7 - 8

FI

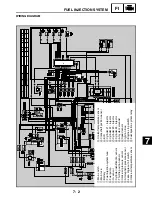

FUEL INJECTION SYSTEM

TROUBLESHOOTING

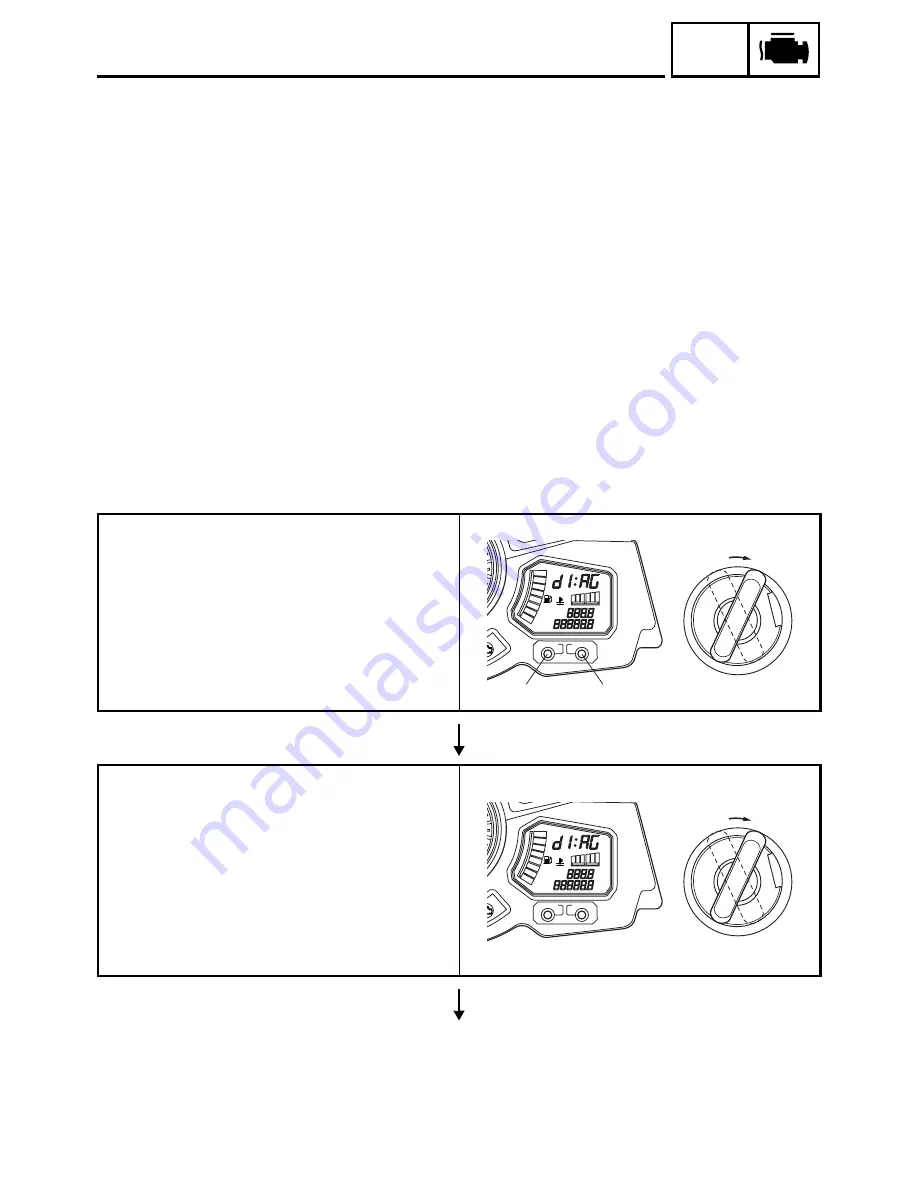

Diagnosis mode troubleshooting 1 (self-diagnostic malfunction detected)

By entering a diagnostic code in the ECU through the use of the “SELECT” and “RESET” buttons on

the multi-function meter, the sensor output values can be displayed and the actuators can be oper-

ated in accordance with the code that has been entered.

The technician determines whether or not the operation is normal by verifying the values displayed

on the multi-function meter or the operating conditions of the actuators. These modes can be used

to detect and check the problems that are otherwise difficult to detect in the diagnosis mode.

Basic operation procedure

Operation preparation

• Verify the self-diagnostic fault code number that is displayed on the meter.

• Based on the self-diagnostic fault code number, select the applicable sensor or actuator from the

diagnostic code table.

• If a diagnostic code is available, proceed with the operation procedure given below in order to

verify the operating conditions of the applicable sensor or actuator.

Operation procedure (make sure to turn “OFF” the main switch upon completing the operation prep-

aration)

Setting the ECU in the diagnosis mode

1. While keeping the “SELECT” and “RESET”

buttons pressed simultaneously, turn “ON”

the main switch (keep them pressed for 8

seconds or more).

* All indications on the meter disappear

except the clock and trip indications.

* Letters “dIAG” appear on the clock LCD.

Selecting the diagnosis mode

After “dIAG” appears as a result of pressing

the “SELECT” button, simultaneously press

the “SELECT” and “RESET” buttons for 2 sec-

onds or more to execute the selection.

220

240

260

280

200

180

Km/h

F

L

L

H

E

SELECT

RESET

TRIP

TRIP

km

mile

km

mile

000

OFF

ON

SELECT

RESET

Main switch

220

240

260

280

200

180

Km/h

F

L

L

H

E

SELECT

RESET

TRIP

TRIP

km

mile

km

mile

000

OFF

ON

Main switch

Summary of Contents for FJR1300

Page 1: ...LIT 11616 16 18 5JW 28197 10 FJR1300R FJR1300RC SERVICE MANUAL ...

Page 6: ......

Page 82: ...2 22 SPEC TIGHTENING TORQUES Cylinder head tightening sequence Crankcase tightening sequence ...

Page 89: ...2 29 SPEC 1 Crankshaft 2 Main axle 3 Drive axle OIL FLOW DIAGRAMS ...

Page 90: ...2 30 SPEC 1 Oil nozzle 2 Main gallery bolt 3 Crankshaft OIL FLOW DIAGRAMS ...

Page 91: ...2 31 SPEC 1 Main axle 2 Drive axle 3 Oil delivery pipe OIL FLOW DIAGRAMS ...

Page 92: ...2 32 SPEC 1 Exhaust camshaft 2 Oil check bolt 3 Intake camshaft OIL FLOW DIAGRAMS ...

Page 94: ...2 34 SPEC 1 Crank pin 2 Crankshaft OIL FLOW DIAGRAMS ...

Page 97: ...2 37 SPEC 1 Main axle 2 Drive axle 3 Middle drive shaft OIL FLOW DIAGRAMS ...

Page 98: ...2 38 SPEC COOLING SYSTEM DIAGRAMS 1 Radiator COOLING SYSTEM DIAGRAMS ...

Page 99: ...2 39 SPEC 1 Water jacket joint 2 Oil cooler COOLING SYSTEM DIAGRAMS ...

Page 101: ...2 41 SPEC 1 Coolant reservoir 2 Radiator 3 Water pump COOLING SYSTEM DIAGRAMS ...

Page 107: ...2 47 SPEC CABLE ROUTING 1 Tail brake light lead ...

Page 196: ...3 80 CHK ADJ ADJUSTING THE HEADLIGHT BEAMS ...

Page 288: ...4 92 CHAS 3 Install bearing 1 to the swingarm Installed depth a 4 0 mm 0 16 in SWINGARM ...

Page 531: ...8 35 ELEC LIGHTING SYSTEM ...

Page 570: ......

Page 571: ...YAMAHA MOTOR CO LTD 2500 SHINGAI IWATA SHIZUOKA JAPAN PRINTED IN U S A ...