3 - 2

S-100 • S-105 • S-120 • S-125

Part No. 1268494

March 2017

Section 3 • Repair Procedures

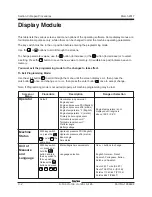

Display Module

This table lists the various screens and menu options of the operating software. Some display menus are

for informational purpose only, while others can be changed to alter the machine operating parameters.

The key switch must be in the

off

position before entering the programming mode.

Use the or

buttons to scroll through the screens.

To change parameter values, use the button (to increase) or the

button (to decrease) or to select

a setting. Press the

button to save the new value to memory. An audible beep will indicate a save to

memory.

You must exit the programming mode for the changes to take effect.

To Exit Programming Mode:

Use the scroll button to scroll through the menu until the screen displays

exit

,

then press the

plus button once, and change

no

to

yes

, then press the enter button

once to accept change.

Note: If Programming mode is not exited properly, all machine programming may be lost.

Screen or

Menu

Procedure

Description

Range or Selection

Hour meter (on power up)

Engine speed

Engine oil pressure PSI (English)

Engine oil pressure kPa (metric)

Engine temperature °F (English)

Engine temperature °C (metric)

Primary boom angle sensor

Turntable level sensor X°

Turntable level sensor Y°

Platform angle

Battery voltage

Operator

Machine

Status

Unit of

Measure

and

Language

Engine temperature is not

displayed until engine is

above 100°F / 38°C

Default

With key switch

on

, press the

and at

the

same time.

Hydraulic pressure PSI (English)

Hydraulic pressure kPa (metric)

Boom angle

Axle status

Metric/English measurements

Language selection

Use +/- buttons to change

English, German, French,

Spanish, Portuguese, Italian,

Dutch and Swedish.

Deutz 2.9L Turbo (D2.9T)

Deutz TD2011L0.4i (DL04i)

Perkins 1104D-44T (P1104)

Perkins 854F (P854T)

With key switch

off

, press and

hold the

button and turn

the key switch to

the

on

position.

Release the

button and press

Summary of Contents for S-100

Page 246: ...March 2017 Section 6 Schematics 6 22 Safety Circuit Schematic 6 21 ...

Page 259: ...Section 6 Schematics March 2017 6 35 6 36 Electrical Schematic Generator Options ...

Page 262: ...March 2017 Section 6 Schematics 6 38 6 37 Electrical Schematic 12 kW Generator welder option ...

Page 264: ...March 2017 Section 6 Schematics 6 40 Perkins 1104D 44T Engine Electrical Schematic 6 39 ...

Page 265: ...Section 6 Schematics March 2017 6 41 Perkins 854F 34T Engine Electrical Schematic 6 42 ...

Page 268: ...March 2017 Section 6 Schematics 6 44 Perkins 854F 34T Engine Harness 6 45 ...

Page 269: ...Section 6 Schematics March 2017 6 45 Deutz TD2011L04i Engine Electrical Schematic 6 46 ...

Page 271: ...Section 6 Schematics March 2017 6 47 Deutz TD2 9 Engine Electrical Schematic 6 48 ...

Page 274: ...March 2017 Section 6 Schematics 6 50 Deutz TD2 9 Engine Electrical Harness 6 51 ...

Page 276: ...March 2017 Section 6 Schematics 6 52 6 53 Hydraulic Schematic 12 kW Generator welder option ...