8 - 49

–

+

ELEC

COOLING SYSTEM

EAS00811

YES

NO

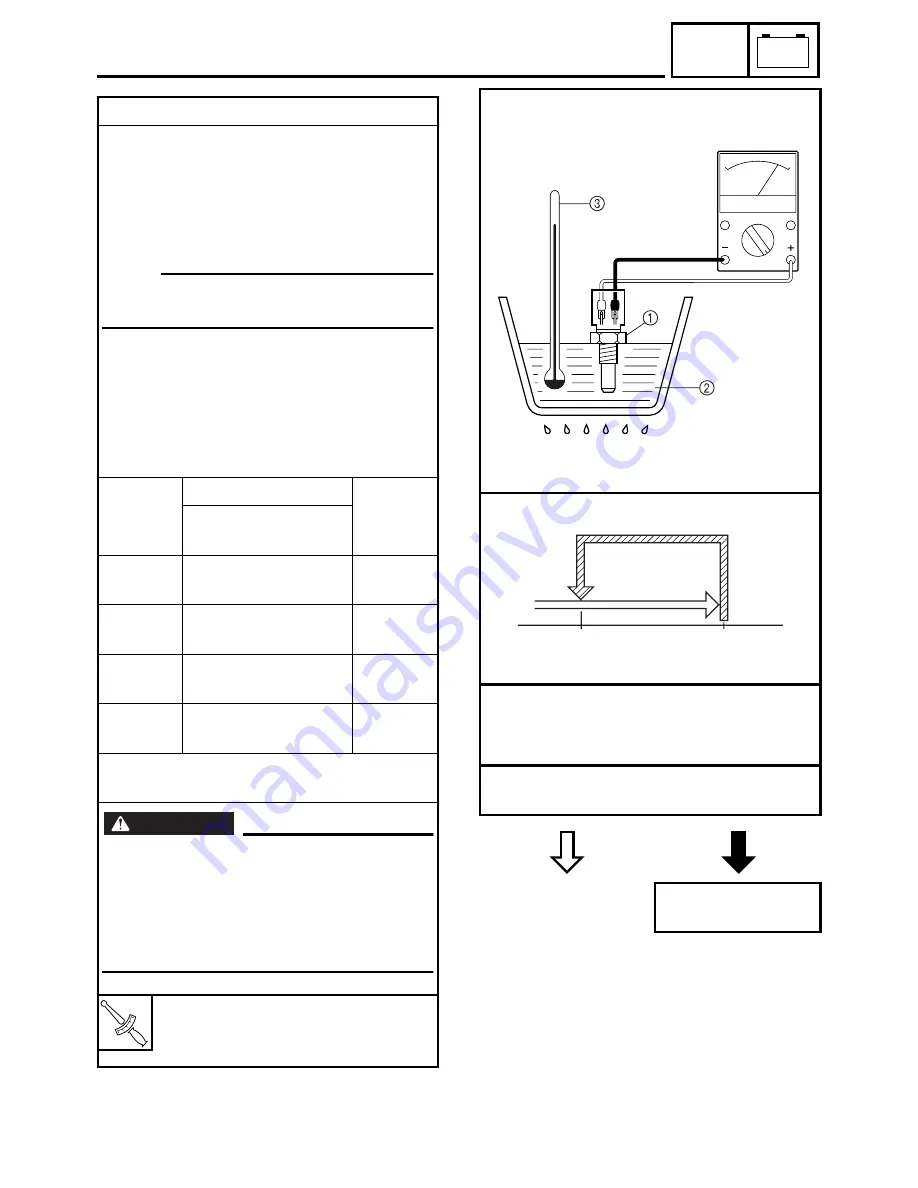

7. Coolant temperature sensor

• Remove the coolant temperature sensor

from the thermostat assembly inlet pipe.

• Connect the pocket tester (

Ω

×

1) to the

coolant temperature sensor

1

as shown.

• Immerse the coolant temperature sensor in

a container filled with coolant

2

.

NOTE:

Make sure that the coolant temperature sen-

sor terminals do not get wet.

• Place a thermometer

3

in the coolant.

• Slowly heat the coolant, then let it cool

down to the specified temperature.

• Check the coolant temperature sensor for

continuity at the temperatures indicated

below.

Test step

Coolant temperature

Continu-

ity

Coolant temperature

sensor

1

Less than 105 °C

(221 °F)

NO

2

More than 105 °C

(221 °F)

YES

3

More than 100 °C

(212 °F)

YES

4

Less than 100 °C

(212 °F)

NO

Test steps 1 & 2: Heating phase

Test steps 3 & 4: Cooling phase

WARNING

@

• Handle the coolant temperature sensor

with special care.

• Never subject the coolant temperature

sensor to strong shocks. If the coolant

temperature sensor is dropped, replace

it.

T

R

.

.

Coolant temperature sensor

20 Nm (2.0 m · kg, 14 ft · lb)

Three bond sealock

®

10

È

The coolant temperature sensor circuit is open

and the radiator fan is off.

É

The coolant temperature sensor circuit is

closed and the radiator fan is on.

• Does the

coolant temperature sensor

operate

properly as described above?

Replace the

coolant

temperature sensor

.

100 ˚C

(212 ˚F)

105 ˚C

(221 ˚F)

È

É

Summary of Contents for FJR1300

Page 1: ...LIT 11616 16 18 5JW 28197 10 FJR1300R FJR1300RC SERVICE MANUAL ...

Page 6: ......

Page 82: ...2 22 SPEC TIGHTENING TORQUES Cylinder head tightening sequence Crankcase tightening sequence ...

Page 89: ...2 29 SPEC 1 Crankshaft 2 Main axle 3 Drive axle OIL FLOW DIAGRAMS ...

Page 90: ...2 30 SPEC 1 Oil nozzle 2 Main gallery bolt 3 Crankshaft OIL FLOW DIAGRAMS ...

Page 91: ...2 31 SPEC 1 Main axle 2 Drive axle 3 Oil delivery pipe OIL FLOW DIAGRAMS ...

Page 92: ...2 32 SPEC 1 Exhaust camshaft 2 Oil check bolt 3 Intake camshaft OIL FLOW DIAGRAMS ...

Page 94: ...2 34 SPEC 1 Crank pin 2 Crankshaft OIL FLOW DIAGRAMS ...

Page 97: ...2 37 SPEC 1 Main axle 2 Drive axle 3 Middle drive shaft OIL FLOW DIAGRAMS ...

Page 98: ...2 38 SPEC COOLING SYSTEM DIAGRAMS 1 Radiator COOLING SYSTEM DIAGRAMS ...

Page 99: ...2 39 SPEC 1 Water jacket joint 2 Oil cooler COOLING SYSTEM DIAGRAMS ...

Page 101: ...2 41 SPEC 1 Coolant reservoir 2 Radiator 3 Water pump COOLING SYSTEM DIAGRAMS ...

Page 107: ...2 47 SPEC CABLE ROUTING 1 Tail brake light lead ...

Page 196: ...3 80 CHK ADJ ADJUSTING THE HEADLIGHT BEAMS ...

Page 288: ...4 92 CHAS 3 Install bearing 1 to the swingarm Installed depth a 4 0 mm 0 16 in SWINGARM ...

Page 531: ...8 35 ELEC LIGHTING SYSTEM ...

Page 570: ......

Page 571: ...YAMAHA MOTOR CO LTD 2500 SHINGAI IWATA SHIZUOKA JAPAN PRINTED IN U S A ...