75

RTAA-IOM-3

Installation Check List

Complete this checklist as the unit is

installed, to verify that all

recommended procedures are

accomplished before the unit is started.

This checklist does not replace the

detailed Instructions given in the

“Installation -Mechanical” and

“Installation -Electrical” sections of this

manual. Read both sections

completely, to become familiar with the

installation procedures, prior to

beginning the work.

Receiving

[ ] Verify that the unit nameplate data

corresponds to the ordering

information.

[ ] Inspect the unit for shipping

damage and any shortages of

materials. Report any damage or

shortage to the carder.

Unit Location and Mounting

[ ] Inspect the location desired for

installation and verify adequate

service access clearances.

[ ] Provide drainage for evaporator

water.

[ ] Remove and discard all shipping

materials (cartons, etc.)

[ ] Install optional spring isolators, if

required.

[ ] Level the unit and secure it to the

mounting surface.

Unit Piping

[ ] Flush all unit water piping before

making final connections to the unit.

Caution: If using an acidic

commercial flushing solution,

construct a temporary bypass

around the unit to prevent damage

to internal components of the

evaporator.

Caution: To avoid possible

equipment damage, do not use

untreated or improperly treated

system water.

[ ] Connect the chilled water piping to

the evaporator.

[ ] Install pressure gauges and shutoff

valves on the chilled water inlet and

outlet to the evaporator.

[ ] Install a water strainer in the

entering chilled water line.

[ ] Install a balancing valve and flow

switch (discretionary) in the leaving

chilled water line.

[ ] Install a drain with shutoff valve or a

drain plug on the evaporator.

[ ] Vent the chilled water system at

high points in the system piping.

[ ] Apply heat tape and insulation, as

necessary, to protect all exposed

piping from freeze-up.

Electrical Wiring

WARNING: To prevent injury or

death, disconnect electrical

power source before completing

wiring connections to the unit.

Caution: To avoid corrosion and

overheating at terminal

connections, use copper

conductors only.

[ ] Connect the unit power supply

wiring with fused-disconnect to the

terminal block (or unit-mounted

disconnect) in the power section of

the control panel.

[ ] Connect the control power supply

wiring with fused-disconnect to the

terminal strip in the power section

of the control panel.

[ ] Connect power supply wiring to the

evaporator heat tape. Connect leads

551 and 552 to terminals 11 and 12

of terminal strip 1TB3.

[ ] Connect power supply wiring to the

chilled water pump.

[ ] Connect power supply wiring to any

auxiliary heat tapes.

[ ] Connect the auxiliary contact of the

chilled water pump (5K1) in series

with the optional flow switch, if

installed, and then connect to the

proper terminals.

[ ] For the External Start/Stop function,

install wiring from remote contacts

(5K5, 5K21) to the proper terminals

on terminal strip 1U1TB3.

Caution: Information in

Interconnecting Wiring: Chilled

Water Pump Interlock and External

Auto/Stop must be adhered to or

equipment damage may occur.

[ ] If the remote alarm/running/

maximum capacity contacts are

used, install leads 525 thru 532 from

the panel to the proper terminals on

terminal strip 1U1TB4.

[ ] If the emergency stop function is

used, install low voltage leads 513

and 514 to terminals 3 and 4 of

1U1TB1.

[ ] If indoor zone temperature is to be

used, install leads 501 and 502 on

6RT4 to the proper terminals on

1U2TB1.

[ ] If the ice making-option is used,

install leads 501 and 502 on 5K20 to

the proper terminals on 1U2TB1.

Содержание RTAA-130

Страница 2: ... American Standard Inc 1991 ...

Страница 8: ...8 RTAA IOM 3 ...

Страница 13: ...13 RTAA IOM 3 Figure 3 Typical RTAA Packaged Unit 240 400 Tons Control Panel Evaporator Outlet Inlet ...

Страница 24: ...24 RTAA IOM 3 ...

Страница 26: ...26 RTAA IOM 3 Figure 9 Dimensions and Clearances for RTAA Packaged Unit 130 to 200 Ton RTAA SU 1000E ...

Страница 27: ...27 RTAA IOM 3 Figure 10 Dimensions and Clearances for RTAA Packaged Unit 240 300 Ton RTAA SU 1001C ...

Страница 28: ...28 RTAA IOM 3 Figure 11 Dimensions and Clearances for RTAA Packaged Unit 340 to 400 Ton RTAA SU 1002C ...

Страница 38: ...38 RTAA IOM 3 RTAA SA 2002C Figure 19 Spring Isolator Placement for Typical RTAA Packaged Unit 240 400 Tons ...

Страница 46: ...46 RTAA IOM 3 Figure 24 Typical Domestic Water Heater Piping Figure 25 Typical Domestic Water Heater Piping ...

Страница 50: ...50 RTAA IOM 3 Figure 30 Refrigerant Circuit Identification ...

Страница 52: ...52 RTAA IOM 3 Figure 31 Remote Evaporator Piping Example ...

Страница 58: ...58 RTAA IOM 3 Continued on Next Page Figure 34 Typical Field Wiring for RTAA Packaged Unit 130 to 200 Tons ...

Страница 59: ...59 RTAA IOM 3 Continued from Previous Page See Notes on Next Page ...

Страница 61: ...61 RTAA IOM 3 Figure 35 Typical Field Wiring for RTAA Packaged Unit 240 400 Tons Continued on Next Page ...

Страница 63: ...63 RTAA IOM 3 Continued from Previous Page See Notes on Page 61 ...

Страница 64: ...64 RTAA IOM 3 Figure 36 Typical Field Wiring for RTAA With Remote Evaporator Option Continued on Next Page ...

Страница 65: ...65 RTAA IOM 3 Continued from Previous Page See Notes on Page 61 ...

Страница 76: ...76 RTAA IOM 3 ...

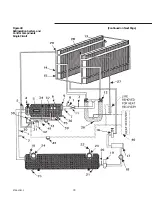

Страница 78: ...78 RTAA IOM 3 Figure 40 Refrigeration System and Control Components Single Circuit Continued on Next Page ...

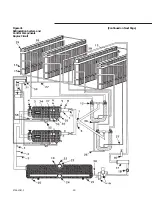

Страница 80: ...80 RTAA IOM 3 Figure 41 Refrigeration System and Control Components Duplex Circuit Continued on Next Page ...

Страница 92: ...92 RTAA IOM 3 Figure 51 Operator Interface Controls ...

Страница 120: ...120 RTAA IOM 3 ...

Страница 126: ...126 RTAA IOM 3 Figure 56 Unit Sequence of Operation RTAA 240 to 400 Tons Continued on Next Page ...

Страница 127: ...127 RTAA IOM 3 Continued from Previous Page 2307 1566C ...

Страница 128: ...128 RTAA IOM 3 Figure 57 Unit Sequence of Operation RTAA 130 to 200 Tons 2306 9122A ...

Страница 132: ...132 RTAA IOM 3 Figure 58 Operator s Log ...

Страница 138: ...138 RTAA IOM 3 ...