REV0

10.02.15

-H3-2-

3.2 Consumables

Outlined below are the consumables that must be replaced during Routine Maintenance

Consumable List

Order

P a r t

R e p l a c e m e n t

P e r i o d

R e f e r e n c e

Action

Page

1

Pick Roller

2

Separator Roller

3

Reverse Roller

1.0 Million Pages

(*1)

or 1 year.

Whichever comes

first

The Customers

replace the

Consumables

Instruction

Manual

2.7

(Replacing

the Roller)

4

Fluorescent Lamp

900 Hours

Replace when warning sign appears

*2

8.2.3

、

8.2.4

5

Imprinting Head

ASSY

5.4 Million Pages

(*1)

6 Numbers/ Page

8.3.9

6

Separator Clutch

Separator Roller Gear

8.2.1

7

Oiles Drymet

Axle bearing of the Separator Roller

(4)

8.2.1

8

Oiles Brush

Axle bearing of the Pick Roller (2)

8.2.1

9

Gear (S-P)

Pick Unit Gears

8.3.39

10

Washer 1

Axle bearing of the Separator Roller

(2)

8.2.1

11

Washer 2

Axle bearing of the Separator Roller

(2)

8.2.1

12

Gear (Reverse 3)

Axle bearing on the Reverse Roller

8.2.2

13

Pick Gear

Gear on the Pick Roller

(Including for Model HT-F4139-94)

8.2.1

14

Pick Drive Gear 2

Gear on the Pick Drive

8.2.2

15

Reverse ASSY

Including the Torque Limiter

8.3.16

16

Cover Sheet ASSY

17

Cover Glass ASSY

2.0 Million Pages

(*1)

Maintenance

Personnel

replaces the

Consumables.

8.3.14

Ribbon Cassette for

Imprinting

When Needed

Red: S-4181 (30,000 Letters)*1

Black: C-4181 (30,000 Letters)*1

Ribbon Cassette for

Imprinting (Tank)

When Needed

Red: S-4181T(2.0 Million Letters)*3

Black: C-4181T(2.0 Million Letters)*3

18

Dummy: Y-4181(1.0 Million Pages)*1

The Customers

replace the

Consumables

Instruction

Manual

2.4.2

(Replacing

the Roller)

Refer to next page

Summary of Contents for HT-4139-28

Page 1: ...HT 4139 28 48 Scanner Maintenance Manual ...

Page 2: ......

Page 11: ... H2 5 2 5 Block Diagram ...

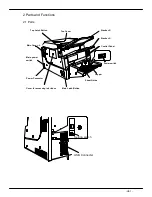

Page 22: ...REV0 10 02 15 H3 10 Lens Mirror Motor Mirror No 1 Mirror No 3 Mirror No 2 ...

Page 35: ...REV0 10 02 15 H7 2 ...

Page 63: ...REV0 2010 02 15 H7 30 ...

Page 89: ...REV0 10 02 15 H8 26 ...