124

RTAA-IOM-3

1. Turn the Chiller Switch on the UCM

to the STOP/RESET position.

2. Open the electrical disconnect or

circuit protection switch that

provides line power to the line power

terminal block(s) in the starter panel

(or to the unit-mounted disconnect).

3. Connect the phase sequence

indicator leads to the line power

terminal block, as follows:

Phase Seq. Lead

Terminal

Black (Phase A) .................. L1

Red (Phase B) .................... L2

Yellow (Phase C) ................ L3

4. Turn power on by closing the unit

supply power fused- disconnect

switch.

5. Read the phase sequence on the

indicator. The “ABC” LED on the face

of the phase indicator will glow if

phase is “ABC”.

WARNING: To prevent injury or

death due to electrocution, take

extreme care when performing

service procedures with electrical

power energized.

6. If the “CBA” indicator glows instead,

open the unit main power disconnect

and switch two line leads on the line

power terminal block(s) (or the unit

mounted disconnect). Reclose the

main power disconnect and recheck

the phasing.

Caution: Do not interchange any

load leads that are from the unit

contactors or the motor terminals.

7. Reopen the unit disconnect and

disconnect the phase indicator.

Water System

Flow Rates

Establish a balanced chilled water flow

through the evaporator. The flow rates

should fall between the minimum and

maximum values given in Table 1.

Chilled water flow rates below the

minimum values will result in laminar

flow, which reduces heat transfer and

causes either loss of EXV control or

repeated nuisance, low temperature

cutouts. Flow rates that are too high

can cause tube erosion and damage to

the tube supports and baffles in the

evaporator.

Caution: Once the evaporator and

Domestic Water Heater (optional)

are filled with water, the heat tapes

must be energized to protect the

evaporator from freezing and

bursting if the outdoor air

temperature drops below freezing.

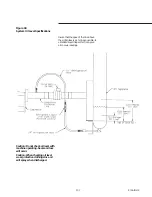

Water System

Pressure Drop

Measure chilled water pressure drop

through the evaporator at the field-

installed pressure taps on the system

water piping. See Figure 22. Use the

same gauge for each measurement. Do

not include valves, strainers fittings in

the pressure drop readings.

Measure the water pressure drop

through the Domestic Water Heater at

the field installed vent and drain

connections. See Figure 24. Use the

same gauge for each measurement. Do

not include valves, strainers, fittings in

pressure drop readings.

Pressure drop readings should be

approximately those shown in the

Pressure Drop Charts, Figure 23 for the

evaporator and Figure 25 for the

Domestic Water Heater (optional).

UCM Set-up

Refer to “Menu Function Descriptions

and Selection” for instruction on the

set-up of the UCM.

Содержание RTAA-130

Страница 2: ... American Standard Inc 1991 ...

Страница 8: ...8 RTAA IOM 3 ...

Страница 13: ...13 RTAA IOM 3 Figure 3 Typical RTAA Packaged Unit 240 400 Tons Control Panel Evaporator Outlet Inlet ...

Страница 24: ...24 RTAA IOM 3 ...

Страница 26: ...26 RTAA IOM 3 Figure 9 Dimensions and Clearances for RTAA Packaged Unit 130 to 200 Ton RTAA SU 1000E ...

Страница 27: ...27 RTAA IOM 3 Figure 10 Dimensions and Clearances for RTAA Packaged Unit 240 300 Ton RTAA SU 1001C ...

Страница 28: ...28 RTAA IOM 3 Figure 11 Dimensions and Clearances for RTAA Packaged Unit 340 to 400 Ton RTAA SU 1002C ...

Страница 38: ...38 RTAA IOM 3 RTAA SA 2002C Figure 19 Spring Isolator Placement for Typical RTAA Packaged Unit 240 400 Tons ...

Страница 46: ...46 RTAA IOM 3 Figure 24 Typical Domestic Water Heater Piping Figure 25 Typical Domestic Water Heater Piping ...

Страница 50: ...50 RTAA IOM 3 Figure 30 Refrigerant Circuit Identification ...

Страница 52: ...52 RTAA IOM 3 Figure 31 Remote Evaporator Piping Example ...

Страница 58: ...58 RTAA IOM 3 Continued on Next Page Figure 34 Typical Field Wiring for RTAA Packaged Unit 130 to 200 Tons ...

Страница 59: ...59 RTAA IOM 3 Continued from Previous Page See Notes on Next Page ...

Страница 61: ...61 RTAA IOM 3 Figure 35 Typical Field Wiring for RTAA Packaged Unit 240 400 Tons Continued on Next Page ...

Страница 63: ...63 RTAA IOM 3 Continued from Previous Page See Notes on Page 61 ...

Страница 64: ...64 RTAA IOM 3 Figure 36 Typical Field Wiring for RTAA With Remote Evaporator Option Continued on Next Page ...

Страница 65: ...65 RTAA IOM 3 Continued from Previous Page See Notes on Page 61 ...

Страница 76: ...76 RTAA IOM 3 ...

Страница 78: ...78 RTAA IOM 3 Figure 40 Refrigeration System and Control Components Single Circuit Continued on Next Page ...

Страница 80: ...80 RTAA IOM 3 Figure 41 Refrigeration System and Control Components Duplex Circuit Continued on Next Page ...

Страница 92: ...92 RTAA IOM 3 Figure 51 Operator Interface Controls ...

Страница 120: ...120 RTAA IOM 3 ...

Страница 126: ...126 RTAA IOM 3 Figure 56 Unit Sequence of Operation RTAA 240 to 400 Tons Continued on Next Page ...

Страница 127: ...127 RTAA IOM 3 Continued from Previous Page 2307 1566C ...

Страница 128: ...128 RTAA IOM 3 Figure 57 Unit Sequence of Operation RTAA 130 to 200 Tons 2306 9122A ...

Страница 132: ...132 RTAA IOM 3 Figure 58 Operator s Log ...

Страница 138: ...138 RTAA IOM 3 ...