REV0 10.02.15

-H9-6-

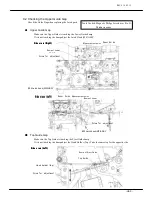

9.5 Adjusting the Imprinting Gap

Check the Imprinting Gap when replacing the Imprinting Head

#17 Imprinting head ASSY

#108 DC Motor(NMB)

Bearing

#107

Imprinting head

Replacing the Imprinting Head ASSY

①

Put the Imprinting Head ASSY on the LL

washer faced heads and tighten 2 bind-head screws.

②

Make sure the Roller and the Bearing is

touching each other. Check whether the center of

the Imprinting Head ASSY should be leaning

towards the left, and loosen 2 bind-head screws. If

the two are not touching each other, use the long

hole on the Imprinting Head ASSY to adjust it.

After, attach the LL washer head on the Imprinting

Head ASSY.

③

Use the thickness gauge and measure the gap

between the Imprinting Head and the Roller. It

should be 0.2~0.35mm. If the gap is outside that

boundary, adjust the knob on the Imprinting Head;

●

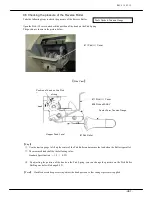

Replacing the Imprinting Head

①

Check whether the center of the Imprinting

Head ASSY should be leaning towards the left, and

loosen 2 bind-head screws.

②

Use the thickness gauge and measure the gap

between the Imprinting Head and the Roller. It

should be 0.2~0.35mm. If the gap is out of

specification, adjust the Bind-head screw on the

Imprinting Head;

Platen Roller

LL

washer(2)

Bind-head Screw(2)

Adjust with long hole

Screw for adjustment

2 bind-head Screws

Tools Needed: Magnetic Philips Screwdriver (No.2),

Thickness gauge

Summary of Contents for HT-4139-28

Page 1: ...HT 4139 28 48 Scanner Maintenance Manual ...

Page 2: ......

Page 11: ... H2 5 2 5 Block Diagram ...

Page 22: ...REV0 10 02 15 H3 10 Lens Mirror Motor Mirror No 1 Mirror No 3 Mirror No 2 ...

Page 35: ...REV0 10 02 15 H7 2 ...

Page 63: ...REV0 2010 02 15 H7 30 ...

Page 89: ...REV0 10 02 15 H8 26 ...