WHEELS AN D TIRES 10-5

Dynamic Balance

Dynamic balance (sometimes called running balance)

means that the wheel must be in static balance, and also

run smoothly at all speeds.

To insure successful, accurate balancing, the following

precautions must be observed:

• Wheel and tire must be clean and free from all

foreign matter.

• The tires should be in good condition and properly

mounted with the balance mark on the tire, if any,

lined up with the valve.

• Bent wheels that have runout over 1/16" should

either be replaced or straightened before being

balanced.

• Inspect tire and wheel assembly to determine if an

eccentric or out-of-round condition exists. Note

that this condition, if severe, cannot be "balanced

out." An assembly which has an out-of-round con

dition exceeding 3/16" on tire sizes through 19.5"

is not suitable for use on the front of the vehicle.

Its use on the rear should be governed by its gen

eral condition and whether the roundness defect

seriously detracts from overall ride quality.

• When balancing wheels and tires, it is recommended

that the instructions covering the operation of the

wheel balancer being used be closely followed.

WHEEL REM OVAL A N D INSTALLATION

Jacking Instructions

The chart will assist in performing wheel and tire

changes using vehicle jacks supplied with or recom

mended for use on Chevrolet Trucks.

Model

Jacking Point on Vehicle

Front

Rear

CP10, 20, 30

Lower Control Arm

Pivot

Axle Housing

K10-20

Under Front Axle

Near Spring Seat

Axle Housing

Dual and Single Wheels

When installing the tire and wheel on the vehicle, the

following procedure should be followed:

After wheel nuts are put on loosely, turn the wheel

until one nut is at the top of the bolt circle; tighten the

nut just snug. Snug up the remaining nuts criss-cross

to minimize runout, then tighten the nuts to the recom

mended torque alternately and evenly to avoid excessive

runout.

Lateral runout should not exceed 1/8" on front wheel

or 3/16" on rear wheel.

Matching Side and Lock Rings

Side and lock rings of different rim types are not inter -

changeable. Some may appear to be, but they do not fit

properly on the rim base. Serious accidents have re

sulted from the use of mismatched rings. Rim base and

rings must be matched according to manufacturer, size

and type. This information is stamped on each part.

Installing Synthetic Tubes

1. Before installing tube in tire, clean inside of casing

thoroughly.

2. Insert tube in tire and inflate until it is nearly

rounded out.

3. Inspect rim for rust scale and bent flanges—clean

rust scale and straighten flanges where necessary.

4. Using a brush or cloth swab, apply a solution of

neutral vegetable oil soap to the inside and outside

of tire beads and also to the rim side of the tube.

Do not allow soap solution to run down into tire.

5. When mounting tire and tube on a drop center rim,

follow the standard procedure. Be sure tire is cen

tered on rim so that beads are out of rim well before

inflating. Do not allow tire to hang loosely on wheel

while inflating.

6. Center valve and pull it firmly against the rim. Hold

in this position and inflate until tire beads are firmly

seated on rim against flanges.

7. Completely deflate tire by removing valve core.

8. Reinflate tire to recommended pressure.

CAUTION:

When tube and flap are not properly

lubricated and mounted, they will stretch thin

in the tire bead and rim region. This will cause

premature failure.

TUBELESS TIRES

Tubeless tires mounted on one piece full drop center

rims are standard on some Chevrolet trucks. These

tires have a safety inner liner which if punctured, tends

to cling to the penetrating object forming a partial seal

until the object is removed from the tire.

The mounting and demounting of tubeless truck tires

will present no problem when a rubber lubricant, such as

Ru-Glyde or equivalent is applied to tire beads and rim

flanges. Ru-Glyde or equivalent in addition to materially

assisting in mounting and demounting also prevents rust

ing at the tire sealing area and thus prevents tires from

adhering to the wheel.

All tubeless tires used on Chevrolet trucks with the

exception of the 6.50-16 size should be demounted and

mounted as described in this section. The 6.50-16 size

may be demounted using present tire machines or stand

ard tire irons following the same procedure employed in

servicing tube type tires.

CAUTION:

A hammer, or tools with sharp

edges, should never be used to demount or mount

tubeless tires as damage to rim flange or tire

sealing bead may result.

Inspection for Leaks

1. With wheel assembly removed from vehicle, inflate

the tire to recommended operating pressure.

2. Check for leaks at rim bead by placing wheel and tire

horizontal and allowing water to stand in groove be

tween rim and tire. Check for large leads by lower

ing assembly into water tank or running water over

tire.

Demounting (all except 6.50-16 tires)

1. Remove valve core to completely deflate tire. With

tire lying flat on floor, loosen beads from rim seats

by walking around on tire with heels at points close

10-30 CHEVROLET TRUCK SERVICE MANUAL

Содержание 10 1971 Series

Страница 1: ......

Страница 96: ......

Страница 100: ...10 30 CHEVROLET TRUCK SERVICE MANUAL Fig 4 10 30 Series Truck Frame FRAME 2 4 ...

Страница 120: ......

Страница 203: ...ENGINE 6 25 Fig 22L Engine Mounts 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Страница 215: ...ENGINE 6 37 REAR M O U NT Fig 21V Engine Mounts 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Страница 218: ......

Страница 249: ......

Страница 250: ...EMISSION CONTROL SYSTEMS 6T 4 Fig 3 Combination Emission Control System Routing V8 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Страница 324: ......

Страница 339: ...FUEL TANK AND EXHAUST SYSTEMS 8 15 SPECIAL TOOLS Fig 22 Special Tools 1 J 23346 Fuel Tank Gauge Remover and Installer ...

Страница 340: ......

Страница 365: ...10 30 CHEVROLET TRUCK SERVICE MANUAL Fig 43 Power Steering Pump M ounting STEERING 9 25 ...

Страница 368: ......

Страница 386: ......

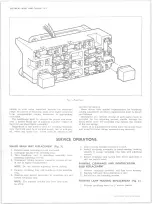

Страница 390: ...ELECTRICAL BODY AND CHASSIS 12 4 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Страница 391: ......

Страница 392: ...ELECTRICAL BODY AND CHASSIS 12 6 Fig 5 Rear Lighting Composite 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Страница 409: ...ELECTRICAL BODY AND CHASSIS 12 23 Fig 27 Engine Compartment CA30 02 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Страница 410: ...ELECTRICAL BODY AND CHASSIS 12 24 18DK GRN 19 Fig 28 Instrument Panel CA30 02 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Страница 411: ...ELECTRICAL BODY AND CHASSIS 12 25 Fig 29 Instrument Panel CA30 02 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Страница 412: ...ELECTRICAL BODY AND CHASSIS 12 26 fh Ar r kk 4 Fig 30 Engine Compartment C A K A 10 20 CA30 03 z _ ...

Страница 416: ...ELECTRICAL BODY AND CHASSIS 12 30 Fig 34 Engine Compartment CA KA10 20 CA30 04 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Страница 420: ...ELECTRICAL BODY AND CHASSIS 12 34 Fig 38 Engine Compartment C A K A 1 0 20 06 16 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Страница 422: ...ELECTRICAL BODY AND CHASSIS 12 36 Fig 40 Instrument Panel C A K A 10 20 06 16 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Страница 423: ...ELECTRICAL BODY AND CHASSIS 12 37 Fig 41 R ear Lamps C A K A 1 0 20 06 16 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Страница 424: ...ELECTRICAL BODY AND CHASSIS 12 38 Fig 42 Engine Compartment CA KA10 20 CAl30 14 34 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Страница 426: ...ELECTRICAL BODY AND CHASSIS 12 40 Fig 44 Instrument Panel CA KA10 20 CA30 14 34 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Страница 428: ......

Страница 432: ......

Страница 449: ...SPECIFICATIONS 9 10 30 CHEVROLET TRUCK SERVICE MANUAL ...

Страница 463: ......

Страница 464: ......

Страница 465: ......

Страница 466: ......