5 - 93

ENG

3. Remove:

• top ring

• 2nd ring

• oil ring

NOTE:

@

When removing a piston ring, open the end

gap with your fingers and lift the other side of

the ring over the piston crown.

EAS00258

CHECKING THE CYLINDERS AND

PISTONS

The following procedure applies to all of the

cylinders and pistons.

1. Check:

• piston wall

• cylinder wall

Vertical scratches

→

Replace the cylinder,

and the piston and piston rings as a set.

2. Measure:

• piston-to-cylinder clearance

▼▼▼

▼

▼ ▼▼▼

▼

▼ ▼▼▼

▼

▼ ▼▼▼

▼

▼ ▼▼▼

▼

▼ ▼▼▼

▼

▼▼▼

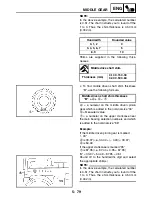

a. Measure cylinder bore “C” with the cylinder

bore gauge.

NOTE:

@

Measure cylinder bore “C” by taking side-to-

side and front-to-back measurements of the

cylinder. Then, find the average of the mea-

surements.

b. If out of specification, replace the cylinder,

and the piston and piston rings as a set.

Cylinder bore “C”

79.00 ~ 79.01 mm

(3.1102 ~ 3.1106 in)

Taper limit “T”

0.05 mm (0.002 in)

Out of round “R”

0.05 mm (0.002 in)

“C” = maximum of D

1

~ D

6

“T” = maximum of D

1

or D

2

– maximum of

D

5

or D

6

“R” = maximum of D

1

, D

3

or D

5

– mini-

mum of D

2

, D

4

or D

6

CONNECTING RODS AND PISTONS

Summary of Contents for FJR1300

Page 1: ...LIT 11616 16 18 5JW 28197 10 FJR1300R FJR1300RC SERVICE MANUAL ...

Page 6: ......

Page 82: ...2 22 SPEC TIGHTENING TORQUES Cylinder head tightening sequence Crankcase tightening sequence ...

Page 89: ...2 29 SPEC 1 Crankshaft 2 Main axle 3 Drive axle OIL FLOW DIAGRAMS ...

Page 90: ...2 30 SPEC 1 Oil nozzle 2 Main gallery bolt 3 Crankshaft OIL FLOW DIAGRAMS ...

Page 91: ...2 31 SPEC 1 Main axle 2 Drive axle 3 Oil delivery pipe OIL FLOW DIAGRAMS ...

Page 92: ...2 32 SPEC 1 Exhaust camshaft 2 Oil check bolt 3 Intake camshaft OIL FLOW DIAGRAMS ...

Page 94: ...2 34 SPEC 1 Crank pin 2 Crankshaft OIL FLOW DIAGRAMS ...

Page 97: ...2 37 SPEC 1 Main axle 2 Drive axle 3 Middle drive shaft OIL FLOW DIAGRAMS ...

Page 98: ...2 38 SPEC COOLING SYSTEM DIAGRAMS 1 Radiator COOLING SYSTEM DIAGRAMS ...

Page 99: ...2 39 SPEC 1 Water jacket joint 2 Oil cooler COOLING SYSTEM DIAGRAMS ...

Page 101: ...2 41 SPEC 1 Coolant reservoir 2 Radiator 3 Water pump COOLING SYSTEM DIAGRAMS ...

Page 107: ...2 47 SPEC CABLE ROUTING 1 Tail brake light lead ...

Page 196: ...3 80 CHK ADJ ADJUSTING THE HEADLIGHT BEAMS ...

Page 288: ...4 92 CHAS 3 Install bearing 1 to the swingarm Installed depth a 4 0 mm 0 16 in SWINGARM ...

Page 531: ...8 35 ELEC LIGHTING SYSTEM ...

Page 570: ......

Page 571: ...YAMAHA MOTOR CO LTD 2500 SHINGAI IWATA SHIZUOKA JAPAN PRINTED IN U S A ...