8 - 10

–

+

ELEC

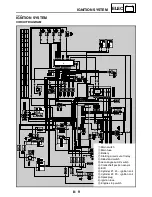

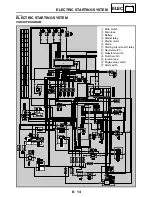

IGNITION SYSTEM

EAS00737

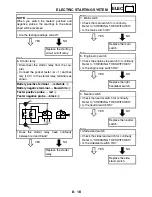

TROUBLESHOOTING

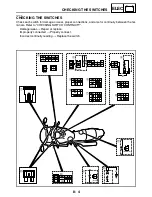

Procedure

Check:

1. main and ignition fuses

2. battery

3. spark plugs

4. ignition spark gap

5. spark plug cap resistance

6. ignition coil resistance

7. crankshaft position sensor resistance

8. main switch

9. engine stop switch

10.neutral switch

11.sidestand switch

12.starting circuit cut-off relay

13.wiring connections

(of the entire ignition system)

NOTE:

@

• Before troubleshooting, remove the following

part(s):

1) Seat

2) Fuel tank and T-bar

3) Side cowlings

4) Front cowling assembly

5) Air filter case

• Troubleshoot with the following special

tool(s).

EAS00738

YES

NO

EAS00739

YES

NO

EAS00741

YES

NO

The ignition system fails to operate (no

spark or intermittent spark).

Dynamic spark tester

YM-34487

Pocket tester

YU-03112

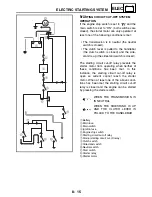

1. Main and ignition fuses

• Check the main and ignition fuses for conti-

nuity.

Refer to “CHECKING THE FUSES” in

chapter 3.

• Are the main and ignition fuses OK?

Replace the fuse(s).

2. Battery

• Check the condition of the battery.

Refer to “CHECKING AND CHARGING

THE BATTERY” in chapter 3.

Minimum open-circuit voltage

12.8 V or more at 20 °C (68 °F)

• Is the battery OK?

• Clean the battery

terminals.

• Recharge or

replace the battery.

3. Spark plugs

The following procedure applies to all of the

spark plugs.

• Check the condition of the spark plug.

• Check the spark plug type.

• Measure the spark plug gap.

Refer to “CHECKING THE SPARK PLUGS”

in chapter 3.

Standard spark plug

CR8E (NGK)

U24ESR-N (DENSO)

Spark plug gap

0.7 ~ 0.8 mm (0.028 ~ 0.031 in)

• Is the spark plug in good condition, is it of

the correct type, and is its gap within speci-

fication?

Re-gap or replace

the spark plug.

Summary of Contents for FJR1300

Page 1: ...LIT 11616 16 18 5JW 28197 10 FJR1300R FJR1300RC SERVICE MANUAL ...

Page 6: ......

Page 82: ...2 22 SPEC TIGHTENING TORQUES Cylinder head tightening sequence Crankcase tightening sequence ...

Page 89: ...2 29 SPEC 1 Crankshaft 2 Main axle 3 Drive axle OIL FLOW DIAGRAMS ...

Page 90: ...2 30 SPEC 1 Oil nozzle 2 Main gallery bolt 3 Crankshaft OIL FLOW DIAGRAMS ...

Page 91: ...2 31 SPEC 1 Main axle 2 Drive axle 3 Oil delivery pipe OIL FLOW DIAGRAMS ...

Page 92: ...2 32 SPEC 1 Exhaust camshaft 2 Oil check bolt 3 Intake camshaft OIL FLOW DIAGRAMS ...

Page 94: ...2 34 SPEC 1 Crank pin 2 Crankshaft OIL FLOW DIAGRAMS ...

Page 97: ...2 37 SPEC 1 Main axle 2 Drive axle 3 Middle drive shaft OIL FLOW DIAGRAMS ...

Page 98: ...2 38 SPEC COOLING SYSTEM DIAGRAMS 1 Radiator COOLING SYSTEM DIAGRAMS ...

Page 99: ...2 39 SPEC 1 Water jacket joint 2 Oil cooler COOLING SYSTEM DIAGRAMS ...

Page 101: ...2 41 SPEC 1 Coolant reservoir 2 Radiator 3 Water pump COOLING SYSTEM DIAGRAMS ...

Page 107: ...2 47 SPEC CABLE ROUTING 1 Tail brake light lead ...

Page 196: ...3 80 CHK ADJ ADJUSTING THE HEADLIGHT BEAMS ...

Page 288: ...4 92 CHAS 3 Install bearing 1 to the swingarm Installed depth a 4 0 mm 0 16 in SWINGARM ...

Page 531: ...8 35 ELEC LIGHTING SYSTEM ...

Page 570: ......

Page 571: ...YAMAHA MOTOR CO LTD 2500 SHINGAI IWATA SHIZUOKA JAPAN PRINTED IN U S A ...