Operations

101

© 2006 Vision Engraving Systems

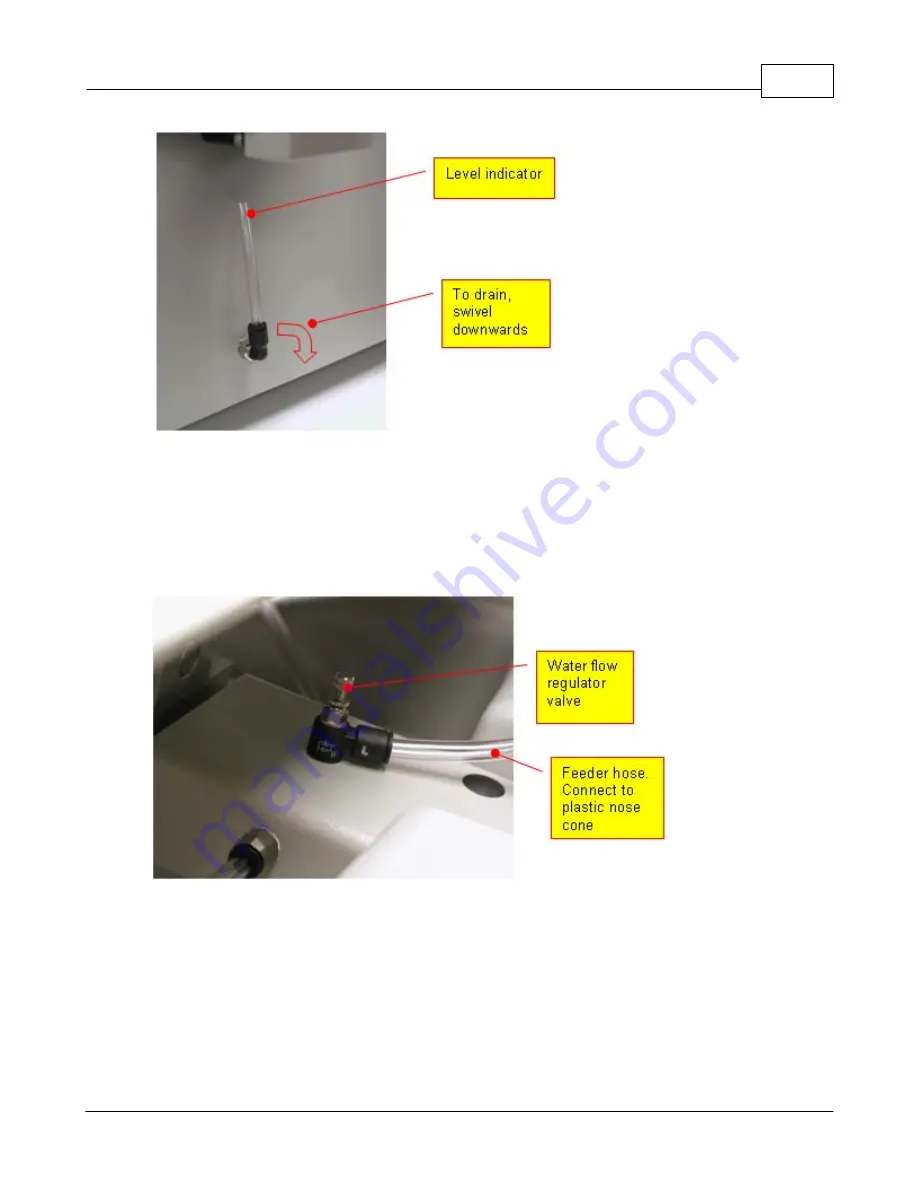

To drain the reservoir this indicator level can be swiveled downwards and the water will

drain.

Regulating the water flow

A minimal amount of water is needed during the engraving process. The flow can be

regulated by adjusting the valve located directly behind the vise. Clockwise reduces the flow

and counterclockwise increases the flow.

The pump is turned on automatically from the software when sending a job. Even though it

is simple enough to adjust the flow during the engraving process, the pump can be turned

on manually to check the flow. Press “Menu” and scroll until “Pump” is reached. Press

“Shift” and then “Enter” and the pump will turn on and adjust the flow to a trickle. Press

“Shift” and “Enter” again to shut it off.

Setting the surface

Press the “Jog Mode” key, this will allow the Z axis to be moved up or down, the green LED

will now be lit on the key. Using the down arrow key move the Z axis down until the diamond

Summary of Contents for MaxPro

Page 5: ...Chapter I ...

Page 11: ...Chapter II ...

Page 23: ...Configuration 19 2006 Vision Engraving Systems 3 Click on the IP Address tab ...

Page 60: ......

Page 61: ...Chapter III ...

Page 100: ...Vision MaxPro 96 2006 Vision Engraving Systems Mounting the item to be engraved ...

Page 179: ...Operations 175 2006 Vision Engraving Systems The Plot screen below will appear ...

Page 182: ......

Page 183: ...Chapter IV ...

Page 191: ...Chapter V ...

Page 202: ...Vision MaxPro 198 2006 Vision Engraving Systems W Windows 2000 15 Windows 98 18 Windows XP 12 ...

Page 203: ......