5

START-UP

38

OPTIWAVE 1010

www.krohne.com

10/2016 - 4003537403 - MA OPTIWAVE 1010 R03 en

5.3.5 Diagnosis window

Use this data to do a check of the device's condition (error messages etc.).

You can do one of these three procedures to open the Diagnosis window:

•

Open the window from the Start

Start

Start

Start window. Click on Start

Start

Start

Start in the DTM menu and then click on the

Diagnosis

Diagnosis

Diagnosis

Diagnosis button at the bottom of the Start

Start

Start

Start window.

•

Open the window from the main toolbar. Click on Device > Diagnosis

Device > Diagnosis

Device > Diagnosis

Device > Diagnosis.

•

Open the window from the Project

Project

Project

Project window. Right click on the device (OPTIWAVE 1010

OPTIWAVE 1010

OPTIWAVE 1010

OPTIWAVE 1010) in the

project list, then click on Diagnosis

Diagnosis

Diagnosis

Diagnosis.

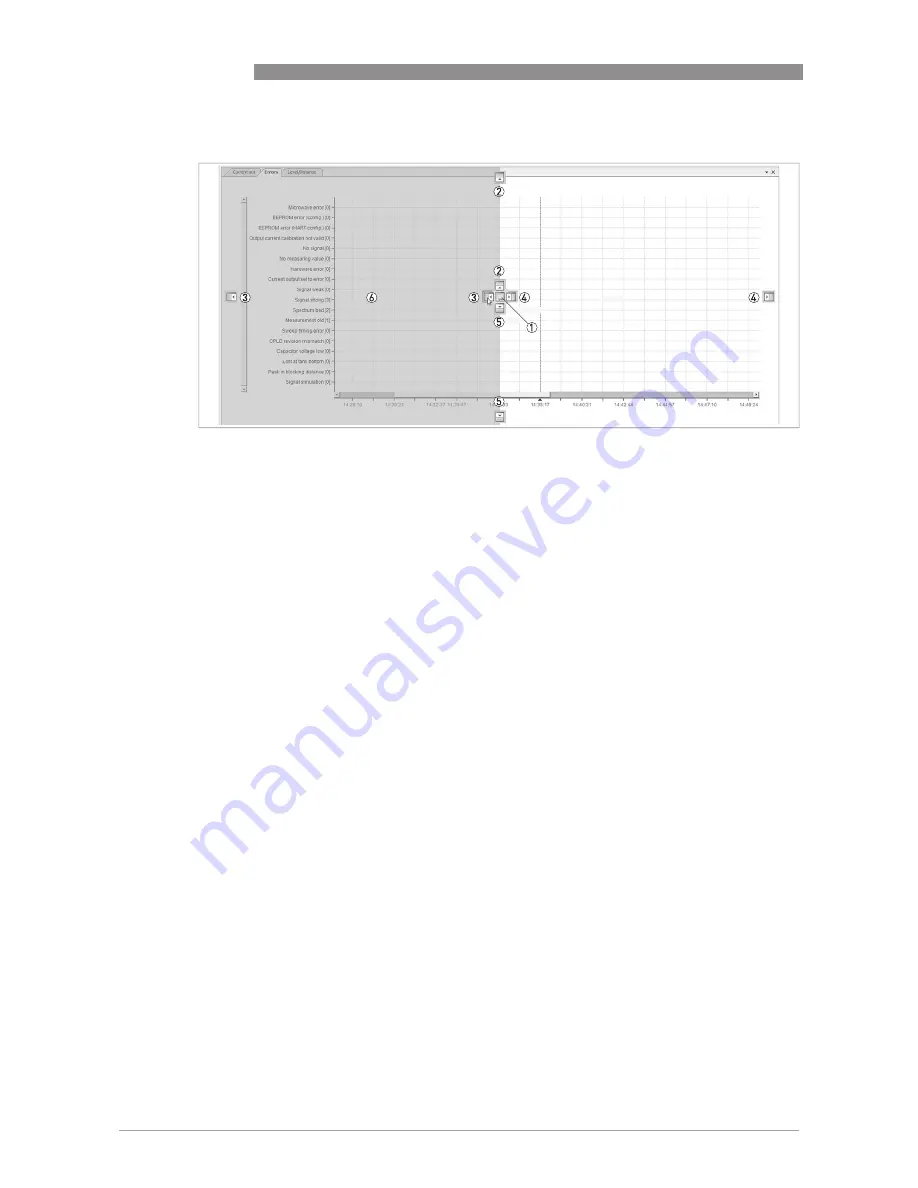

Figure 5-6: How to put two or more graphs on one tab

1

Graph position symbol: create another tab for this graph

2

Graph position symbol: move this graph to the top

3

Graph position symbol: move this graph to the left side

4

Graph position symbol: move this graph to the right side

5

Graph position symbol: move this graph to the bottom

6

In this example, the user clicks on the graph position symbol

3

and the graph is shown on the left side on the same tab