3 - 38

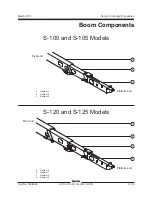

S-100 • S-105 • S-120 • S-125

Part No. 1268494

March 2017

Section 3 • Repair Procedures

28 Remove the retaining fasteners from the limit

switch cover on the side of the number 0 boom

tube at the platform end of the boom.

29 Carefully remove the cover with proximity and

limit switches from the number 0 boom tube at

the platform end of the boom.

Tip-over hazard. Failure to install

the correct proximity and/or limit

switches in the correct location will

result in the machine tipping over,

resulting in death or serious injury.

30 Tag and disconnect the wiring connectors from

the proximity and limit switches at the ground

controls side of the number 0 boom tube at the

platform end of the boom. Do not remove the

proximity or limit switches.

31 Remove the retaining fasteners from each black

plastic boom tube cover at the platform end of

the machine. Remove the covers.

32 Remove and label the top and side wear pads

of the number 3 boom tube at the pivot end

of the boom. Do not remove the bottom wear

pads.

Note: Pay careful attention to the location and

amount of shims used with each wear pad.

33 Remove and label the top and side wear pads

from the number 2 boom tube at the platform

end of the boom. Do not remove the bottom

wear pads.

Note: Pay careful attention to the location and

amount of shims used with each wear pad.

BOOM COMPONENTS

34 Attach a lifting strap from an overhead crane to

the number 3 boom tube at the platform end of

the boom.

35 Support and slide the number 3 boom tube out

of the number 2 boom tube. When the number

3 boom tube is approximately halfway removed,

remove the bottom wear pads from the number

2 boom tube at the platform end of the boom.

Crushing hazard. The number

3 boom tube may become

unbalanced and fall when it is

removed from the number 2 boom

tube if it is not properly supported

and attached to the overhead

crane.

Note: During removal, the overhead crane strap

will need to be adjusted for proper balancing.

36 Remove and label the top and side wear pads

from the number 2 boom tube at the pivot end

of the boom. Do not remove the bottom wear

pads.

Note: Pay careful attention to the location and

amount of shims used with each wear pad.

37 Remove and label the top and side wear pads

from the number 1 boom tube at the platform

end of the boom. Do not remove the bottom

wear pads.

Note: Pay careful attention to the location and

amount of shims used with each wear pad.

38 Attach a lifting strap from an overhead crane to

the number 2 boom tube at the platform end of

the boom.

Summary of Contents for S-100

Page 246: ...March 2017 Section 6 Schematics 6 22 Safety Circuit Schematic 6 21 ...

Page 259: ...Section 6 Schematics March 2017 6 35 6 36 Electrical Schematic Generator Options ...

Page 262: ...March 2017 Section 6 Schematics 6 38 6 37 Electrical Schematic 12 kW Generator welder option ...

Page 264: ...March 2017 Section 6 Schematics 6 40 Perkins 1104D 44T Engine Electrical Schematic 6 39 ...

Page 265: ...Section 6 Schematics March 2017 6 41 Perkins 854F 34T Engine Electrical Schematic 6 42 ...

Page 268: ...March 2017 Section 6 Schematics 6 44 Perkins 854F 34T Engine Harness 6 45 ...

Page 269: ...Section 6 Schematics March 2017 6 45 Deutz TD2011L04i Engine Electrical Schematic 6 46 ...

Page 271: ...Section 6 Schematics March 2017 6 47 Deutz TD2 9 Engine Electrical Schematic 6 48 ...

Page 274: ...March 2017 Section 6 Schematics 6 50 Deutz TD2 9 Engine Electrical Harness 6 51 ...

Page 276: ...March 2017 Section 6 Schematics 6 52 6 53 Hydraulic Schematic 12 kW Generator welder option ...