42

RTAA-IOM-3

Evaporator Piping

Components

“Piping components” include all

devices and controls used to provide

proper water system operation and

unit operating safety. These

components and their general

locations are given below.

Entering Chilled Water Piping

[ ] Air vents (to bleed air from system).

[ ] Water pressure gauges with shutoff

valves.

[ ] Vibration eliminators.

[ ] Shutoff (isolation) valves.

Thermometers (if desired).

[ ] Clean-out tees.

[ ] Pipe strainer.

Caution: To prevent tube damage

install strainer in evaporator water

inlet piping.

Leaving Chilled Water Piping

[ ] Air vents (to bleed air from system).

[ ] Water pressure gauges with shutoff

valves. Vibration eliminators.

[ ] Shutoff (isolation) valves.

[ ] Thermometers.

[ ] Clean-out tees.

[ ] Balancing valve.

[ ] Flow Switch (If desired)

Caution: To prevent evaporator

damage, do not exceed 215 psig

(14.6 bar) evaporator water

pressure.

Evaporator Drain

A 3/4" drain connection is located

under the outlet end of the evaporator.

This may be connected to a suitable

drain to permit evaporator drainage

during unit servicing. A shutoff valve

must be installed on the drain line.

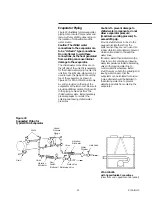

Evaporator Flow Switch

Chilled water flow protection is

provided by the UCM without the need

for a chilled water flow switch. A flow

switch for chilled water is strictly

discretionary but if not installed, a

signal still must be sent to the chiller to

indicate that water flow has been

established, e.g. chilled water pump

motor starter auxiliary contacts.

If additional chilled water flow

protection is desired, use a field-

installed flow switch or differential

pressure switch with the pump

interlock to sense system water flow.

Install and wire the flow switch in series

with the chilled water pump motor

starter auxiliaries (refer to “Electrical

Wiring”).

Specific connection and schematic

wiring diagrams are shipped with the

unit. Some piping and control

schemes, particularly those using a

single water pump for both chilled and

hot water, must be analyzed to

determine how and or if a flow sensing

device will provide desired operation.

Follow the manufacturer’s

recommendations for selection and

installation procedures. General

guidelines for flow switch installation

are outlined below

1. Mount the switch upright, with a

minimum of 5 pipe diameters of

straight horizontal run on each side.

Do not install close to elbows,

orifices or valves.

Note: The arrow on the switch must

point in the direction of flow.

2. To prevent switch fluttering, remove

all air from the water system.

Note: The UCM provides a 6-second

time delay after a “loss-of-flow”

diagnostic before shutting the unit

down. Contact a qualified service

representative if nuisance machine

shutdowns persist.

Содержание RTAA-130

Страница 2: ... American Standard Inc 1991 ...

Страница 8: ...8 RTAA IOM 3 ...

Страница 13: ...13 RTAA IOM 3 Figure 3 Typical RTAA Packaged Unit 240 400 Tons Control Panel Evaporator Outlet Inlet ...

Страница 24: ...24 RTAA IOM 3 ...

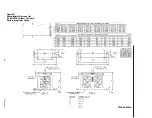

Страница 26: ...26 RTAA IOM 3 Figure 9 Dimensions and Clearances for RTAA Packaged Unit 130 to 200 Ton RTAA SU 1000E ...

Страница 27: ...27 RTAA IOM 3 Figure 10 Dimensions and Clearances for RTAA Packaged Unit 240 300 Ton RTAA SU 1001C ...

Страница 28: ...28 RTAA IOM 3 Figure 11 Dimensions and Clearances for RTAA Packaged Unit 340 to 400 Ton RTAA SU 1002C ...

Страница 38: ...38 RTAA IOM 3 RTAA SA 2002C Figure 19 Spring Isolator Placement for Typical RTAA Packaged Unit 240 400 Tons ...

Страница 46: ...46 RTAA IOM 3 Figure 24 Typical Domestic Water Heater Piping Figure 25 Typical Domestic Water Heater Piping ...

Страница 50: ...50 RTAA IOM 3 Figure 30 Refrigerant Circuit Identification ...

Страница 52: ...52 RTAA IOM 3 Figure 31 Remote Evaporator Piping Example ...

Страница 58: ...58 RTAA IOM 3 Continued on Next Page Figure 34 Typical Field Wiring for RTAA Packaged Unit 130 to 200 Tons ...

Страница 59: ...59 RTAA IOM 3 Continued from Previous Page See Notes on Next Page ...

Страница 61: ...61 RTAA IOM 3 Figure 35 Typical Field Wiring for RTAA Packaged Unit 240 400 Tons Continued on Next Page ...

Страница 63: ...63 RTAA IOM 3 Continued from Previous Page See Notes on Page 61 ...

Страница 64: ...64 RTAA IOM 3 Figure 36 Typical Field Wiring for RTAA With Remote Evaporator Option Continued on Next Page ...

Страница 65: ...65 RTAA IOM 3 Continued from Previous Page See Notes on Page 61 ...

Страница 76: ...76 RTAA IOM 3 ...

Страница 78: ...78 RTAA IOM 3 Figure 40 Refrigeration System and Control Components Single Circuit Continued on Next Page ...

Страница 80: ...80 RTAA IOM 3 Figure 41 Refrigeration System and Control Components Duplex Circuit Continued on Next Page ...

Страница 92: ...92 RTAA IOM 3 Figure 51 Operator Interface Controls ...

Страница 120: ...120 RTAA IOM 3 ...

Страница 126: ...126 RTAA IOM 3 Figure 56 Unit Sequence of Operation RTAA 240 to 400 Tons Continued on Next Page ...

Страница 127: ...127 RTAA IOM 3 Continued from Previous Page 2307 1566C ...

Страница 128: ...128 RTAA IOM 3 Figure 57 Unit Sequence of Operation RTAA 130 to 200 Tons 2306 9122A ...

Страница 132: ...132 RTAA IOM 3 Figure 58 Operator s Log ...

Страница 138: ...138 RTAA IOM 3 ...