synchroscope prior to disassembly.

When mounting distributors for tests, first secure the

gear in the test drive mechanism, then push the distribu

tor housing downward toward the gear to take up any end

play between the gear and the housing.

NOTE:

When testing distributors that have their

lower shaft support bushing located in the engine

block (6 cylinder engines) a special adapter

should be used to insure the shaft will run true

in its housing.

Test the distributor for variation of spark, correct

centrifugal and vacuum advance and condition of contacts.

This test will give valuable information on distributor

condition and indicate parts replacement which may be

necessary. Check the area on the breaker plate just

beneath the contact points. A smudgy line indicates that

oil or crankcase vapors have been present between the

points.

Six Cylinder Engines

Refer to Figure 9i.

1. Remove the rotor and dust shield.

2. Remove the vacuum control assembly retaining

screws, detach the unit from the distributor housing.

3. Disconnect the primary and condenser leads from

the contact point quick disconnect terminal, remove

the contact point set attaching screw, condenser

attaching screw. Remove the point set and condenser

from the breaker plate.

4. Remove the breaker plate attaching screws, remove

the breaker plate from the distributor housing (fig.

9i).

NOTE:

Do not disassembly breaker plate any

further.

5. Remove the roll pin retaining the driven gear to the

mainshaft, slide the gear from the shaft.

6. Slide the cam and mainshaft from the distributor

housing.

7. Remove the weight cover and stop plate screws, re

move the cover, weight springs, weights and slide

cam assembly from the mainshaft.

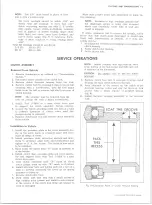

V-8 Engines

Refer to Figure lOi.

1. Remove the rotor.

2. Remove both weight springs and advance weights.

3. Remove roll pin retaining driven gear to the distri

butor shaft, slide the gear and spacers from the

shaft. On heavy duty models remove shock mounting

unit.

4. Before sliding the distributor shaft from the housing,

check for and remove any burrs on the shaft. This

will prevent damage to the seals and bushing still

positioned in the housing.

5. Slide the distributor mainshaft and cam-weight base

assembly from the housing.

10-30 CHEVROLET TRUCK SERVICE MANUAL

Содержание 10 1971 Series

Страница 1: ......

Страница 96: ......

Страница 100: ...10 30 CHEVROLET TRUCK SERVICE MANUAL Fig 4 10 30 Series Truck Frame FRAME 2 4 ...

Страница 120: ......

Страница 203: ...ENGINE 6 25 Fig 22L Engine Mounts 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Страница 215: ...ENGINE 6 37 REAR M O U NT Fig 21V Engine Mounts 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Страница 218: ......

Страница 249: ......

Страница 250: ...EMISSION CONTROL SYSTEMS 6T 4 Fig 3 Combination Emission Control System Routing V8 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Страница 324: ......

Страница 339: ...FUEL TANK AND EXHAUST SYSTEMS 8 15 SPECIAL TOOLS Fig 22 Special Tools 1 J 23346 Fuel Tank Gauge Remover and Installer ...

Страница 340: ......

Страница 365: ...10 30 CHEVROLET TRUCK SERVICE MANUAL Fig 43 Power Steering Pump M ounting STEERING 9 25 ...

Страница 368: ......

Страница 386: ......

Страница 390: ...ELECTRICAL BODY AND CHASSIS 12 4 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Страница 391: ......

Страница 392: ...ELECTRICAL BODY AND CHASSIS 12 6 Fig 5 Rear Lighting Composite 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Страница 409: ...ELECTRICAL BODY AND CHASSIS 12 23 Fig 27 Engine Compartment CA30 02 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Страница 410: ...ELECTRICAL BODY AND CHASSIS 12 24 18DK GRN 19 Fig 28 Instrument Panel CA30 02 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Страница 411: ...ELECTRICAL BODY AND CHASSIS 12 25 Fig 29 Instrument Panel CA30 02 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Страница 412: ...ELECTRICAL BODY AND CHASSIS 12 26 fh Ar r kk 4 Fig 30 Engine Compartment C A K A 10 20 CA30 03 z _ ...

Страница 416: ...ELECTRICAL BODY AND CHASSIS 12 30 Fig 34 Engine Compartment CA KA10 20 CA30 04 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Страница 420: ...ELECTRICAL BODY AND CHASSIS 12 34 Fig 38 Engine Compartment C A K A 1 0 20 06 16 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Страница 422: ...ELECTRICAL BODY AND CHASSIS 12 36 Fig 40 Instrument Panel C A K A 10 20 06 16 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Страница 423: ...ELECTRICAL BODY AND CHASSIS 12 37 Fig 41 R ear Lamps C A K A 1 0 20 06 16 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Страница 424: ...ELECTRICAL BODY AND CHASSIS 12 38 Fig 42 Engine Compartment CA KA10 20 CAl30 14 34 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Страница 426: ...ELECTRICAL BODY AND CHASSIS 12 40 Fig 44 Instrument Panel CA KA10 20 CA30 14 34 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Страница 428: ......

Страница 432: ......

Страница 449: ...SPECIFICATIONS 9 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Страница 463: ......

Страница 464: ......

Страница 465: ......

Страница 466: ......