7 - 16

FI

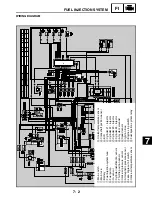

FUEL INJECTION SYSTEM

Troubleshooting details

Troubleshooting the self-diagnostic fault code

Code No.

11

Symptom

No normal signals are received from the cylinder identification sensor.

Used diagnostic code No.

Inspection operation item

Operation item and countermeasure

Reinstatement

method

Installed state of sensor

Check the installed area for looseness or

pinching.

Reinstated by

starting the engine

and operating it at

idle.

Defective cylinder identification sensor.

Replace if defective.

Refer to “FUEL INJECTION SYSTEM” in

chapter 8.

Open or short circuit in wiring harness or sub

lead.

Repair or replace if there is an open or short

circuit.

Between main wiring harness and sub lead

Blue - Blue

White/Black - White

Black/Blue - Black/Blue

Connected state of connector

Inspect the coupler for any pins that may

have pulled out.

Check the locking condition of the coupler.

If there is a malfunction, repair it and connect it

securely.

Cylinder identification sensor coupler

Main wiring harness ECU coupler

Sub-wire harness coupler

Code No.

12

Symptom

No normal signals are received from the crankshaft position sensor.

Used diagnostic code No.

Inspection operation item and probable cause Operation item and countermeasure

Reinstatement

method

Installed state of sensor

Check the installed area for looseness or

pinching.

Reinstated by

cranking the

engine.

Defective crankshaft position sensor.

Replace if defective.

Refer to “FUEL INJECTION SYSTEM” in

chapter 8.

Open or short circuit in wiring harness or sub

lead.

Repair or replace if there is an open or short

circuit between the main wiring harnesses.

Gray - Gray

Black/Blue - Black/Blue

Connected state of connector

Inspect the coupler for any pins that may

have pulled out.

Check the locking condition of the coupler.

If there is a malfunction, repair it and connect it

securely.

Crankshaft position sensor coupler

Main wiring harness ECU coupler

Summary of Contents for FJR1300

Page 1: ...LIT 11616 16 18 5JW 28197 10 FJR1300R FJR1300RC SERVICE MANUAL ...

Page 6: ......

Page 82: ...2 22 SPEC TIGHTENING TORQUES Cylinder head tightening sequence Crankcase tightening sequence ...

Page 89: ...2 29 SPEC 1 Crankshaft 2 Main axle 3 Drive axle OIL FLOW DIAGRAMS ...

Page 90: ...2 30 SPEC 1 Oil nozzle 2 Main gallery bolt 3 Crankshaft OIL FLOW DIAGRAMS ...

Page 91: ...2 31 SPEC 1 Main axle 2 Drive axle 3 Oil delivery pipe OIL FLOW DIAGRAMS ...

Page 92: ...2 32 SPEC 1 Exhaust camshaft 2 Oil check bolt 3 Intake camshaft OIL FLOW DIAGRAMS ...

Page 94: ...2 34 SPEC 1 Crank pin 2 Crankshaft OIL FLOW DIAGRAMS ...

Page 97: ...2 37 SPEC 1 Main axle 2 Drive axle 3 Middle drive shaft OIL FLOW DIAGRAMS ...

Page 98: ...2 38 SPEC COOLING SYSTEM DIAGRAMS 1 Radiator COOLING SYSTEM DIAGRAMS ...

Page 99: ...2 39 SPEC 1 Water jacket joint 2 Oil cooler COOLING SYSTEM DIAGRAMS ...

Page 101: ...2 41 SPEC 1 Coolant reservoir 2 Radiator 3 Water pump COOLING SYSTEM DIAGRAMS ...

Page 107: ...2 47 SPEC CABLE ROUTING 1 Tail brake light lead ...

Page 196: ...3 80 CHK ADJ ADJUSTING THE HEADLIGHT BEAMS ...

Page 288: ...4 92 CHAS 3 Install bearing 1 to the swingarm Installed depth a 4 0 mm 0 16 in SWINGARM ...

Page 531: ...8 35 ELEC LIGHTING SYSTEM ...

Page 570: ......

Page 571: ...YAMAHA MOTOR CO LTD 2500 SHINGAI IWATA SHIZUOKA JAPAN PRINTED IN U S A ...