3 - 124

S-100 • S-105 • S-120 • S-125

Part No. 1268494

March 2017

Section 3 • Repair Procedures

Valve Coil Resistance

Specification

Note: The following coil resistance specifications

are at an ambient temperature of 68°F / 20°C. As

valve coil resistance is sensitive to changes in

air temperature, the coil resistance will typically

increase or decrease by 4% for each 18°F / 20°C

that your air temperature increases or decreases

from 68°F / 20°C.

Description

Specification

Solenoid valve, 2 position 3 way, 12V DC

9

Ω

(schematic item DA, DO, FB, FC)

Solenoid valve, 3 position 4 way, 12V DC

9.8

Ω

(schematic item EA, EB, EC, ED)

(before serial number 292)

Solenoid valve, 3 position 4 way, 12V DC

8.8

Ω

(schematic item EA, EB, EC, ED)

(after serial number 291)

Proportional solenoid valve, 12V DC

5.4

Ω

(schematic item FG, BG, GD, GH)

Proportional solenoid valve, 12V DC

5

Ω

(schematic item FB, FF, BB, BF)

3 position 4 way D03 valve, 12V DC

4.6

Ω

(schematic item FD, BD)

Solenoid Valve, 2 position 3 way, 12V DC

4.6

Ω

(schematic item FQ, FR, BQ, BR)

Solenoid Valve, 2 position 2 way, 12V DC

7.2

Ω

(schematic item BN, BO)

Solenoid valve, 3 position 4 way 12V

7.2

Ω

(schematic items ES, FC, BC)

(before serial number 292)

Solenoid valve, 3 position 4 way 12V

7.1

Ω

(schematic items ES)

(after serial number 291)

Solenoid valve, 2 position 3 way 12V

7.2

Ω

(schematic items AA)

How to Test a Coil Diode

Genie incorporates spike suppressing diodes in

all of its directional valve coils except proportional

valves and those coils with a metal case. Properly

functioning coil diodes protect the electrical circuit

by suppressing voltage spikes. Voltage spikes

naturally occur within a function circuit following

the interruption of electrical current to a coil. Faulty

diodes can fail to protect the electrical system,

resulting in a tripped circuit breaker or component

damage.

Electrocution/burn hazard. Contact

with electrically charged circuits

could result in death or serious

injury. Remove all rings, watches

and other jewelry.

1 Test the coil for resistance. Refer to,

How to

Test a Coil.

2 Connect a 10

Ω

resistor to the negative terminal

of a known good 9V DC battery. Connect the

other end of the resistor to a terminal on the

coil.

Note: The battery should read 9V DC or more

when measured across the terminals.

9V

BATTERY

10

RESISTOR

AMMETER

COIL

+

-

+

-

d

a

b

b

c

c

a multimeter

b

9V DC battery

c 10

Ω

resistor

d coil

Note: Dotted lines in illustration indicate a

reversed connection as specified in

step 6

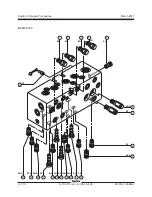

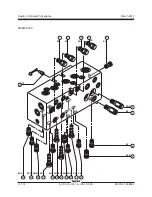

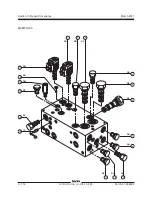

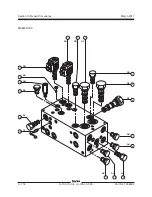

MANIFOLDS

Summary of Contents for S-100

Page 246: ...March 2017 Section 6 Schematics 6 22 Safety Circuit Schematic 6 21 ...

Page 259: ...Section 6 Schematics March 2017 6 35 6 36 Electrical Schematic Generator Options ...

Page 262: ...March 2017 Section 6 Schematics 6 38 6 37 Electrical Schematic 12 kW Generator welder option ...

Page 264: ...March 2017 Section 6 Schematics 6 40 Perkins 1104D 44T Engine Electrical Schematic 6 39 ...

Page 265: ...Section 6 Schematics March 2017 6 41 Perkins 854F 34T Engine Electrical Schematic 6 42 ...

Page 268: ...March 2017 Section 6 Schematics 6 44 Perkins 854F 34T Engine Harness 6 45 ...

Page 269: ...Section 6 Schematics March 2017 6 45 Deutz TD2011L04i Engine Electrical Schematic 6 46 ...

Page 271: ...Section 6 Schematics March 2017 6 47 Deutz TD2 9 Engine Electrical Schematic 6 48 ...

Page 274: ...March 2017 Section 6 Schematics 6 50 Deutz TD2 9 Engine Electrical Harness 6 51 ...

Page 276: ...March 2017 Section 6 Schematics 6 52 6 53 Hydraulic Schematic 12 kW Generator welder option ...