Ottobock | 17

3R106, 3R106=KD, 3R106=ST, 3R106=HD

4.2 Combination possibilities

INFORMATION

In a prosthesis, all prosthetic components have to meet the patient‘s requirements regarding the

amputation level, body weight, activity level, environmental conditions and field of application.

4.3 Adjustments and final assembly

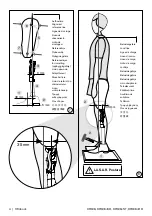

4.3.1 Socket fabrication 3R106=KD

4.3.1.1 Lamination prior to trial fitting

Take a piece of 623T3 Perlon Stockinette twice the length of the plaster model and pull half of

it over the isolated socket. Twist the other half of the stockinette on the distal end and reflect it

over the socket.

In order to absorb strong forces in the area of the modular knee joint, the socket must be gradu-

ally reinforced with 616G13 Fiberglass Stockinette. To do this, pull over the first layer to

2

/

3

of the

socket length, tie it off and then reflect it up to half of the socket length.

Put 2 layers of 616G12 Carbon-Fiber Cloth on the distal area so as to provide an underlying base

with a projecting brim of 3 cm around the 4G70 Adapter, which will be mounted later in the procedure.

Pull on two layers of 623T3 Perlon Stockinette.

The socket lamination is performed in two stages. In the first stage the socket is laminated up to

2

/

3

of its length with 617H19 Orthocryl Lamination Resin. In the second stage the proximal part

of the socket is laminated with 617H17 Orthocryl Flexible Resin.

Once the first casting has hardened, pull on 2 more layers of 623T3 Perlon Stockinette before

laminating the proximal part of the socket with 617H17 Orthocryl Flexible Resin.

4.3.1.2 Applying the lamination anchor

Prior to gluing, prepare the correctly adapted lamination anchor with the residual limb bedding.

To do so, fill the coupling opening with 636K8 Plastaband (Fig. 3). Clamp residual limb bedding

and joint into the alignment apparatus.

Attention!

Remove soft, flexible or porous materials from beneath the support surface of the lami

-

nation anchor.

Mix the putty exclusively from 617H21 Orthocryl Sealing Resin and

639A1 Talcum Powder. Then glue on the lamination anchor.

Secure with 627B2 Adhesive Tape for trial fitting. Test the stop function. If necessary, form the

required contact surface with putty. If need be, glue an extension stop made of Pedilin onto the

outer laminate.

4.3.1.3 Socket completion

Once the trial fitting has been completed, fasten the lamination anchor to the socket with truss

head screws (Fig. 1, (3)) and two-hole nuts (Fig. 1, (2)). Then laminate. Proceed with further re-

inforcement as follows: Two layers of 616G12 Carbon Fiber Cloth must be sandwiched between

two layers of 623T3 Perlon Stockinette. To achieve this, pull one layer of 623T3 Perlon Stockinette

over the whole socket and tie it circularly at the top. Apply two layers of 616G12 Carbon Fiber

Cloth over the arms of the 4G70 Adapter. Pull the remaining half of the 623T3 Perlon Stockinette

back over the carbon fiber layers. Gradually reinforce the socket again with 616G13 Fiberglass

Stockinette (as described in point 4.3.1.1

). As a final step, pull over 2 layers of Perlon Stockinette

623T3. Proceed with lamination as in the first casting.

Summary of Contents for 3R106

Page 3: ...Ottobock 3 3R106 3R106 KD 3R106 ST 3R106 HD 3 4 2 1 3 4 2 5 7 7a 6...

Page 133: ...Ottobock 133 3R106 3R106 KD 3R106 ST 3R106 HD 4 3 2 1 3R106 KD 3R106 ST 4 3 2 2 4 E 4 F F 4...

Page 152: ...152 Ottobock 3R106 3R106 KD 3R106 ST 3R106 HD 4 6 300 3 5 5 6 6 1 6 2 EU 2017 745 CE...

Page 159: ...Ottobock 159 3R106 3R106 KD 3R106 ST 3R106 HD 519L5 4 6 300 5 6 6 1 6 2 CE 2017 745 CE...

Page 160: ...160 Ottobock 3R106 3R106 KD 3R106 ST 3R106 HD...

Page 161: ...Ottobock 161 3R106 3R106 KD 3R106 ST 3R106 HD...