Part No. 1268494

S-100 • S-105 • S-120 • S-125

3 - 127

March 2017

Section 3 • Repair Procedures

FUEL AND HYDRAULIC TANKS

11-2

Hydraulic Tank

The primary functions of the hydraulic tank are to

cool, clean and deaerate the hydraulic fluid during

operation. It utilizes internal suction strainers for

the pump supply lines and has an external return

line filter with a filter condition indicator.

How to Remove the

Hydraulic Tank

Component damage hazard. The

work area and surfaces where

this procedure will be performed

must be clean and free of debris

that could get into the hydraulic

system.

Note: When removing a hose assembly or fitting,

the O-ring on the fitting and/or hose end must be

replaced and then torqued to specification during

installation.

Refer to Specifications,

Hydraulic Hose and Fitting

Torque Specifications.

1 Remove the ground controls side turntable

cover. See 5-1,

How to Remove a Hinged

Turntable Cover.

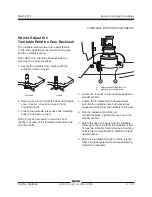

2 Close the two hydraulic shutoff valves located

at the hydraulic tank.

Component damage hazard. Be

sure that the hydraulic tank shutoff

valves are in the

open

position

before priming the pump. The

engine must not be started with

the hydraulic tank shutoff valves in

the

closed

position or component

damage will occur. If the hydraulic

tank shutoff valves are closed,

remove the key from the key

switch and tag the machine to

inform personnel of the condition.

3 Remove the drain plug from the hydraulic

tank and allow all of the oil from the tank to

drain into a suitable container. See capacity

specifications.

open closed

Summary of Contents for S-100

Page 246: ...March 2017 Section 6 Schematics 6 22 Safety Circuit Schematic 6 21 ...

Page 259: ...Section 6 Schematics March 2017 6 35 6 36 Electrical Schematic Generator Options ...

Page 262: ...March 2017 Section 6 Schematics 6 38 6 37 Electrical Schematic 12 kW Generator welder option ...

Page 264: ...March 2017 Section 6 Schematics 6 40 Perkins 1104D 44T Engine Electrical Schematic 6 39 ...

Page 265: ...Section 6 Schematics March 2017 6 41 Perkins 854F 34T Engine Electrical Schematic 6 42 ...

Page 268: ...March 2017 Section 6 Schematics 6 44 Perkins 854F 34T Engine Harness 6 45 ...

Page 269: ...Section 6 Schematics March 2017 6 45 Deutz TD2011L04i Engine Electrical Schematic 6 46 ...

Page 271: ...Section 6 Schematics March 2017 6 47 Deutz TD2 9 Engine Electrical Schematic 6 48 ...

Page 274: ...March 2017 Section 6 Schematics 6 50 Deutz TD2 9 Engine Electrical Harness 6 51 ...

Page 276: ...March 2017 Section 6 Schematics 6 52 6 53 Hydraulic Schematic 12 kW Generator welder option ...