8 - 17

–

+

ELEC

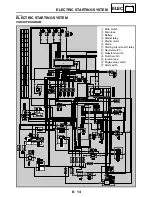

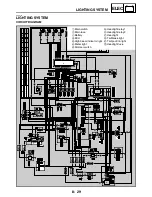

ELECTRIC STARTING SYSTEM

EAS00759

YES

NO

EAS00760

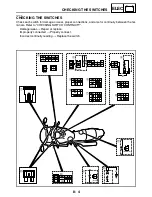

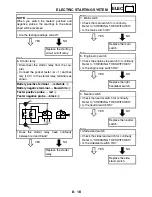

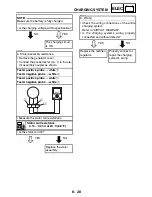

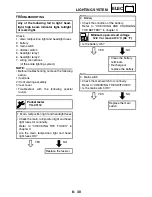

4. Starting circuit cut-off relay

• Disconnect the starting circuit cut-off relay

from the wire harness.

• Connect the pocket tester (

Ω

×

1) and bat-

tery (12 V) to the starting circuit cut-off relay

terminals as shown.

Battery positive terminal

→

red/black

1

Battery negative terminal

→

black/yellow

2

Tester positive probe

→

blue/white

3

Tester negative probe

→

black

4

• Does the starting circuit cut-off relay have

continuity between blue/white and black?

Replace the starting

circuit cut-off relay.

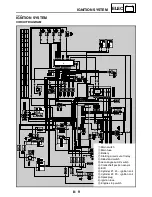

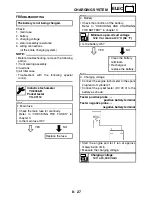

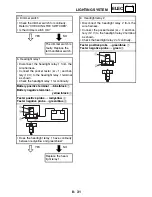

5. Starting circuit cut-off relay (diode)

• Disconnect the starting circuit cut-off relay

from the wire harness.

• Connect the pocket tester (

Ω

×

1) to the

starting circuit cut-off relay terminals as

shown.

• Measure the starting circuit cut-off relay for

continuity as follows.

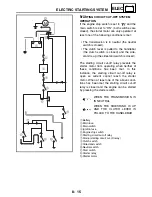

Lg

L

/

G L

/

Y Sb B

/

Y

B

R

/

B L

/

W

+

Tester positive probe

→

sky blue

1

Tester negative probe

→

light green

2

Continu-

ity

Tester positive probe

→

sky blue

1

Tester negative probe

→

black/yellow

3

Tester positive probe

→

sky blue

1

Tester negative probe

→

blue/yellow

4

Tester positive probe

→

blue/green

5

Tester negative probe

→

blue/yellow

4

Tester positive probe

→

light green

2

Tester negative probe

→

sky blue

1

No conti-

nuity

Tester positive probe

→

black/yellow

3

Tester negative probe

→

sky blue

1

Tester positive probe

→

blue/yellow

4

Tester negative probe

→

sky blue

1

Tester positive probe

→

blue/yellow

4

Tester negative probe

→

blue/green

5

Lg

L

/

G L

/

Y Sb B

/

Y

B

R

/

B L

/

W

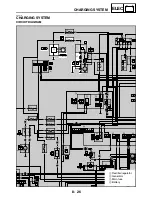

Summary of Contents for FJR1300

Page 1: ...LIT 11616 16 18 5JW 28197 10 FJR1300R FJR1300RC SERVICE MANUAL ...

Page 6: ......

Page 82: ...2 22 SPEC TIGHTENING TORQUES Cylinder head tightening sequence Crankcase tightening sequence ...

Page 89: ...2 29 SPEC 1 Crankshaft 2 Main axle 3 Drive axle OIL FLOW DIAGRAMS ...

Page 90: ...2 30 SPEC 1 Oil nozzle 2 Main gallery bolt 3 Crankshaft OIL FLOW DIAGRAMS ...

Page 91: ...2 31 SPEC 1 Main axle 2 Drive axle 3 Oil delivery pipe OIL FLOW DIAGRAMS ...

Page 92: ...2 32 SPEC 1 Exhaust camshaft 2 Oil check bolt 3 Intake camshaft OIL FLOW DIAGRAMS ...

Page 94: ...2 34 SPEC 1 Crank pin 2 Crankshaft OIL FLOW DIAGRAMS ...

Page 97: ...2 37 SPEC 1 Main axle 2 Drive axle 3 Middle drive shaft OIL FLOW DIAGRAMS ...

Page 98: ...2 38 SPEC COOLING SYSTEM DIAGRAMS 1 Radiator COOLING SYSTEM DIAGRAMS ...

Page 99: ...2 39 SPEC 1 Water jacket joint 2 Oil cooler COOLING SYSTEM DIAGRAMS ...

Page 101: ...2 41 SPEC 1 Coolant reservoir 2 Radiator 3 Water pump COOLING SYSTEM DIAGRAMS ...

Page 107: ...2 47 SPEC CABLE ROUTING 1 Tail brake light lead ...

Page 196: ...3 80 CHK ADJ ADJUSTING THE HEADLIGHT BEAMS ...

Page 288: ...4 92 CHAS 3 Install bearing 1 to the swingarm Installed depth a 4 0 mm 0 16 in SWINGARM ...

Page 531: ...8 35 ELEC LIGHTING SYSTEM ...

Page 570: ......

Page 571: ...YAMAHA MOTOR CO LTD 2500 SHINGAI IWATA SHIZUOKA JAPAN PRINTED IN U S A ...