CLUTCHES AND TRANSMISSIONS 7-14

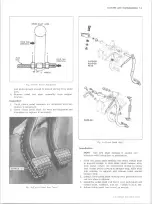

Fig. 1P G — Adjusting Low Band Using J-21848

PERIODIC LOW BAN D ADJUSTMENT (Fig. IP G )

Low band adjustment should be periodically performed

at first transmission fluid change, or sooner, as nec

essary if operating performance indicates low band

slippage.

1. Raise vehicle and place selector lever in neutral.

2. Remove protective cap from transmission adjusting

screw.

3. On some models: To gain clearance between under

body and transmission, it may be necessary to re

move rear mound bolts from crossmember, and

move transmission slightly toward passenger side of

vehicle.

4. Loosen adjusting screw locknut 1/4 turn and hold in

this position with wrench.

5. Using Special Tool J-21848 adjust band to 70 in. lbs.

and back off four (4) complete turns for a band which

has been in operation for 6,000 miles or more, or

three (3) turns for one in use less than 6,000 miles.

CAUTION:

Be^ sure to hold the adjusting screw

locknut at 1/4 turn loose with a wrench during

the adjusting procedure.

6. Tighten the adjusting screw locknut to specified

torque.

CAUTION:

The amount of back-off is not an

approximate figure, it must be exact.

M A N U A L SHIFT LINKAGE CHECK & ADJUST

1. The shift tube and lever assembly must be free in the

mast jacket. See Section 9 for alignment of steering

column assembly if necessary.

2. To check for proper shift linkage adjustment, lift the

transmission selector lever towards the steering

wheel. Allow the selector lever to be positioned in

drive (D) by the transmission detent.

NOTE:

Do not use the indicator pointer as a

reference to position the selector lever. When

performing linkage adjustment, pointer is ad

justed last.

3. Release the selector lever. The lever should be in

hibited from engaging low range unless the lever is

lifted.

4. Lift the selector lever towards the steering wheel,

and allow the lever to be positioned in neutral (N) by

the transmission detent.

5. Release the selector lever. The lever should now be

inhibited from engaging reverse range unless the

lever is lifted.

6. A properly adjusted linkage will prevent the selector

lever from moving beyond both the neutral detent,

and the drive detent unless the lever is lifted to pass

over the mechanical stop in the steering column.

7. In the event that an adjustment is required, place the

selector lever in drive (D) position as determined by

the transmission detent. See Steps 2 and 3.

8. Loosen the adjustment swivel at the mast jacket

lever, and rotate the transmission lever so that it

contacts the drive stop in the steering column.

9. Tighten the swivel and recheck the adjustment. See

Steps 2 and 6.

10. Readjust indicator needle if necessary to agree with

the transmission detent positions. See Section 9.

11. Readjust neutral safety switch if necessary to pro

vide the correct relationship to the transmission

detent positions. See Section 12.

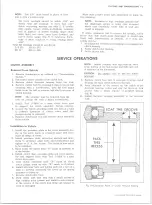

Fig. 2 P G — Powerglide Control Rod Linkage

10-30 CHEVROLET TRUCK SERVICE MANUAL

Содержание 10 1971 Series

Страница 1: ......

Страница 96: ......

Страница 100: ...10 30 CHEVROLET TRUCK SERVICE MANUAL Fig 4 10 30 Series Truck Frame FRAME 2 4 ...

Страница 120: ......

Страница 203: ...ENGINE 6 25 Fig 22L Engine Mounts 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Страница 215: ...ENGINE 6 37 REAR M O U NT Fig 21V Engine Mounts 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Страница 218: ......

Страница 249: ......

Страница 250: ...EMISSION CONTROL SYSTEMS 6T 4 Fig 3 Combination Emission Control System Routing V8 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Страница 324: ......

Страница 339: ...FUEL TANK AND EXHAUST SYSTEMS 8 15 SPECIAL TOOLS Fig 22 Special Tools 1 J 23346 Fuel Tank Gauge Remover and Installer ...

Страница 340: ......

Страница 365: ...10 30 CHEVROLET TRUCK SERVICE MANUAL Fig 43 Power Steering Pump M ounting STEERING 9 25 ...

Страница 368: ......

Страница 386: ......

Страница 390: ...ELECTRICAL BODY AND CHASSIS 12 4 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Страница 391: ......

Страница 392: ...ELECTRICAL BODY AND CHASSIS 12 6 Fig 5 Rear Lighting Composite 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Страница 409: ...ELECTRICAL BODY AND CHASSIS 12 23 Fig 27 Engine Compartment CA30 02 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Страница 410: ...ELECTRICAL BODY AND CHASSIS 12 24 18DK GRN 19 Fig 28 Instrument Panel CA30 02 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Страница 411: ...ELECTRICAL BODY AND CHASSIS 12 25 Fig 29 Instrument Panel CA30 02 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Страница 412: ...ELECTRICAL BODY AND CHASSIS 12 26 fh Ar r kk 4 Fig 30 Engine Compartment C A K A 10 20 CA30 03 z _ ...

Страница 416: ...ELECTRICAL BODY AND CHASSIS 12 30 Fig 34 Engine Compartment CA KA10 20 CA30 04 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Страница 420: ...ELECTRICAL BODY AND CHASSIS 12 34 Fig 38 Engine Compartment C A K A 1 0 20 06 16 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Страница 422: ...ELECTRICAL BODY AND CHASSIS 12 36 Fig 40 Instrument Panel C A K A 10 20 06 16 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Страница 423: ...ELECTRICAL BODY AND CHASSIS 12 37 Fig 41 R ear Lamps C A K A 1 0 20 06 16 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Страница 424: ...ELECTRICAL BODY AND CHASSIS 12 38 Fig 42 Engine Compartment CA KA10 20 CAl30 14 34 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Страница 426: ...ELECTRICAL BODY AND CHASSIS 12 40 Fig 44 Instrument Panel CA KA10 20 CA30 14 34 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Страница 428: ......

Страница 432: ......

Страница 449: ...SPECIFICATIONS 9 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Страница 463: ......

Страница 464: ......

Страница 465: ......

Страница 466: ......