129

RTAA-IOM-3

Unit Shutdown

Procedures

Temporary Shutdown

and Restart

To shut the unit down for a short time,

use the following procedure:

1. Move the Chiller Switch to STOP/

RESET. The compressors will

continue to operate and, after

unloading for 20 seconds, will stop

when the compressor contactors de-

energize. The condenser fans will be

de-energized at this time.

2. The unit disconnect switch and unit

mounted disconnect (if installed)

should remain closed to keep the

compressor sump heaters energized.

3. Maintain power to keep the

evaporator and Domestic Water

Heater heat tape(s) energized.

4. Stop the chilled water circulation by

turning off the chilled water pump.

To restart the unit after a temporary

shutdown, restart the chilled water

pump and move the Chiller Switch to

either of the AUTO positions. The unit

will start normally, provided the

following conditions exist:

1. The UCM must receive a call for

cooling and the differential- to-start

must be above the setpoint.

2. All system operating interlocks and

safety circuits must be satisfied.

Extended Shutdown

Procedure

The following procedure is to be

followed if the system is to be taken out

of service for an extended period of

time, e.g. seasonal shutdown:

1. Test the condenser and high-side

piping for refrigerant leakage.

2. Open the electrical disconnect

switches for the chilled water pump.

Lock the switch in the “OPEN”

position.

Caution: Lock the chilled water

pump disconnect open to prevent

pump damage.

3. Close all chilled water supply valves.

Drain the chilled water from the

evaporator. If the unit will be

exposed to freezing ambient

conditions, flush the evaporator with

an antifreeze solution and energize

the evaporator heat tape.

Caution: To prevent damage to the

evaporator by freezing, flush the

evaporator with an antifreeze

solution and energize the

evaporator heat tape.

4. Drain the Domestic Water Heater and

any exposed system piping to

prevent the possibility of freeze-up.

Use the pressure tap on the water

outlet to force compressed air

through the water coils of the unit

and assure that no water blocks any

of the tubes. Be certain that the drain

valve on the water inlet is open

before applying compressed air to

the water coils. Energize the

Domestic Water Heater heat tape.

Caution: To prevent damage to the

Domestic Water Heater by

freezing, blow out water from coils

and energize the Domestic Water

Heater heat tape.

5. Open the unit main electrical

disconnect and unit-mounted

disconnect (if installed) and lock on

the “OPEN” position. If optional

control power transformer is not

installed, open and lock the 115 V

disconnect.

Caution: Lock the disconnects on

the “OPEN” position to prevent

accidental start-up and damage to

the system when it has been setup

for extended shutdown.

6. At least every three months

(quarterly), check the pressure in the

unit to verify that the refrigerant

charge is intact.

Содержание RTAA-130

Страница 2: ... American Standard Inc 1991 ...

Страница 8: ...8 RTAA IOM 3 ...

Страница 13: ...13 RTAA IOM 3 Figure 3 Typical RTAA Packaged Unit 240 400 Tons Control Panel Evaporator Outlet Inlet ...

Страница 24: ...24 RTAA IOM 3 ...

Страница 26: ...26 RTAA IOM 3 Figure 9 Dimensions and Clearances for RTAA Packaged Unit 130 to 200 Ton RTAA SU 1000E ...

Страница 27: ...27 RTAA IOM 3 Figure 10 Dimensions and Clearances for RTAA Packaged Unit 240 300 Ton RTAA SU 1001C ...

Страница 28: ...28 RTAA IOM 3 Figure 11 Dimensions and Clearances for RTAA Packaged Unit 340 to 400 Ton RTAA SU 1002C ...

Страница 38: ...38 RTAA IOM 3 RTAA SA 2002C Figure 19 Spring Isolator Placement for Typical RTAA Packaged Unit 240 400 Tons ...

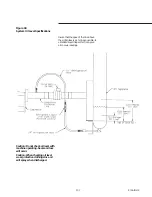

Страница 46: ...46 RTAA IOM 3 Figure 24 Typical Domestic Water Heater Piping Figure 25 Typical Domestic Water Heater Piping ...

Страница 50: ...50 RTAA IOM 3 Figure 30 Refrigerant Circuit Identification ...

Страница 52: ...52 RTAA IOM 3 Figure 31 Remote Evaporator Piping Example ...

Страница 58: ...58 RTAA IOM 3 Continued on Next Page Figure 34 Typical Field Wiring for RTAA Packaged Unit 130 to 200 Tons ...

Страница 59: ...59 RTAA IOM 3 Continued from Previous Page See Notes on Next Page ...

Страница 61: ...61 RTAA IOM 3 Figure 35 Typical Field Wiring for RTAA Packaged Unit 240 400 Tons Continued on Next Page ...

Страница 63: ...63 RTAA IOM 3 Continued from Previous Page See Notes on Page 61 ...

Страница 64: ...64 RTAA IOM 3 Figure 36 Typical Field Wiring for RTAA With Remote Evaporator Option Continued on Next Page ...

Страница 65: ...65 RTAA IOM 3 Continued from Previous Page See Notes on Page 61 ...

Страница 76: ...76 RTAA IOM 3 ...

Страница 78: ...78 RTAA IOM 3 Figure 40 Refrigeration System and Control Components Single Circuit Continued on Next Page ...

Страница 80: ...80 RTAA IOM 3 Figure 41 Refrigeration System and Control Components Duplex Circuit Continued on Next Page ...

Страница 92: ...92 RTAA IOM 3 Figure 51 Operator Interface Controls ...

Страница 120: ...120 RTAA IOM 3 ...

Страница 126: ...126 RTAA IOM 3 Figure 56 Unit Sequence of Operation RTAA 240 to 400 Tons Continued on Next Page ...

Страница 127: ...127 RTAA IOM 3 Continued from Previous Page 2307 1566C ...

Страница 128: ...128 RTAA IOM 3 Figure 57 Unit Sequence of Operation RTAA 130 to 200 Tons 2306 9122A ...

Страница 132: ...132 RTAA IOM 3 Figure 58 Operator s Log ...

Страница 138: ...138 RTAA IOM 3 ...