5 - 77

ENG

7. Select:

• shim(s)

1

▼▼▼

▼

▼ ▼▼▼

▼

▼ ▼▼▼

▼

▼ ▼▼▼

▼

▼ ▼▼▼

▼

▼ ▼▼▼

▼

▼▼▼

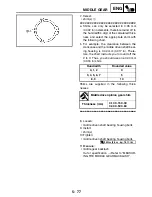

a. Shims can only be selected in 0.05 mm

(0.002 in) increments, therefore round off to

the hundredth’s digit of the calculated thick-

ness and select the appropriate shim with

the following chart.

b. For example, the clearance between the

crankcase and the middle driven shaft bear-

ing housing is 0.42 mm (0.017 in). There-

fore, the chart instructs you to round off the

2 to 0. Thus, you should use one 0.40 mm

(0.016 in) shim.

Shims are supplied in the following thick-

nesses.

▲▲▲

▲

▲ ▲▲▲

▲

▲ ▲▲▲

▲

▲ ▲▲▲

▲

▲ ▲▲▲

▲

▲ ▲▲▲

▲

▲▲▲

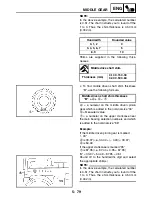

Hundredth

Rounded value

0, 1, 2

0

3, 4, 5, 6, 7

5

8, 9

10

Middle driven pinion gear shim

Thickness (mm)

0.10 0.15 0.30

0.40 0.50 0.60

8. Loosen:

• middle driven shaft bearing housing bolts

9. Install:

• shim(s)

10.Tighten:

• middle driven shaft bearing housing bolts

11.Measure:

• middle gear backlash

Out of specification

→

Refer to “MEASUR-

ING THE MIDDLE GEAR BACKLASH”.

T

R

.

.

25 Nm (2.5 m · kg, 18 ft · lb)

MIDDLE GEAR

Summary of Contents for FJR1300

Page 1: ...LIT 11616 16 18 5JW 28197 10 FJR1300R FJR1300RC SERVICE MANUAL ...

Page 6: ......

Page 82: ...2 22 SPEC TIGHTENING TORQUES Cylinder head tightening sequence Crankcase tightening sequence ...

Page 89: ...2 29 SPEC 1 Crankshaft 2 Main axle 3 Drive axle OIL FLOW DIAGRAMS ...

Page 90: ...2 30 SPEC 1 Oil nozzle 2 Main gallery bolt 3 Crankshaft OIL FLOW DIAGRAMS ...

Page 91: ...2 31 SPEC 1 Main axle 2 Drive axle 3 Oil delivery pipe OIL FLOW DIAGRAMS ...

Page 92: ...2 32 SPEC 1 Exhaust camshaft 2 Oil check bolt 3 Intake camshaft OIL FLOW DIAGRAMS ...

Page 94: ...2 34 SPEC 1 Crank pin 2 Crankshaft OIL FLOW DIAGRAMS ...

Page 97: ...2 37 SPEC 1 Main axle 2 Drive axle 3 Middle drive shaft OIL FLOW DIAGRAMS ...

Page 98: ...2 38 SPEC COOLING SYSTEM DIAGRAMS 1 Radiator COOLING SYSTEM DIAGRAMS ...

Page 99: ...2 39 SPEC 1 Water jacket joint 2 Oil cooler COOLING SYSTEM DIAGRAMS ...

Page 101: ...2 41 SPEC 1 Coolant reservoir 2 Radiator 3 Water pump COOLING SYSTEM DIAGRAMS ...

Page 107: ...2 47 SPEC CABLE ROUTING 1 Tail brake light lead ...

Page 196: ...3 80 CHK ADJ ADJUSTING THE HEADLIGHT BEAMS ...

Page 288: ...4 92 CHAS 3 Install bearing 1 to the swingarm Installed depth a 4 0 mm 0 16 in SWINGARM ...

Page 531: ...8 35 ELEC LIGHTING SYSTEM ...

Page 570: ......

Page 571: ...YAMAHA MOTOR CO LTD 2500 SHINGAI IWATA SHIZUOKA JAPAN PRINTED IN U S A ...