Ottobock | 15

3R106, 3R106=KD, 3R106=ST, 3R106=HD

Attention!

It is not allowed to loosen, shift, or replace the connection adapter!

For the prosthetic fitting of hip disarticulations, it is of utmost importance that the specially

adapted knee joint version 3R106=HD is used.

3 Technical data

Order number

3R106

3R106=KD

3R106=ST

3R106=HD

Proximal connection

Pyramid

adapter

Lamination

anchor

Thread

(M26x1.5)

Pyramid

adapter

Distal connection

Tube clamp ⌀ 30 mm

Knee flexion angle

170°

Weight

760 g

755 g

765 g

790 g

System height

162 mm

184 mm

180 mm

164 mm

Proximal system height up

to alignment reference point

-6 mm

16 mm

12 mm

-4 mm

Distal system height up to

alignment reference point

168 mm

Max. user weight

100 kg / 220 lbs

Mobility Grade

2 + 3

4 Handling

Use 2Z11=KIT

INFORMATION

: The connection area of the prosthetic knee joint can be protected against

scratches with the protective film of the 2Z11=KIT during alignment in the workshop and testing

in the trial fitting area.

•

Use the protective film as illustrated in the accompanying document for the 2Z11=KIT.

•

Remove the protective film before the patient leaves the fitting area.

4.1 Alignment

The three-dimensional arrangement of the prosthetic socket and the modular components affects

the static and dynamic functions of the prosthesis.

The advantages of the 3R160 Knee Joint can only be made optimal use of in case of a correct alignment.

The optimal residual limb position must be anticipated when positioning the socket connec-

tor.

Plumb lines in the frontal and sagittal planes (drawn from the hip joint’s center of rotation and

marked during plaster cast taking and trial fitting of the test socket) will facilitate correct position

-

ing of the lamination anchor or socket adapter.

To align the prosthesis please proceed in two steps:

1. First make the bench alignment using an alignment tool (such as 743L200 L.A.S.A.R. Assembly

or PRO.S.A. Assembly 743A200).

2. Then use 743L100 L.A.S.A.R. Posture for static alignment optimization.

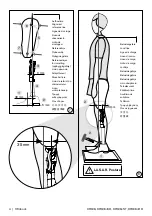

4.1.1 Bench alignment with alignment tool

(the following steps refer to Fig. 7)

Position the middle of the foot

30 mm anterior

to the alignment reference line.

Add 5 mm to the required heel height of the foot. Set correct outward rotation of the foot.

Summary of Contents for 3R106

Page 3: ...Ottobock 3 3R106 3R106 KD 3R106 ST 3R106 HD 3 4 2 1 3 4 2 5 7 7a 6...

Page 133: ...Ottobock 133 3R106 3R106 KD 3R106 ST 3R106 HD 4 3 2 1 3R106 KD 3R106 ST 4 3 2 2 4 E 4 F F 4...

Page 152: ...152 Ottobock 3R106 3R106 KD 3R106 ST 3R106 HD 4 6 300 3 5 5 6 6 1 6 2 EU 2017 745 CE...

Page 159: ...Ottobock 159 3R106 3R106 KD 3R106 ST 3R106 HD 519L5 4 6 300 5 6 6 1 6 2 CE 2017 745 CE...

Page 160: ...160 Ottobock 3R106 3R106 KD 3R106 ST 3R106 HD...

Page 161: ...Ottobock 161 3R106 3R106 KD 3R106 ST 3R106 HD...