122

RTAA-IOM-3

[ ] Energize the evaporator and

Domestic Water Heater heat tape.

[ ] Fill the evaporator chilled water

circuit. Refer to Table 1 for

evaporator liquid capacities. Vent

the system while it is being filled.

Open the vent on the top of the

evaporator during filling and close

when filling is completed.

Customer Note

The use of improperly treated or

untreated water in this equipment may

result in scaling, erosion, corrosion,

algae or slime. The services of a

qualified water treatment specialist

should be engaged to determine what

treatment, if any, is advisable. The

Trane Company warranty specifically

excludes liability for corrosion, erosion

or deterioration of Trane equipment.

Trane assumes no responsibilities for

the results of the use of untreated or

improperly treated water, or saline or

brackish water.

Caution: Do not used untreated or

improperly treated water.

Equipment damage may occur.

Caution: Do not fill the water

systems unless the evaporator and

Domestic Water Heater heat tapes

have been energized.

[ ] Close the fused-disconnect

switch(es) that supplies power to

the chilled water pump starter.

[ ] Start the chilled water pump to

begin circulation of the chilled water.

Inspect all piping for leakage and

make any necessary repairs.

[ ] With chilled water circulating

through the system, adjust water

flow and check water pressure drop

through the evaporator. Refer to

Figure 23.

[ ] Adjust the chilled water flow switch

(if installed) for proper operation.

[ ] Prove Chilled Water Pump Interlock

and External Auto/Stop as described

in Interconnecting Wiring: Chilled

Water Pump Interlock and External

Auto/Stop.

Caution: Chilled Water Pump

Interlock and External Auto/Stop

information must be adhered to or

equipment damage may occur.

[ ] Check and set, as required, all UCM

Menu items.

[ ] Stop the chilled water pump.

Unit Voltage

Power Supply

Voltage to the unit must meet the

criteria given in Table 10. Measure each

leg of the supply voltage at the unit

main power fused-disconnect. If the

measured voltage on any leg is not

within specified range, notify the

supplier of the power and correct the

situation before operating the unit.

Caution: Inadequate voltage to the

unit can cause control components

to malfunction and shorten the life

of relay contact, compressor

motors and contactors.

Unit Voltage Imbalance

Excessive voltage imbalance between

the phases of a three-phase system can

cause Motors to overheat and

eventually fail. The maximum

allowable imbalance is 2 percent.

Voltage imbalance is determined using

the following calculations:

% Imbalance =

(Vx - Vave) x 100

Vave

Vave = (V1 + V2 + V3)

/ 3

Vx = phase with greatest difference

from Vave (without regard to sign)

For example, if the three measured

voltages are 221, 230, and 227 volts, the

average would be:

221 +230 +227 = 226

3

The percentage of imbalance is then:

100 (221 - 226) = 2.2%

226

This exceeds the maximum allowable

(2%) by 0.2 percent.

Содержание RTAA-130

Страница 2: ... American Standard Inc 1991 ...

Страница 8: ...8 RTAA IOM 3 ...

Страница 13: ...13 RTAA IOM 3 Figure 3 Typical RTAA Packaged Unit 240 400 Tons Control Panel Evaporator Outlet Inlet ...

Страница 24: ...24 RTAA IOM 3 ...

Страница 26: ...26 RTAA IOM 3 Figure 9 Dimensions and Clearances for RTAA Packaged Unit 130 to 200 Ton RTAA SU 1000E ...

Страница 27: ...27 RTAA IOM 3 Figure 10 Dimensions and Clearances for RTAA Packaged Unit 240 300 Ton RTAA SU 1001C ...

Страница 28: ...28 RTAA IOM 3 Figure 11 Dimensions and Clearances for RTAA Packaged Unit 340 to 400 Ton RTAA SU 1002C ...

Страница 38: ...38 RTAA IOM 3 RTAA SA 2002C Figure 19 Spring Isolator Placement for Typical RTAA Packaged Unit 240 400 Tons ...

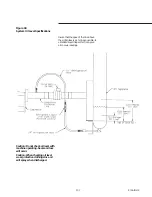

Страница 46: ...46 RTAA IOM 3 Figure 24 Typical Domestic Water Heater Piping Figure 25 Typical Domestic Water Heater Piping ...

Страница 50: ...50 RTAA IOM 3 Figure 30 Refrigerant Circuit Identification ...

Страница 52: ...52 RTAA IOM 3 Figure 31 Remote Evaporator Piping Example ...

Страница 58: ...58 RTAA IOM 3 Continued on Next Page Figure 34 Typical Field Wiring for RTAA Packaged Unit 130 to 200 Tons ...

Страница 59: ...59 RTAA IOM 3 Continued from Previous Page See Notes on Next Page ...

Страница 61: ...61 RTAA IOM 3 Figure 35 Typical Field Wiring for RTAA Packaged Unit 240 400 Tons Continued on Next Page ...

Страница 63: ...63 RTAA IOM 3 Continued from Previous Page See Notes on Page 61 ...

Страница 64: ...64 RTAA IOM 3 Figure 36 Typical Field Wiring for RTAA With Remote Evaporator Option Continued on Next Page ...

Страница 65: ...65 RTAA IOM 3 Continued from Previous Page See Notes on Page 61 ...

Страница 76: ...76 RTAA IOM 3 ...

Страница 78: ...78 RTAA IOM 3 Figure 40 Refrigeration System and Control Components Single Circuit Continued on Next Page ...

Страница 80: ...80 RTAA IOM 3 Figure 41 Refrigeration System and Control Components Duplex Circuit Continued on Next Page ...

Страница 92: ...92 RTAA IOM 3 Figure 51 Operator Interface Controls ...

Страница 120: ...120 RTAA IOM 3 ...

Страница 126: ...126 RTAA IOM 3 Figure 56 Unit Sequence of Operation RTAA 240 to 400 Tons Continued on Next Page ...

Страница 127: ...127 RTAA IOM 3 Continued from Previous Page 2307 1566C ...

Страница 128: ...128 RTAA IOM 3 Figure 57 Unit Sequence of Operation RTAA 130 to 200 Tons 2306 9122A ...

Страница 132: ...132 RTAA IOM 3 Figure 58 Operator s Log ...

Страница 138: ...138 RTAA IOM 3 ...