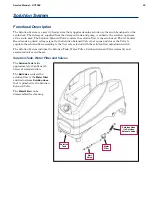

Solution System

100

Service Manual – SC1500

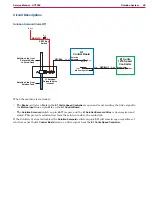

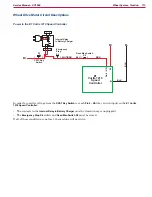

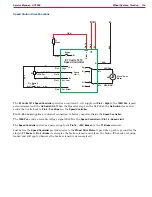

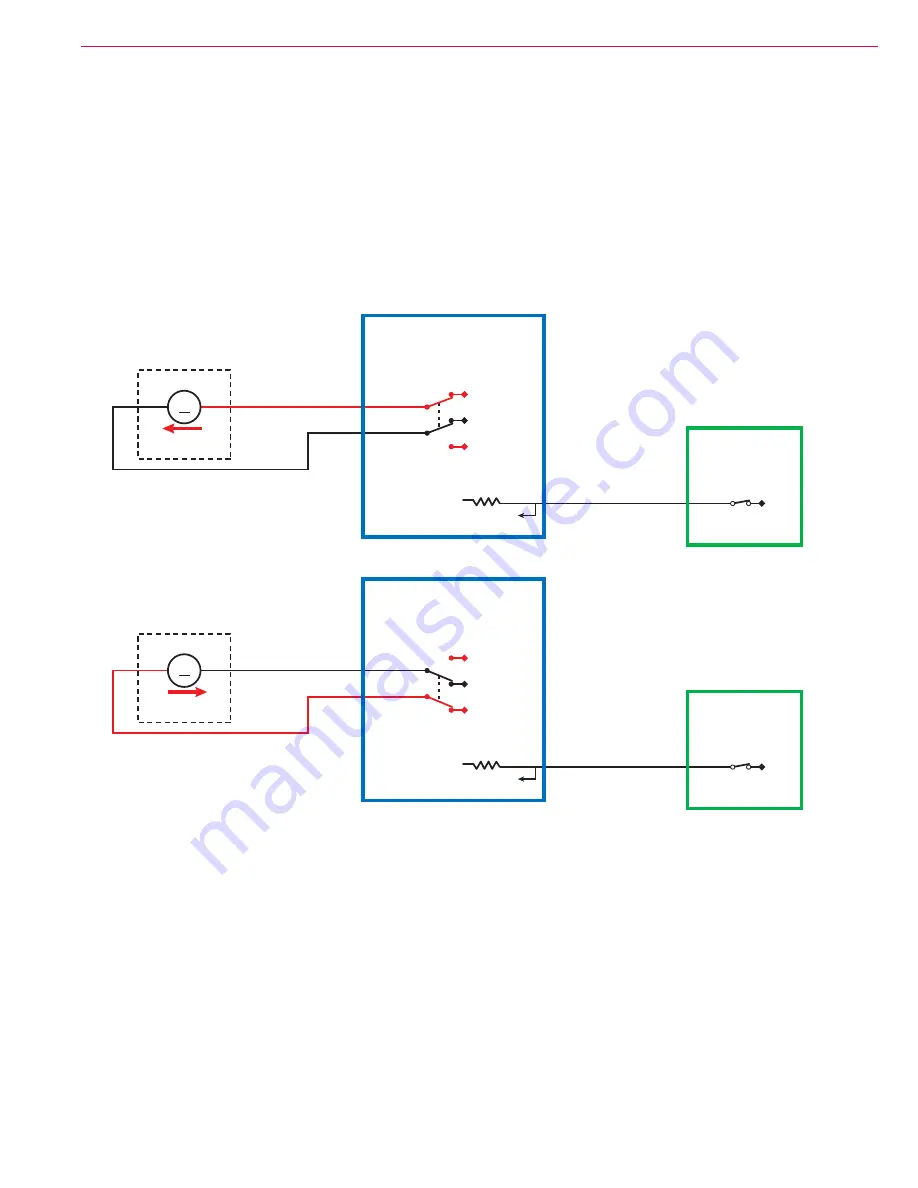

Detergent Pump On

The following conditions must be met before the

M2 Detergent Pump

can start:

• There can be no major faults active.

• The machine must not be in a low-voltage condition.

• The Scrub System must be enabled (the Solution On/Off Indicator is lighted).

• The Detergent System must be installed and enabled.

• The

S7 POS 1

limit switch on the scrub deck actuator must be closed to indicate that the scrub deck is

below the vacuum-only position.

• The

A1 Control Board

must receive a motion signal from the

E1 Curtis Speed Controller

Bat -

Pin 6

J3-6

24v

Pin 6

M2

-

+

M

J1-3 -

J1-1 +

Bat +

Bat -

Bat +

RED/YEL

BLU/GRA

RED/WHT

Detergent

Pump

Detergent

Pump

Detergent

Pump

Brake -

A1

Control Board

E1

Curtis 1210

Speed

Controller

Motion Input (0.1v)

Bat -

Pin 6

J3-6

24v

Pin 6

M2

-

+

M

J1-3 -

J1-1 +

Bat +

Bat -

Bat +

RED/YEL

BLU/GRA

RED/WHT

Detergent

Pump

Detergent

Pump

Detergent

Pump

Brake -

A1

Control Board

E1

Curtis 1210

Speed

Controller

Motion Input (0.1v)

When the Operator selects a drive direction and presses the go pedal:

• The

Brake-

switch on

Pin 6

in the

E1 Curtis Speed Controller

closes to ground. This drops the voltage on

the

Motion Input

line on pin

J3-6

from 24v down to nearly 0 volts to signal the

A1 Control Board

that the

machine is now in motion.

• The

Detergent Pump

switches on pins

J1-1

and

J1-3

to alternate the voltage polarity to the

M2 Detergent

Pump

. This moves the pump plunger and diaphragm in and out to deliver the detergent to the solution

line.

Note that the

A1 Control Board

varies the number of pump strokes per minute to control the detergent flow

rate according to deck type, and the solution flow rate and detergent ratio selected.