3 - 41

CHK

ADJ

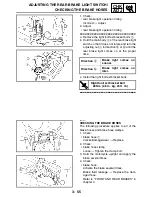

BLEEDING THE HYDRAULIC CLUTCH SYSTEM

NOTE:

@

• Be careful not to spill any clutch fluid or allow

the clutch master cylinder reservoir to over-

flow.

• When bleeding the hydraulic clutch system,

make sure there is always enough clutch

fluid before applying the clutch lever. Ignor-

ing this precaution could allow air to enter the

hydraulic clutch system, considerably length-

ening the bleeding procedure.

• If bleeding is difficult, it may be necessary to

let the clutch fluid settle for a few hours.

Repeat the bleeding procedure when the tiny

bubbles in the hose have disappeared.

1. Bleed:

• hydraulic clutch system

▼▼▼

▼

▼ ▼▼▼

▼

▼ ▼▼▼

▼

▼ ▼▼▼

▼

▼ ▼▼▼

▼

▼ ▼▼▼

▼

▼▼▼

a. Add the recommended clutch fluid to the

proper level.

b. Install the clutch master cylinder reservoir

diaphragm.

c. Connect a clear plastic hose

1

tightly to the

bleed screw

2

.

d. Place the other end of the hose into a con-

tainer.

e. Slowly squeeze the clutch lever several

times.

f. Fully squeeze the clutch lever without

releasing it.

g. Loosen the bleed screw.

This will release the tension and cause the

clutch lever to contact the handlebar grip.

h. Tighten the bleed screw and then release

the clutch lever.

i. Repeat steps (e) to (h) until all of the air

bubbles have disappeared from the clutch

fluid in the plastic hose.

j. Tighten the bleed screw to specification.

T

R

.

.

Bleed screw

6 Nm (0.6 m · kg, 4.3 ft · lb)

Summary of Contents for FJR1300

Page 1: ...LIT 11616 16 18 5JW 28197 10 FJR1300R FJR1300RC SERVICE MANUAL ...

Page 6: ......

Page 82: ...2 22 SPEC TIGHTENING TORQUES Cylinder head tightening sequence Crankcase tightening sequence ...

Page 89: ...2 29 SPEC 1 Crankshaft 2 Main axle 3 Drive axle OIL FLOW DIAGRAMS ...

Page 90: ...2 30 SPEC 1 Oil nozzle 2 Main gallery bolt 3 Crankshaft OIL FLOW DIAGRAMS ...

Page 91: ...2 31 SPEC 1 Main axle 2 Drive axle 3 Oil delivery pipe OIL FLOW DIAGRAMS ...

Page 92: ...2 32 SPEC 1 Exhaust camshaft 2 Oil check bolt 3 Intake camshaft OIL FLOW DIAGRAMS ...

Page 94: ...2 34 SPEC 1 Crank pin 2 Crankshaft OIL FLOW DIAGRAMS ...

Page 97: ...2 37 SPEC 1 Main axle 2 Drive axle 3 Middle drive shaft OIL FLOW DIAGRAMS ...

Page 98: ...2 38 SPEC COOLING SYSTEM DIAGRAMS 1 Radiator COOLING SYSTEM DIAGRAMS ...

Page 99: ...2 39 SPEC 1 Water jacket joint 2 Oil cooler COOLING SYSTEM DIAGRAMS ...

Page 101: ...2 41 SPEC 1 Coolant reservoir 2 Radiator 3 Water pump COOLING SYSTEM DIAGRAMS ...

Page 107: ...2 47 SPEC CABLE ROUTING 1 Tail brake light lead ...

Page 196: ...3 80 CHK ADJ ADJUSTING THE HEADLIGHT BEAMS ...

Page 288: ...4 92 CHAS 3 Install bearing 1 to the swingarm Installed depth a 4 0 mm 0 16 in SWINGARM ...

Page 531: ...8 35 ELEC LIGHTING SYSTEM ...

Page 570: ......

Page 571: ...YAMAHA MOTOR CO LTD 2500 SHINGAI IWATA SHIZUOKA JAPAN PRINTED IN U S A ...