PCC-IV Instruction Manual (rev. 0.1)

Page 3-6

Section 3

-

Operation

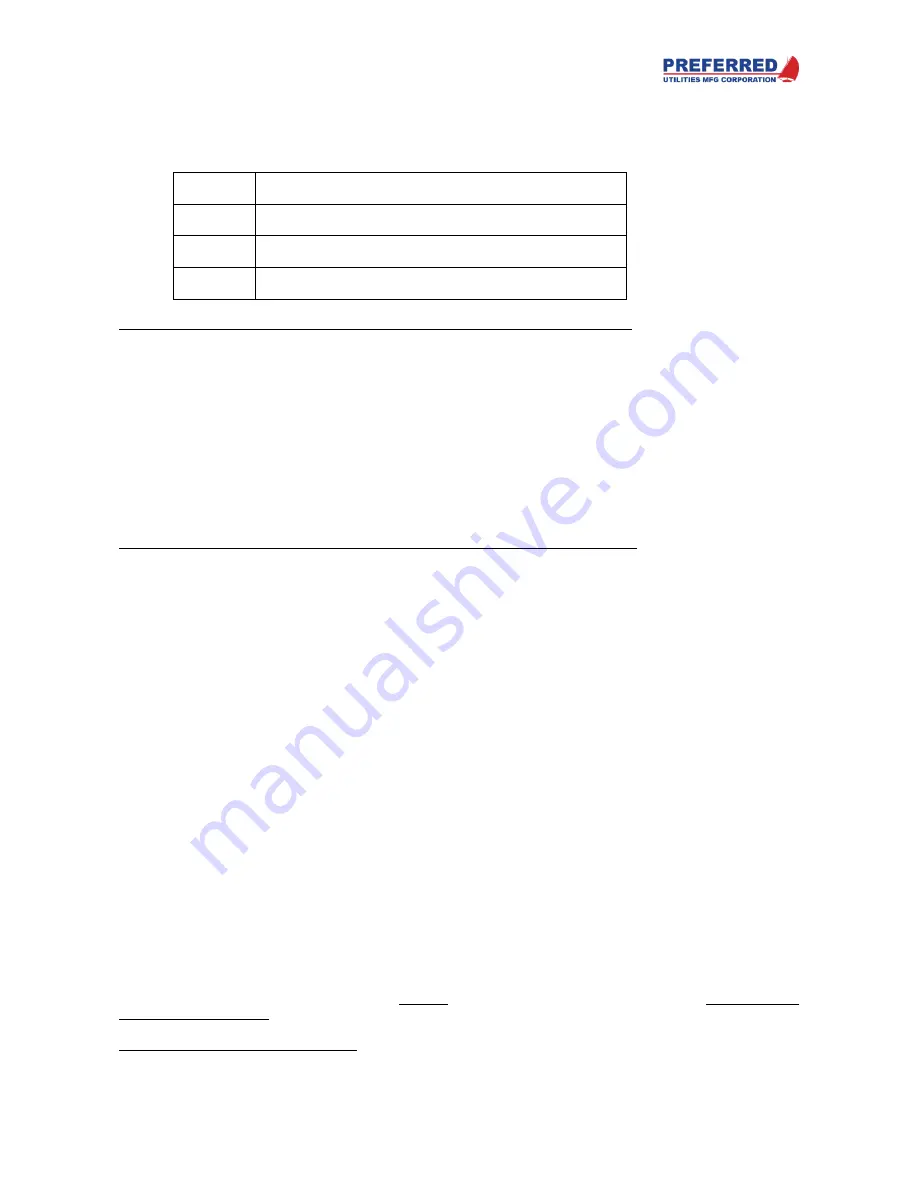

ALARM Light

The Alarm Light operates as follows:

Alarm

Light

Status

Blinking

One or more alarm messages have NOT been displayed.

Press, and hold,

ACK

to display the alarms screen.

ON

All alarm messages have been displayed.

1 or more alarm inputs are still in the alarm condition.

OFF

All alarm messages have been displayed.

No alarm inputs are in the alarm condition.

The operation of the

ALARM

light cannot be changed by the blockware designer. However, alarm(s) can be

disabled by blockware. Typically, this is done to prevent nuisance alarms when a process is shutdown.

ACK Soft-button and the Alarm Annunciator

The PCC-IV can monitor up to 10 different alarm conditions. When a new alarm condition occurs, the

ALARM

light

will start blinking. Optionally, the blockware designer can cause the PV bargraph and SP arrow to blink, and if

supplied, to activate a panel-mounted or remote alarm horn, bell, and/or light.

The first press and release of the

ACK

button silences an optional/external alarm horn or bell. If the

ALARM

light

continues to blink, then there are additional alarm messages that have not been silenced.

A long press of the

ACK

button (about 3 seconds) changes the display to the Alarm History screen. This displays

up to 10 active and unacknowledged alarms. Press the Back soft-button to return to the previous screen.

The operation of the

ACK

soft-button cannot be changed by the Blockware designer. However, alarm(s) can be

disabled by Blockware. Typically, this is done to prevent nuisance alarms when a process is shutdown.

Example:

A feedwater-controller monitors and has alarm channels for: Low Feedwater Supply Pressure, High Drum Level,

Low Drum Level, and Low-Low Drum Level. Assume that a boiler modulates up to maximum rate, but the feedwater

pump capacity is inadequate, the feedwater pressure drops, the drum level drops and the boiler eventually trips

due to low-low water level. After the boiler trips, the feedwater pressure returns to normal pressure. The displays

would respond as follows:

User Defined Soft-buttons

These four soft-buttons are configured by the blockware designer. The purpose and operation of each of these soft-

buttons is determined by the blockware designer. Review the documentation provided with the blockware for your

specific controller to determine the purpose of each soft-button. The blockware designer will label these buttons to

indicate the purpose of each soft-button.

User Defined Lights

These six lights are configured by the Blockware designer. The purpose and operation of each of these lights is

determined by the blockware designer. Review the documentation provide

d with your specific controller’s blockware

to determine the purpose of each light.

The four lights that are located to the lower-left of a soft-button are all controlled by blockware that is independent

of the operation of the soft-button itself. While it is very common for these four lights to be used to indicate when

the soft-button is ON, it is not unusual for some of these lights to be used as simple indicators that are not affected

by the operation of the mating soft-button.

Multiple Loops

PCC-IV can control more than one loop at the same time. The method used to accomplish this is selected by the

blockware d

esigner. Review the documentation provided with your specific controller’s blockware to determine the

requirements specific to your application. Two different loop-select methods are described below. Only one of the

two methods will be used.

LOOP Soft-button Loop Select Method: As an example, one PCC-IV can simultaneously control boiler firing rate

based on drum pressure (the first loop) and the feedwater control valve based on drum level and steam flow (the