81

RTAA-IOM-3

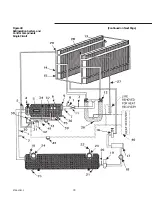

Figure 41

(Continued from Previous Page)

1 Schrader valve

2 Suction temperature sensor*

3 Manufacturing process tube

4 Suction service valve (optional)

5 Motor winding thermostat*

6 Discharge temperature sensor

7 Pressure relief valve (450 psi)

8 High pressure cutout (405 psi)*

9 Discharge check valve

10 Evaporator waterside vent

11 Discharge line shutoff valve

12 Oil separator in/out cap

13 Saturated condensing temperature

sensor*

14 Condenser header

15 Subcooler header

16 Liquid line shutoff valve

17 25 micron filter/drier

18 Liquid line sight glass

19 Electronic expansion valve*

20 Saturated evaporator temperature

sensor*

21 Evaporator waterside drain

22 Leaving water temperature sensor*

23 Leaving water connection

24 Entering water connection

25 Entering water temperature sensor*

26 Drain with Schrader valve

27 Oil line

28 Entering oil, cooler header

29 Leaving oil cooler header

30 Schrader valve with stem depressor

31 Oil line shutoff valve

32 5 micron oil filter

33 Master solenoid valve*

34 Oil line to load/unload slide valve

solenoids

35 Injection oil check valve

36 Heater

37 Slide valve solenoids and orifices*

38 Oil flow differential pressure switch*

39 Compressor Drain Plug

40 Domestic water heater (optional)

41 Oil line thermostat (option,

Domestic Water Heater)

42 Oil line bypass solenoid valve

(option, Domestic Water Heater)

*UCM Input/Output Control

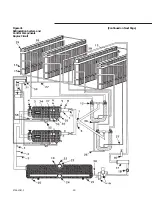

Figure 42

Typical RTAA Compressor

REFRIGERATION SYSTEM AND CONTROL COMPONENTS

Содержание RTAA-130

Страница 2: ... American Standard Inc 1991 ...

Страница 8: ...8 RTAA IOM 3 ...

Страница 13: ...13 RTAA IOM 3 Figure 3 Typical RTAA Packaged Unit 240 400 Tons Control Panel Evaporator Outlet Inlet ...

Страница 24: ...24 RTAA IOM 3 ...

Страница 26: ...26 RTAA IOM 3 Figure 9 Dimensions and Clearances for RTAA Packaged Unit 130 to 200 Ton RTAA SU 1000E ...

Страница 27: ...27 RTAA IOM 3 Figure 10 Dimensions and Clearances for RTAA Packaged Unit 240 300 Ton RTAA SU 1001C ...

Страница 28: ...28 RTAA IOM 3 Figure 11 Dimensions and Clearances for RTAA Packaged Unit 340 to 400 Ton RTAA SU 1002C ...

Страница 38: ...38 RTAA IOM 3 RTAA SA 2002C Figure 19 Spring Isolator Placement for Typical RTAA Packaged Unit 240 400 Tons ...

Страница 46: ...46 RTAA IOM 3 Figure 24 Typical Domestic Water Heater Piping Figure 25 Typical Domestic Water Heater Piping ...

Страница 50: ...50 RTAA IOM 3 Figure 30 Refrigerant Circuit Identification ...

Страница 52: ...52 RTAA IOM 3 Figure 31 Remote Evaporator Piping Example ...

Страница 58: ...58 RTAA IOM 3 Continued on Next Page Figure 34 Typical Field Wiring for RTAA Packaged Unit 130 to 200 Tons ...

Страница 59: ...59 RTAA IOM 3 Continued from Previous Page See Notes on Next Page ...

Страница 61: ...61 RTAA IOM 3 Figure 35 Typical Field Wiring for RTAA Packaged Unit 240 400 Tons Continued on Next Page ...

Страница 63: ...63 RTAA IOM 3 Continued from Previous Page See Notes on Page 61 ...

Страница 64: ...64 RTAA IOM 3 Figure 36 Typical Field Wiring for RTAA With Remote Evaporator Option Continued on Next Page ...

Страница 65: ...65 RTAA IOM 3 Continued from Previous Page See Notes on Page 61 ...

Страница 76: ...76 RTAA IOM 3 ...

Страница 78: ...78 RTAA IOM 3 Figure 40 Refrigeration System and Control Components Single Circuit Continued on Next Page ...

Страница 80: ...80 RTAA IOM 3 Figure 41 Refrigeration System and Control Components Duplex Circuit Continued on Next Page ...

Страница 92: ...92 RTAA IOM 3 Figure 51 Operator Interface Controls ...

Страница 120: ...120 RTAA IOM 3 ...

Страница 126: ...126 RTAA IOM 3 Figure 56 Unit Sequence of Operation RTAA 240 to 400 Tons Continued on Next Page ...

Страница 127: ...127 RTAA IOM 3 Continued from Previous Page 2307 1566C ...

Страница 128: ...128 RTAA IOM 3 Figure 57 Unit Sequence of Operation RTAA 130 to 200 Tons 2306 9122A ...

Страница 132: ...132 RTAA IOM 3 Figure 58 Operator s Log ...

Страница 138: ...138 RTAA IOM 3 ...