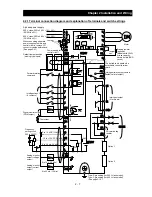

Chapter 2 Installation and Wiring

2 - 18

(4) Recommended cable gauges, wiring accessories, and crimp terminals

Note: For compliance with CE and UL standards, see the safety precautions concerning EMC and the

compliance with UL and cUL standards under Safety Instructions.

The table below lists the specifications of cables, crimp terminals, and terminal screw tightening torques for

reference.

Motor

output

(kW)

Applicable inverter

model

Gauge of power

line cable (mm

2

)

(Terminals: R, S,

T, U, V, W, P, PD,

and N)

Grounding

cable (mm

2

)

External braking

resistor across

terminals P and

RB (mm

2

)

Size of

terminal

screw

Crimp

terminal

Tightening

torque (N-m)

Applicable device

Earth-leakage

breaker (ELB)

Magnetic

contactor

(MC)

200 V

cl

ass

11 L700-110LFF

14

14

14

M5 R14-5

2.4(MAX4.0)

RX100

(75A)

HK50

15 L700-150LFF

22

22

14

M6 22-6

4.0(MAX4.4)

RX100 (100A)

H65

18.5 L700-185LFF

30

22

22

M6 38-6

4.5(MAX4.9)

RX100 (100A)

H80

22 L700-220LFF

38

30

22

M6 38-6

4.5(MAX4.9) RX225B (150A)

H100

30 L700-300LFF 60

(22

×

2) 30

30 M8

R60-8

8.1(MAX8.8) RX225B (200A)

H125

37 L700-370LFF 100

(38

×

2) 38

―

M8

100-8

8.1(MAX8.8) RX225B (225A)

H150

45 L700-450LFF 100

(38

×

2) 38

―

M8

100-8

8.1(MAX20) RX225B (225A)

H200

55 L700-550LFF 150

(60

×

2) 60

―

M8

150-8

8.1(MAX20) RX400B (350A)

H250

75 L700-750LFF 150 (60

×

2) 80

―

M10

R150-10 19.5(MAX22) RX400B (350A)

H300

400 V

cl

ass

11 L700-110HFF

5.5

5.5

5.5

M5

R5.5-5

2.4(MAX4.0)

EX50C (30A)

HK35

15 L700-150HFF

8

8

5.5

M6 R8-6

4.0(MAX4.4)

EX60B (60A)

HK35

18.5 L700-185HFF

14

14

8

M6 R14-6

4.5(MAX4.9)

EX60B (60A)

HK50

22 L700-220HFF

14

14

8

M6 R14-6

4.5(MAX4.9)

RX100 (75A)

HK50

30 L700-300HFF

22

22

14

M6 R22-6

4.5(MAX4.9)

RX100 (100A)

H65

37 L700-370HFF

38

22

―

M6

38-6

4.5(MAX4.9)

RX100 (100A)

H80

45 L700-450HFF

38

22

―

M8

R38-8

8.1(MAX20) RX225B (150A)

H100

55 L700-550HFF

60

30

―

M8

R60-8

8.1(MAX20)

RX255B

(175A)

H125

75 L700-750HFF 100(38X2)

38

―

M8

100-8

8.1(MAX20)

RX225B(225A)

H150

90 L700-900HFF 100(38X2)

38

―

M10

R100-10 20.0(MAX22)

RX225B(225A)

H200

110 L700-1100HFF 150(60X2)

60

―

M10

R150-10 20.0(MAX35)

RX400B(350A)

H250

132 L700-1320HFF

80X2 80

―

M10

80-10

20.0(MAX35) RX400B(350A) H300

160 L700-1600HFF 100X2

80

―

M10

R100-10 20.0(MAX35)

RX400B(350A)

H400

Note: Cable gauges indicate those of HIV cables (maximum heat resistance: 75°C).

*1

)

Please use the round type crimp terminals ( for the UL standard) suitable for the use electric wire when you

connect the electric wire with the main circuit terminal stand. Please put on pressure to the crimp terminals l with a

crimp tool that the terminal stand maker recommends.

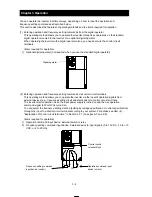

(5) Connecting the control circuit to a power supply separately from the main circuit

If the protective circuit of the inverter operates to open the magnetic contactor in the input power

supply circuit, the inverter control circuit power is lost, and the alarm signal cannot be retained.

To retain the alarm signal, connect control circuit terminals R0 and T0 to a power supply.

In details, connect the control circuit power supply terminals R0 and T0 to the primary side of the

magnetic contactor as shown below.

(Connection method)

Power-receiving specifications

200 V class model:

200 to 240 V (+10%, -15%)

(50/60 Hz ±5%),(282 to 339 VDC)

400 V class model:

380 to 480 V (+10%, -15%)

(50/60 Hz ±5%),(537 to 678 VDC)

②

Remove the J51 connector.

①

Remove the connected cables.

③

Connect the control circuit power

supply cables to the control

circuit power supply terminal

block.

J51

Summary of Contents for L700 Series

Page 16: ... Memo ...

Page 20: ... Memo ...

Page 22: ... Memo ...

Page 46: ... Memo ...

Page 60: ... Memo ...

Page 62: ... Memo ...

Page 212: ... Memo ...

Page 222: ... Memo ...

Page 224: ... Memo ...

Page 232: ... Memo ...

Page 238: ...Chapter 7 Specifications 7 6 L700 750 LFF 6 Cable hole φ41 ...

Page 239: ...Chapter 7 Specifications 7 7 L700 900 to 1100HFF L700 1320 to 1600HFF ...

Page 240: ... Memo ...

Page 242: ... Memo ...

Page 258: ... Memo ...