100

Chapter

5

•

•

•

•

•

•

•

Make sure that nothing is draped over the scale/vessel or the load cell, such as a hose,

electrical cord, tubes, or other objects.

•

Check to see that nothing comes in contact with the scale/vessel other than service wires

and piping that have been properly mounted with flexible connectors.

Electrical Check Procedures

Check to see that there is power to the Weight Controller.

•

If there is power to the controller the front panel display should be lit.

•

If the display appears with a value the unit is ready for calibration.

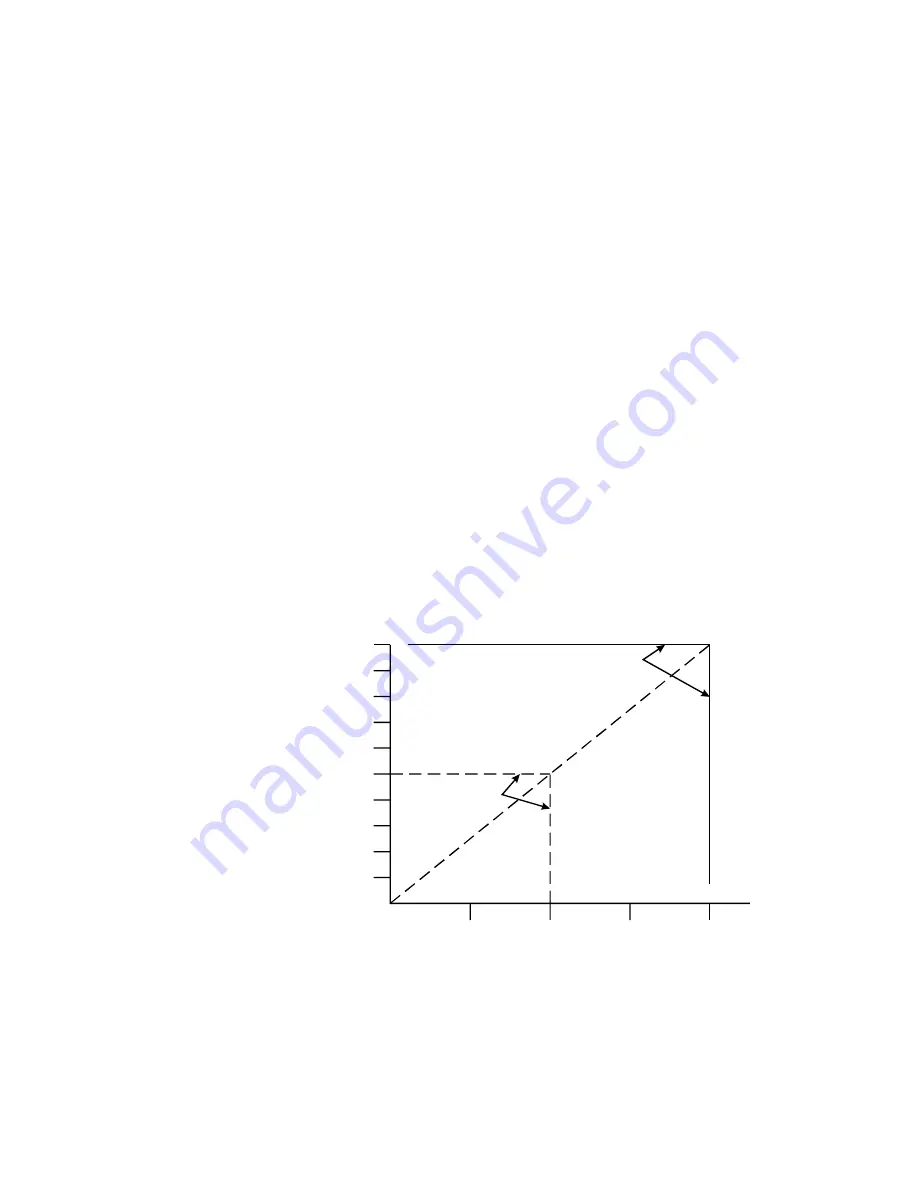

The 4050 supplies 5 VDC excitation to as many as eight 350 ohm load cells/points, and the

expected output from each load cell/point depends on the mV/V rating of the load cell/point

and weight.

Typical Load Cell/Point Input/Output Measurements (EXC & SIG outputs)

•

A 2 mV/V load cell/point will respond with a maximum of 10 mVDC at full

weight capacity where the system includes the weight of the vessel and the weight

of the product as measured by the load cell/point.

•

If the load cell/point weight capacity is rated at 1000 pounds, the load cell/point

output will be10 mVDC at 1000 pounds, 7.5 mVDC at 750 pounds, 5 mVDC at

500 pounds and so on.

•

A zero reference point will vary from system to system depending on the “Dead

Load” (weight of the vessel and appurtenances only, with no product loaded) of

the vessel. The example below uses a dead load of 500 lbs.

250

500

750

1000

10

9

8

7

6

5

4

3

2

1

WEIGHT IN POUNDS

M

IL

LIV

O

LTS D

C

DEAD LOAD 500#

ZERO REFERENCE POINT

MAXIMUM LOAD CAPACITY

Summary of Contents for HI 4050

Page 18: ...8 Chapter 1 ...

Page 24: ...14 Chapter 2 ...

Page 116: ...108 Chapter 5 ...

Page 184: ...4 Appendix A ...

Page 191: ......