Part No. 1268494

S-100 • S-105 • S-120 • S-125

3 - 113

March 2017

Section 3 • Repair Procedures

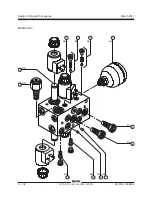

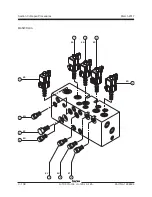

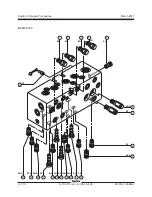

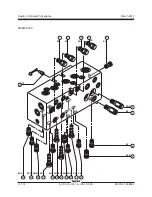

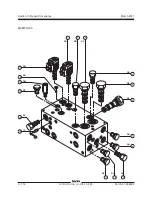

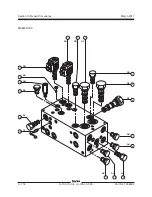

MANIFOLDS

10-17

Valve Adjustments - Steer and

Axle Extend/Retract Manifold

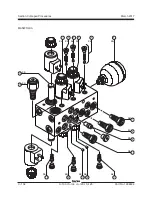

How to Adjust the Steer and Axle

Retract Relief Valve

Note: Perform this procedure with the axles

retracted and the boom in the stowed position.

1 Connect a 0 to 5000 psi / 0 to 345 bar pressure

gauge to the test port on the steer and axle

extend/retract manifold.

2 Start the engine from the platform controls.

3 Position the machine so that the left front wheel

is against an immoveable object such as a

curb.

4 Press down the foot switch and activate the

steer function. Steer the wheel into the curb

and hold. Observe the pressure reading on

the pressure gauge. Refer to Specifications,

Hydraulic Component Specifications.

5 Turn the engine off. Use a wrench to hold the

relief valve and remove the cap (item EZ).

6 Adjust the internal hex socket. Turn it clockwise

to increase the pressure or counterclockwise to

decrease the pressure. Install the relief valve

cap.

Tip-over hazard. Do not adjust

the relief valve higher than

specified.

7 Repeat steps 2 through 6 to confirm relief valve

pressure.

How to Adjust the Axle Extend

Relief Valve

Note: Perform this procedure with the axles

retracted, the boom in the stowed position and the

machine on a paved surface.

1 Connect a 0 to 5000 psi / 0 to 345 bar pressure

gauge to the test port on the steer and axle

extend/retract manifold.

2 Start the engine from the platform controls.

3 Press down the foot switch and push the axle

extend button. Observe the pressure reading

on the pressure gauge. Refer to Specifications,

Hydraulic Specifications.

4 Turn the engine off. Use a wrench to hold the

relief valve and remove the cap (item EQQ).

5 Adjust the internal hex socket. Turn it clockwise

to increase the pressure or counterclockwise to

decrease the pressure. Install the relief valve

cap.

Tip-over hazard. Do not adjust

the relief valve higher than

specified.

6 Repeat steps 2 through 5 to confirm relief valve

pressure.

Summary of Contents for S-100

Page 246: ...March 2017 Section 6 Schematics 6 22 Safety Circuit Schematic 6 21 ...

Page 259: ...Section 6 Schematics March 2017 6 35 6 36 Electrical Schematic Generator Options ...

Page 262: ...March 2017 Section 6 Schematics 6 38 6 37 Electrical Schematic 12 kW Generator welder option ...

Page 264: ...March 2017 Section 6 Schematics 6 40 Perkins 1104D 44T Engine Electrical Schematic 6 39 ...

Page 265: ...Section 6 Schematics March 2017 6 41 Perkins 854F 34T Engine Electrical Schematic 6 42 ...

Page 268: ...March 2017 Section 6 Schematics 6 44 Perkins 854F 34T Engine Harness 6 45 ...

Page 269: ...Section 6 Schematics March 2017 6 45 Deutz TD2011L04i Engine Electrical Schematic 6 46 ...

Page 271: ...Section 6 Schematics March 2017 6 47 Deutz TD2 9 Engine Electrical Schematic 6 48 ...

Page 274: ...March 2017 Section 6 Schematics 6 50 Deutz TD2 9 Engine Electrical Harness 6 51 ...

Page 276: ...March 2017 Section 6 Schematics 6 52 6 53 Hydraulic Schematic 12 kW Generator welder option ...