16

7

6-2-2 Trouble shooting (Thread break)

Trouble Factor Cause of trouble and measure

Page

Thread break

Environment

4

. Is there something that produce steam, wasted cotton, dust around.

the embroidery machine?

5-1 Keep the embroidery machine off those things.

(2-5)

5. Does thread go out of control by taking wind from outside or heater etc.?

(2-5)

6-1 Keep the embroidery machine off such wind.

6-2 Move the embroidery machine to proper place.

Pattern

1. Does thread break occur repeatedly at same place in design?

1-1 Check pattern to modify punching.

2. Is it too narrow between stitches?

2-1 Check pattern to modify punching.

2-2 Setting of [OPTION] menu. (Stitch sweep)

(14-4)

3. Too many empty stitches?

3-1 Make [OPTION] setting. (this setting doesn't read empty stitches)

(14-4)

Others 1. Using spray paste (adhesive material)

1-1 Clean around rotary hook.

(23-2)

1-2 Replace or clean needle.

3-1-2

1-3 Use this paste at a given place and never use in front or back of

the embroidery machine.

( ) ---Reference instruction book

Summary of Contents for HCS2-1201-30

Page 1: ...Maintenance Manual for Embroidery Machine HCS2 1201 30 Version 2 3 HappyJapan Inc...

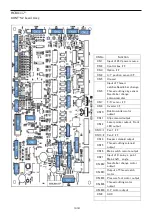

Page 154: ...153 5 1 1 Electrical connection diagram except for Rev A...

Page 155: ...154 5 1 1 Electrical connection diagram except for Rev A...

Page 156: ...155 5 1 2 List of electrical connection diagrams except for Rev A...

Page 157: ...156 5 1 3 Electrical connection diagram for Rev A...

Page 158: ...157 5 1 3 Electrical connection diagram for Rev A...

Page 159: ...158 5 1 4 List of electrical connection diagrams for Rev A...

Page 160: ...159 5 2 1 Connection of inverter 100V Inverter set...

Page 161: ...160 5 2 2 Connection of inverter 200V Inverter set...

Page 165: ...160c HCD8116 TP switch board ass y 6 5 265 2 1 6 7 257...