Wheel System - Traction

121

Service Manual – SC1500

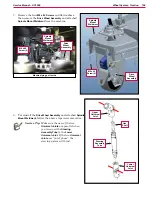

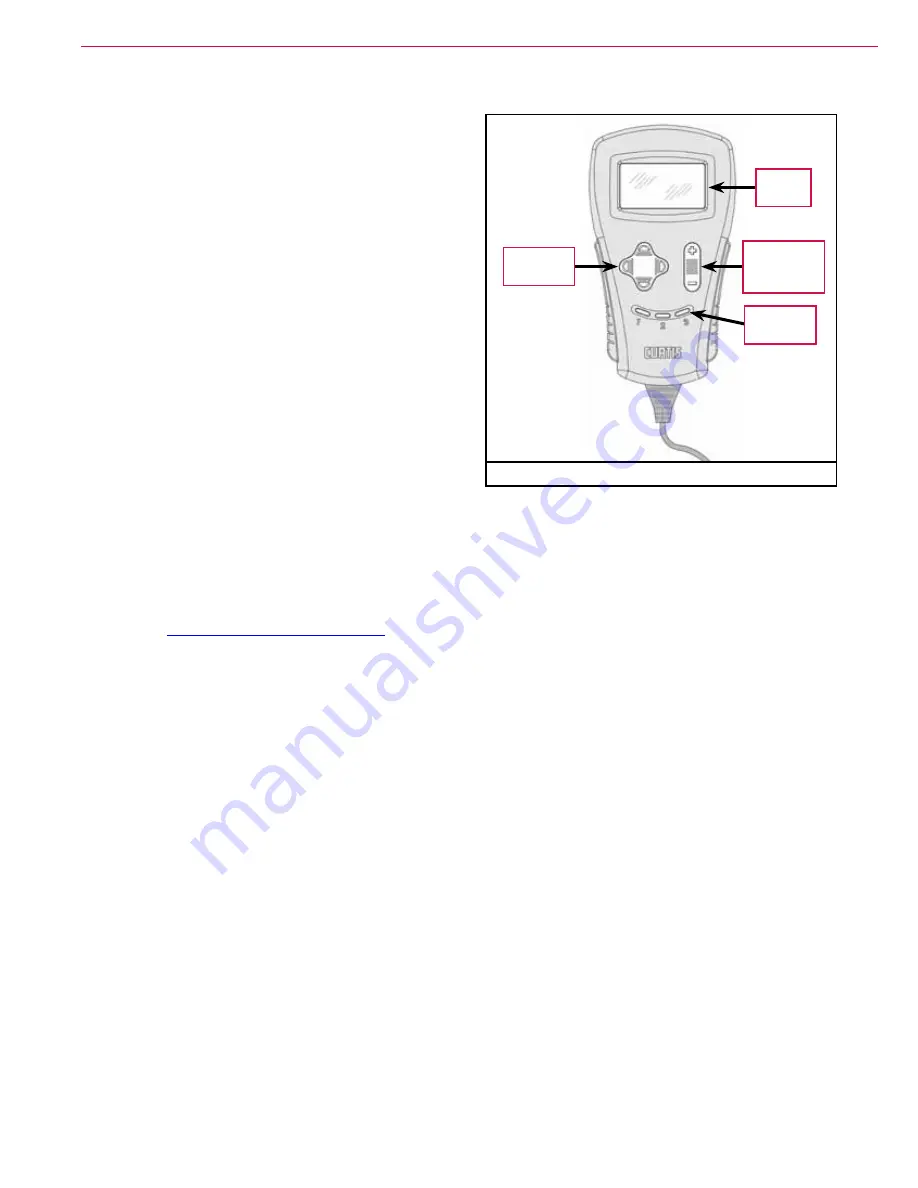

Diagnostics Method B - Curtis Programmer

Diagnostics Method B uses the optional hand-held

Curtis programmer model 1311. With a programmer,

diagnostics and troubleshooting are more direct than

with the Detergent On/Off Indicator LED alone. The

programmer presents complete diagnostic information

in plain language with no codes to decipher. The

LCD

Display

shows faults on the Diagnostic Menu and the

controller input/output status on the Test Menu.

•

Navigation Key

– used to move around through the

programmer menus.

•

Parameter Modification Key

– used to increase and

decrease values.

•

Bookmark Keys

– used for jumping back and forth

between fields.

The following five-step process is generally used

for diagnosing and troubleshooting an inoperative

machine:

1

Visually inspect the machine for obvious problems.

1

Diagnose the problem using the programmer.

1

Test the circuitry with the programmer.

1

Correct the problem.

1

Repeat the last three steps as necessary until the vehicle is operational.

Refer to the

on page 122 for suggestions covering a wide range of possible

faults.

Diagnostic History

You can use the handheld programmer to access the controller’s diagnostic history:

The programmer will read out all the faults that the controller has experienced since the last time the

diagnostic history file was cleared. The faults may be intermittent faults, faults caused by loose wires or

faults caused by Operator errors. Faults such as HPD or over-temperature may be caused by Operator

habits or by overloading.

After a problem has been diagnosed and corrected, it’s recommended that you clear the diagnostic history

file. This allows the controller to accumulate a new file of faults. By checking the new diagnostic history file

at a later date, you can readily determine whether the problem was indeed completely fixed.

Navigation

Key

LCD

Display

Parameter

Modification

Key

Bookmark

Keys

Curtis 1311 Handheld Programmer