162

7-2 Maintenance Details of Parts

WARNING

• Maintenance work must be conducted with the power to the laser marker

turned OFF, and the AC power cable disconnected. Doing so may cause

exposure to the laser beam or electrical shock.

• Do not insert your hands or objects to the exhaust port of each unit or the

gaps between units during the maintenance work. This may result in injuries,

electrical shock, or failure of the laser marker.

7-2-1 Protection glass of laser emission port

An f θ lens is mounted at the laser emission port of the head section. The f θ lens condenses laser irradiated from the

oscillator at the position of the work distance. On the lens surface, AR (anti-reflection) coating is applied in order to maintain

appropriate transmittance.

For LP-RF series, a protection glass is attached to the laser emission port (lens). It protects the lens from dirt or damage.

An antireflection coating is applied to the protection glass surface in order to maintain appropriate transmittance.

Do not remove the protection glass during operation.

Effect from deterioration

The surface of the laser emission port may become contaminated by the dust and smoke during the laser marking. Using

laser marker with the contaminated laser emission port may cause the lens to get burned in. This may also scratch the lens

surface, or even peel off the surface coating depending on how it is used or cleaned.

Operations under these conditions will degrade transmittance of laser, which may lead to deterioration in quality of marking

and processing.

Replacement interval

• Deterioration in quality of marking and processing (density reduction of the marking, incomplete processing) is observed.

• There is contamination or scratch that cannot be removed by cleaning.

Replacement method

Replace the protection glass of the laser emission port referring to “7-2-2 Replacement of the protection glass” (P.163).

If any damage of the laser emission port (fθ lens) is observed when the protection glass is removed, our service

representative handles the replacement. Contact our sales office.

Cleaning steps for protection glass of laser emission port (Daily maintenance)

In order to maintain stable marking quality, the protection glass of laser emission port needs to be cleaned regularly

according to the usage environment.

1.

Turn OFF the key switch of the controller, and disconnect the AC power cable.

2.

Clean the laser emission port with an air duster for optics, and wipe it lightly with

a soft cloth. If a contamination is severe, use a soft cloth immersed in ethanol to

wipe it.

ワㄐㄕㄊㄆ

• Do not wipe the protection glass of laser emission port strongly, or touch it with a

sharp pointed object. Laser marker might become faulty.

WARNING

• Never use an inflammable air duster. The laser beam may ignite the gas,

resulting in fire.

Soft cloth

Protection glass

ME-LPRF-SM-11

Summary of Contents for LP-RF Series

Page 17: ...1 Product Overview ME LPRF SM 11...

Page 34: ...2 Laser Marker Installation ME LPRF SM 11...

Page 57: ...3 Operation Method ME LPRF SM 11...

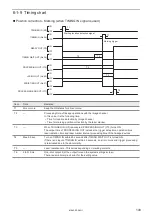

Page 81: ...4 External Control Using I O ME LPRF SM 11...

Page 126: ...5 External Control by Communication Commands ME LPRF SM 11...

Page 135: ...6 Link Control with External Devices ME LPRF SM 11...

Page 160: ...7 Maintenance ME LPRF SM 11...

Page 186: ...Troubleshooting ME LPRF SM 11...

Page 214: ...Index ME LPRF SM 11...

Page 216: ...216 USB 32 55 W Warning 205 ME LPRF SM 11...

Page 217: ......