4 - 49

CHAS

EAS00307

CAUTION:

@

Clutch components rarely require disas-

sembly.

Therefore, always follow these preventive

measures:

• Never disassemble clutch components

unless absolutely necessary.

• If any connection on the hydraulic clutch

system is disconnected, the entire clutch

system must be disassembled, drained,

cleaned, properly filled, and bled after

reassembly.

• Never use solvents on internal clutch

components.

• Use only clean or new clutch fluid for

cleaning clutch components.

• Clutch fluid may damage painted sur-

faces and plastic parts. Therefore, always

clean up any spilt fluid immediately.

• Avoid clutch fluid coming into contact

with the eyes as it can cause serious

injury.

• First aid for clutch fluid entering the eyes:

• Flush with water for 15 minutes and get

immediate medical attention.

DISASSEMBLING THE CLUTCH MASTER

CYLINDER

NOTE:

Before disassembling the clutch master cylin-

der, drain the clutch fluid from the entire clutch

system.

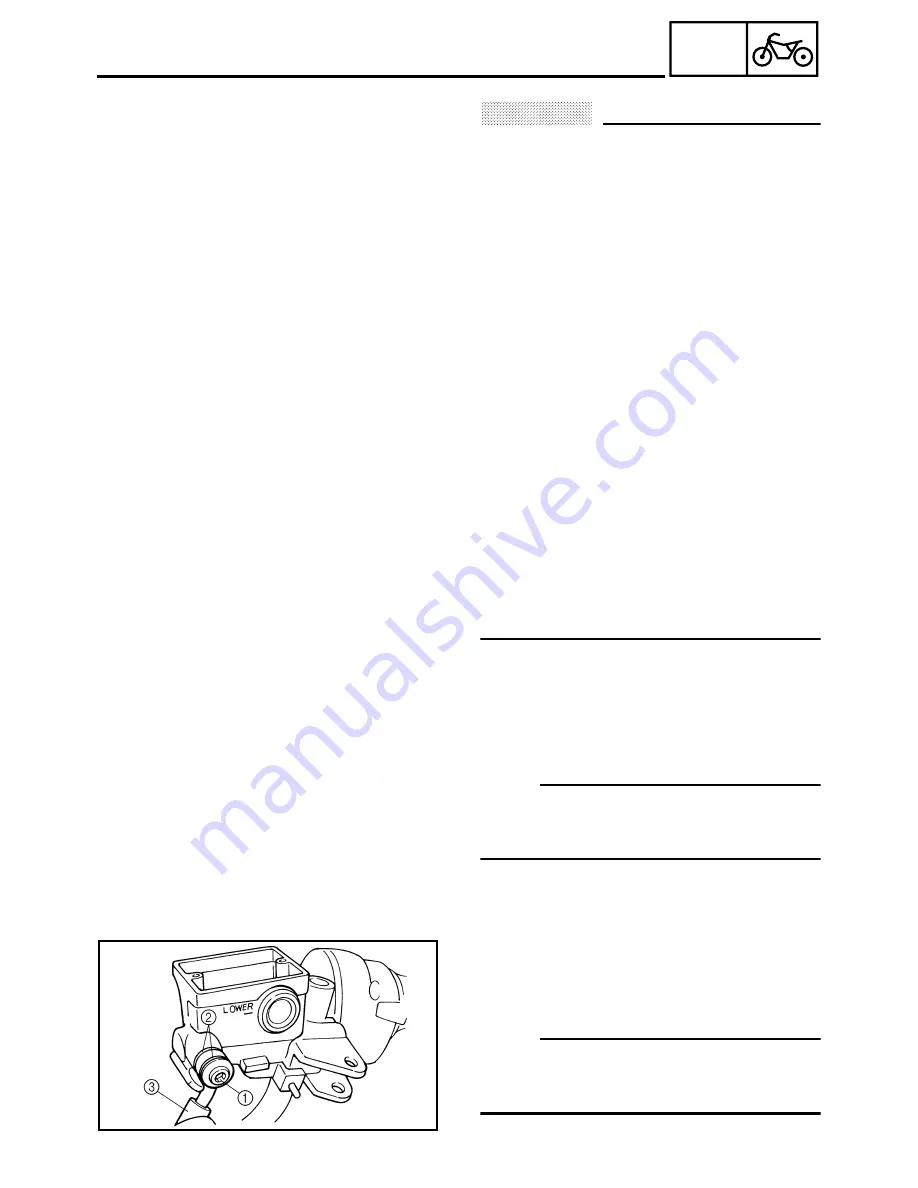

1. Remove:

• union bolt

1

• copper washers

2

• clutch hose

3

NOTE:

To collect any remaining clutch fluid, place a

container under the master cylinder and the

end of the clutch hose.

HYDRAULIC CLUTCH

Summary of Contents for FJR1300

Page 1: ...LIT 11616 16 18 5JW 28197 10 FJR1300R FJR1300RC SERVICE MANUAL ...

Page 6: ......

Page 82: ...2 22 SPEC TIGHTENING TORQUES Cylinder head tightening sequence Crankcase tightening sequence ...

Page 89: ...2 29 SPEC 1 Crankshaft 2 Main axle 3 Drive axle OIL FLOW DIAGRAMS ...

Page 90: ...2 30 SPEC 1 Oil nozzle 2 Main gallery bolt 3 Crankshaft OIL FLOW DIAGRAMS ...

Page 91: ...2 31 SPEC 1 Main axle 2 Drive axle 3 Oil delivery pipe OIL FLOW DIAGRAMS ...

Page 92: ...2 32 SPEC 1 Exhaust camshaft 2 Oil check bolt 3 Intake camshaft OIL FLOW DIAGRAMS ...

Page 94: ...2 34 SPEC 1 Crank pin 2 Crankshaft OIL FLOW DIAGRAMS ...

Page 97: ...2 37 SPEC 1 Main axle 2 Drive axle 3 Middle drive shaft OIL FLOW DIAGRAMS ...

Page 98: ...2 38 SPEC COOLING SYSTEM DIAGRAMS 1 Radiator COOLING SYSTEM DIAGRAMS ...

Page 99: ...2 39 SPEC 1 Water jacket joint 2 Oil cooler COOLING SYSTEM DIAGRAMS ...

Page 101: ...2 41 SPEC 1 Coolant reservoir 2 Radiator 3 Water pump COOLING SYSTEM DIAGRAMS ...

Page 107: ...2 47 SPEC CABLE ROUTING 1 Tail brake light lead ...

Page 196: ...3 80 CHK ADJ ADJUSTING THE HEADLIGHT BEAMS ...

Page 288: ...4 92 CHAS 3 Install bearing 1 to the swingarm Installed depth a 4 0 mm 0 16 in SWINGARM ...

Page 531: ...8 35 ELEC LIGHTING SYSTEM ...

Page 570: ......

Page 571: ...YAMAHA MOTOR CO LTD 2500 SHINGAI IWATA SHIZUOKA JAPAN PRINTED IN U S A ...