Part No. 1268494

S-100 • S-105 • S-120 • S-125

3 - 13

March 2017

Section 3 • Repair Procedures

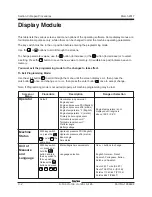

How to Set the Function

Thresholds and Function Speeds

Note: Before the threshold and default function

speeds can be set, the boom function proportional

valve coil defaults must be set first.

See

How to Reset a Proportional Valve Coil

Default.

Note: If a boom function proportional valve coil

has not been replaced and just want to reset the

function speed to original factory settings, begin

with step 10.

1 Start the engine from the platform controls.

2 Press down the foot switch.

Note: Be sure the engine rpm is set to foot switch

activated high idle.

Function threshold:

3 Select a joystick controlled function that needs

to have the threshold set.

4 Slowly move the joystick off center in either

direction just until the machine function starts

to move, then move the joystick very slowly

towards the neutral or center position just

before the machine function stops.

Do not let go of the joystick.

5 While holding the joystick in position, press the

engine start button

at the platform controls

to set the joystick controller threshold.

6 Slowly move the joystick off center in the

opposite direction just until the machine

function starts to move, then move the joystick

very slowly towards the neutral or center

position just before the machine function stops.

Do not let go of the joystick.

PLATFORM CONTROLS

REV B

How to Reset a Proportional

Valve Coil Default

(software version 2.00)

Note: Software version 2.00 requires the use of

Web GPI to perform this procedure.

Refer to Diagnostic Code

, Software

.

Note: This procedure only needs to be performed

if a proportional valve has been replaced.

Note: After the valve coil defaults have been set,

each machine function threshold and default

function speed must be set. See

How to Set the

Function Thresholds and Default Function Speeds.

1 Open Web GPI and connect to the TCON.

2 Select the valve screen of the proportional

valve you want to reset.

Note: Choices are: Propel (drive) valve reset;

Boom up/down valve reset; Boom extend/retract

valve reset; or TT rotate valve reset.

3 Press "set Defaults" and enter the level

2 password (obtained from field service

personnel).

4 Enter "0" (zero) into the threshold boxes.

5 Press "send" and enter the level 2 password

(obtained from field service personnel).

6 Disconnect from the TCON and proceed with

calibration.

Summary of Contents for S-100

Page 246: ...March 2017 Section 6 Schematics 6 22 Safety Circuit Schematic 6 21 ...

Page 259: ...Section 6 Schematics March 2017 6 35 6 36 Electrical Schematic Generator Options ...

Page 262: ...March 2017 Section 6 Schematics 6 38 6 37 Electrical Schematic 12 kW Generator welder option ...

Page 264: ...March 2017 Section 6 Schematics 6 40 Perkins 1104D 44T Engine Electrical Schematic 6 39 ...

Page 265: ...Section 6 Schematics March 2017 6 41 Perkins 854F 34T Engine Electrical Schematic 6 42 ...

Page 268: ...March 2017 Section 6 Schematics 6 44 Perkins 854F 34T Engine Harness 6 45 ...

Page 269: ...Section 6 Schematics March 2017 6 45 Deutz TD2011L04i Engine Electrical Schematic 6 46 ...

Page 271: ...Section 6 Schematics March 2017 6 47 Deutz TD2 9 Engine Electrical Schematic 6 48 ...

Page 274: ...March 2017 Section 6 Schematics 6 50 Deutz TD2 9 Engine Electrical Harness 6 51 ...

Page 276: ...March 2017 Section 6 Schematics 6 52 6 53 Hydraulic Schematic 12 kW Generator welder option ...