7 - 7

FI

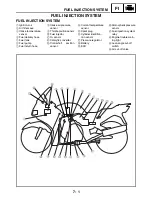

FUEL INJECTION SYSTEM

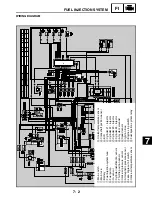

SUBSTITUTE CHARACTERISTICS OPERATION CONTROL (FAIL-SAFE ACTION)

If the ECU detects an abnormal signal from a sensor while the motorcycle is being driven, the ECU

illuminates the engine trouble warning light and provides the engine with substitute characteristic

operation instructions that are appropriate for the type of the malfunction.

When an abnormal signal is received from a sensor, the ECU processes the specified values that

are programmed for every sensor, in order to provide the engine with substitute characteristics

operation instructions that enable the engine to continue to operate (or to stop its operation,

depending on circumstances).

The ECU takes fail-safe actions in two ways: one in which the sensor output is set to a prescribed

value, and the other in which the ECU directly operates an actuator. Details on the fail-safe actions

are given in the table below.

Table of substitute characteristic operation control by self-diagnostic fault code

Code No.

Item

Fail-safe action

Able/unable to

start

Able/unable to

drive

11

Cylinder identification

sensor

Continues to operate the engine based on the results

of the cylinder identification that existed up to that

point.

Able

Able

12

Crankshaft position sen-

sor

• Stops the engine (by stopping the injection and

ignition).

Unable

Unable

13

14

Intake air pressure sensor

(open or short circuit)

(pipe system)

• Fixes the intake air pressure to 760 mm Hg

(29.92 in Hg).

Able

Able

15

16

Throttle position sensor

(open or short circuit)

(stuck)

• Fixes the throttle position sensor to fully open.

Able

Able

19

Sidestand switch

(open circuit in wire to

ECU)

-- (No start)

Unable

Unable

21

Coolant temperature sen-

sor

• Fixes the coolant temperature to 60 °C (140 °F).

Able

Able

22

Intake temperature sen-

sor

• Fixes the intake temperature to 20 °C (68 °F).

Able

Able

23

Atmospheric pressure

sensor

• Fixes the atmospheric pressure to 760 mm Hg

(29.92 in Hg).

Able

Able

24

31

32

O

2

sensor

(inactive)

(compensation stuck to

upper limit)

(compensation stuck to

lower limit)

--

Able

Able

33

34

Faulty ignition

• Fuel is cut off only to the cylinder in which a mal-

function is detected.

Able

(depending on

the number of

faulty cylinders)

Able

(depending on

the number of

faulty cylinders)

30

41

Lean angle cut-off switch

(latch up detected)

(open or short circuit)

• Turns OFF the fuel injection system relay of the fuel

system.

Unable

Unable

42

Speed sensor, neutral

switch

• Fixes the gear to the top gear.

Able

Able

43

Fuel system voltage

(monitor voltage)

• Fixes the battery voltage to 12 V.

Able

Able

50

ECU internal malfunction

(memory check error)

--

Unable

Unable

Summary of Contents for FJR1300

Page 1: ...LIT 11616 16 18 5JW 28197 10 FJR1300R FJR1300RC SERVICE MANUAL ...

Page 6: ......

Page 82: ...2 22 SPEC TIGHTENING TORQUES Cylinder head tightening sequence Crankcase tightening sequence ...

Page 89: ...2 29 SPEC 1 Crankshaft 2 Main axle 3 Drive axle OIL FLOW DIAGRAMS ...

Page 90: ...2 30 SPEC 1 Oil nozzle 2 Main gallery bolt 3 Crankshaft OIL FLOW DIAGRAMS ...

Page 91: ...2 31 SPEC 1 Main axle 2 Drive axle 3 Oil delivery pipe OIL FLOW DIAGRAMS ...

Page 92: ...2 32 SPEC 1 Exhaust camshaft 2 Oil check bolt 3 Intake camshaft OIL FLOW DIAGRAMS ...

Page 94: ...2 34 SPEC 1 Crank pin 2 Crankshaft OIL FLOW DIAGRAMS ...

Page 97: ...2 37 SPEC 1 Main axle 2 Drive axle 3 Middle drive shaft OIL FLOW DIAGRAMS ...

Page 98: ...2 38 SPEC COOLING SYSTEM DIAGRAMS 1 Radiator COOLING SYSTEM DIAGRAMS ...

Page 99: ...2 39 SPEC 1 Water jacket joint 2 Oil cooler COOLING SYSTEM DIAGRAMS ...

Page 101: ...2 41 SPEC 1 Coolant reservoir 2 Radiator 3 Water pump COOLING SYSTEM DIAGRAMS ...

Page 107: ...2 47 SPEC CABLE ROUTING 1 Tail brake light lead ...

Page 196: ...3 80 CHK ADJ ADJUSTING THE HEADLIGHT BEAMS ...

Page 288: ...4 92 CHAS 3 Install bearing 1 to the swingarm Installed depth a 4 0 mm 0 16 in SWINGARM ...

Page 531: ...8 35 ELEC LIGHTING SYSTEM ...

Page 570: ......

Page 571: ...YAMAHA MOTOR CO LTD 2500 SHINGAI IWATA SHIZUOKA JAPAN PRINTED IN U S A ...