7 - 9

FI

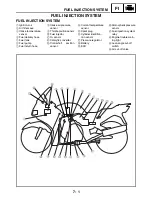

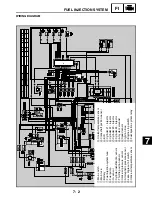

FUEL INJECTION SYSTEM

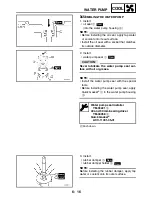

Verifying the operation of various sensors and

actuators

1. Disconnect the wiring harness coupler from

the fuel pump.

2. Turn the engine stop switch “OFF”.

· Turn the engine stop switch “ON” if diag-

nostic code numbers 03 and 09 are

shown.

3. Select the diagnostic code number that

applies to the item that was verified with the

self-diagnostic fault code number, and

enter it on the meter by operating the

“SELECT” or “RESET” button.

* “RESET” button

Decrement (press 1 second or longer

→

auto)

“SELECT” button

Increment (press 1 second or longer

→

auto)

* Diagnostic code number appears on clock

LCD (01 ~ 70)

4. Verifying the operation of the displayed

diagnostic code

· Verifying various sensors

The data representing the operating con-

ditions of the sensors appears on the trip

LCD (throttle position sensor angle, cool-

ant temperature, atmospheric pressure,

etc.)

· Verifying the operation of actuators

Start the operation by turning the stop

switch “ON” (injectors, relay, ignition coil,

AIS, etc.)

* If the stop switch is “ON”, turn it “OFF”;

then, turn it back “ON”.

5. Check the results by referring to the sensor

operation data verification table or the actu-

ator operation verification table.

Perform individual repairs on the areas where

malfunctions have been identified.

F

L

L

H

E

SELECT

RESET

TRIP

TRIP

km

mile

km

mile

000

F

L

L

H

E

SELECT

RESET

TRIP

TRIP

km

mile

km

mile

000

F

L

L

H

E

SELECT

RESET

TRIP

TRIP

km

mile

km

mile

000

SELECT

(01 70)

RESET

(01 70)

Summary of Contents for FJR1300

Page 1: ...LIT 11616 16 18 5JW 28197 10 FJR1300R FJR1300RC SERVICE MANUAL ...

Page 6: ......

Page 82: ...2 22 SPEC TIGHTENING TORQUES Cylinder head tightening sequence Crankcase tightening sequence ...

Page 89: ...2 29 SPEC 1 Crankshaft 2 Main axle 3 Drive axle OIL FLOW DIAGRAMS ...

Page 90: ...2 30 SPEC 1 Oil nozzle 2 Main gallery bolt 3 Crankshaft OIL FLOW DIAGRAMS ...

Page 91: ...2 31 SPEC 1 Main axle 2 Drive axle 3 Oil delivery pipe OIL FLOW DIAGRAMS ...

Page 92: ...2 32 SPEC 1 Exhaust camshaft 2 Oil check bolt 3 Intake camshaft OIL FLOW DIAGRAMS ...

Page 94: ...2 34 SPEC 1 Crank pin 2 Crankshaft OIL FLOW DIAGRAMS ...

Page 97: ...2 37 SPEC 1 Main axle 2 Drive axle 3 Middle drive shaft OIL FLOW DIAGRAMS ...

Page 98: ...2 38 SPEC COOLING SYSTEM DIAGRAMS 1 Radiator COOLING SYSTEM DIAGRAMS ...

Page 99: ...2 39 SPEC 1 Water jacket joint 2 Oil cooler COOLING SYSTEM DIAGRAMS ...

Page 101: ...2 41 SPEC 1 Coolant reservoir 2 Radiator 3 Water pump COOLING SYSTEM DIAGRAMS ...

Page 107: ...2 47 SPEC CABLE ROUTING 1 Tail brake light lead ...

Page 196: ...3 80 CHK ADJ ADJUSTING THE HEADLIGHT BEAMS ...

Page 288: ...4 92 CHAS 3 Install bearing 1 to the swingarm Installed depth a 4 0 mm 0 16 in SWINGARM ...

Page 531: ...8 35 ELEC LIGHTING SYSTEM ...

Page 570: ......

Page 571: ...YAMAHA MOTOR CO LTD 2500 SHINGAI IWATA SHIZUOKA JAPAN PRINTED IN U S A ...