Operations

115

© 2006 Vision Engraving Systems

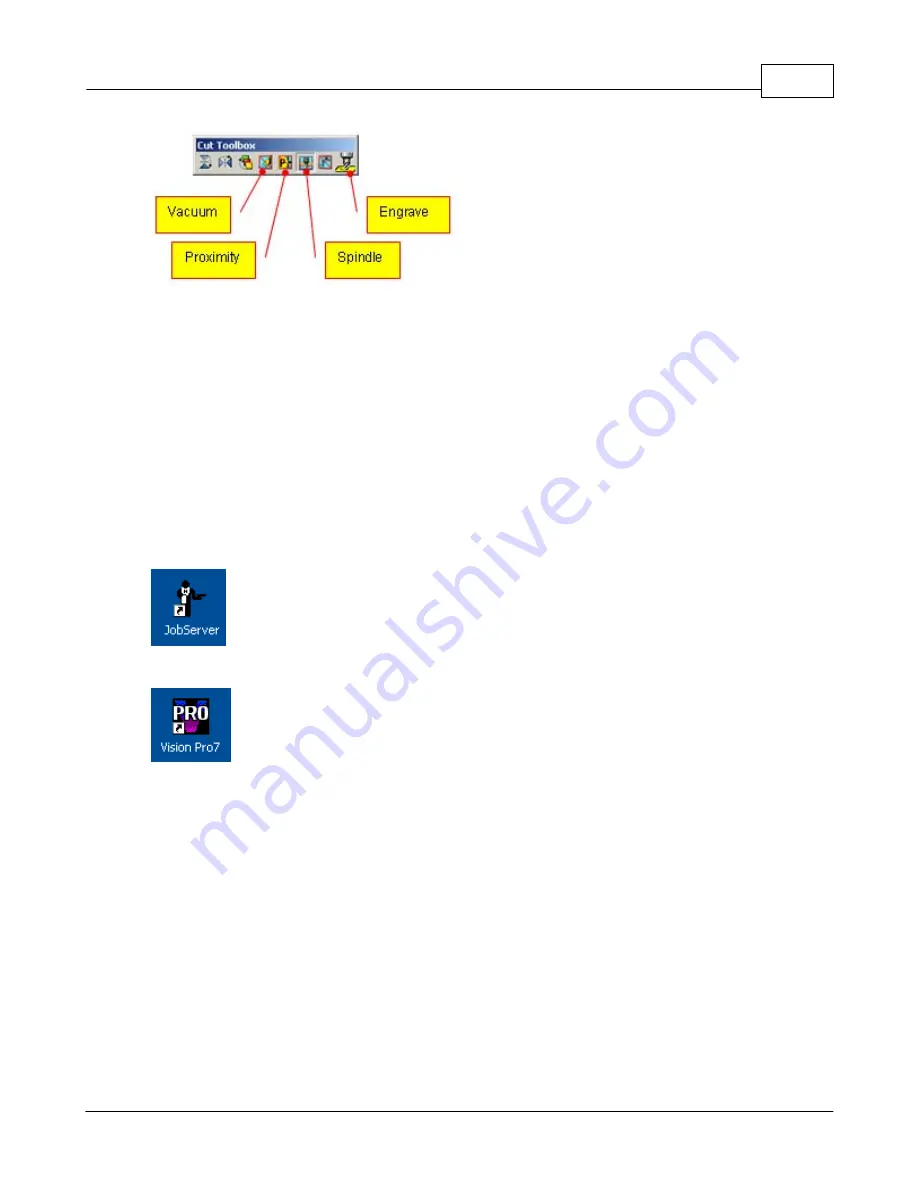

Click the Engrave icon. After a brief moment, the LCD screen on the hand help pendant will

display "Press Start to Go".

On the first luggage tag, it is recommended to do a "Dry Run" with the red pointer to ensure

the correct positioning of the text on the pen. Press the

Shift

button on the hand held

pendant and then press

Start

. The machine will run the job with the red pointer. You can

verify that the engraving will be in the correct position.

If it is in the correct position, you can now engrave the pen. Press the

Start

button. The

LCD will display "Press Start to Go". Press the

Start

button and the luggage tag will be

engraved.

Lesson 5 - Engraving Rings and Bracelets

Make sure the MaxPro machine is powered on, the Goto Home button has been pressed

and the Job Server program has been started by clicking on the Job Server icon on the

Windows desktop.

Start Vision Pro by clicking the Vision Pro icon from the desktop in Windows.

Hardware setup

Press the “Rotary Axis” button and the LCD will display a choice: “1 – Standard mode” and

“2 – Ring mode”. Enter the number “2” and press enter.

On the next screen enter either the outside or inside diameter of the ring depending on what

side will be engraved using the digital calipers provided. Press “Enter” to complete. After

pressing “Enter” the machine will move to the center of the vice automatically.

Press Set Surface and then press the Enter button.

Mounting the ring attachment

The ring attachment mounts on the gearbox side of the vice (left side). Before sliding the

ring attachment over the drive shaft, locate the three mounting holes. Align the set screws

on the ring attachment with these holes and slide it on. Secure the screws with the included

T-Handle wrench. Turn the ring attachment by pressing the left or right arrow keys to reach

all the screws.

Summary of Contents for MaxPro

Page 5: ...Chapter I ...

Page 11: ...Chapter II ...

Page 23: ...Configuration 19 2006 Vision Engraving Systems 3 Click on the IP Address tab ...

Page 60: ......

Page 61: ...Chapter III ...

Page 100: ...Vision MaxPro 96 2006 Vision Engraving Systems Mounting the item to be engraved ...

Page 179: ...Operations 175 2006 Vision Engraving Systems The Plot screen below will appear ...

Page 182: ......

Page 183: ...Chapter IV ...

Page 191: ...Chapter V ...

Page 202: ...Vision MaxPro 198 2006 Vision Engraving Systems W Windows 2000 15 Windows 98 18 Windows XP 12 ...

Page 203: ......