Error

Code

Diag.

Code

Device

Display

Meaning for the LMV5x System

Corrective Action

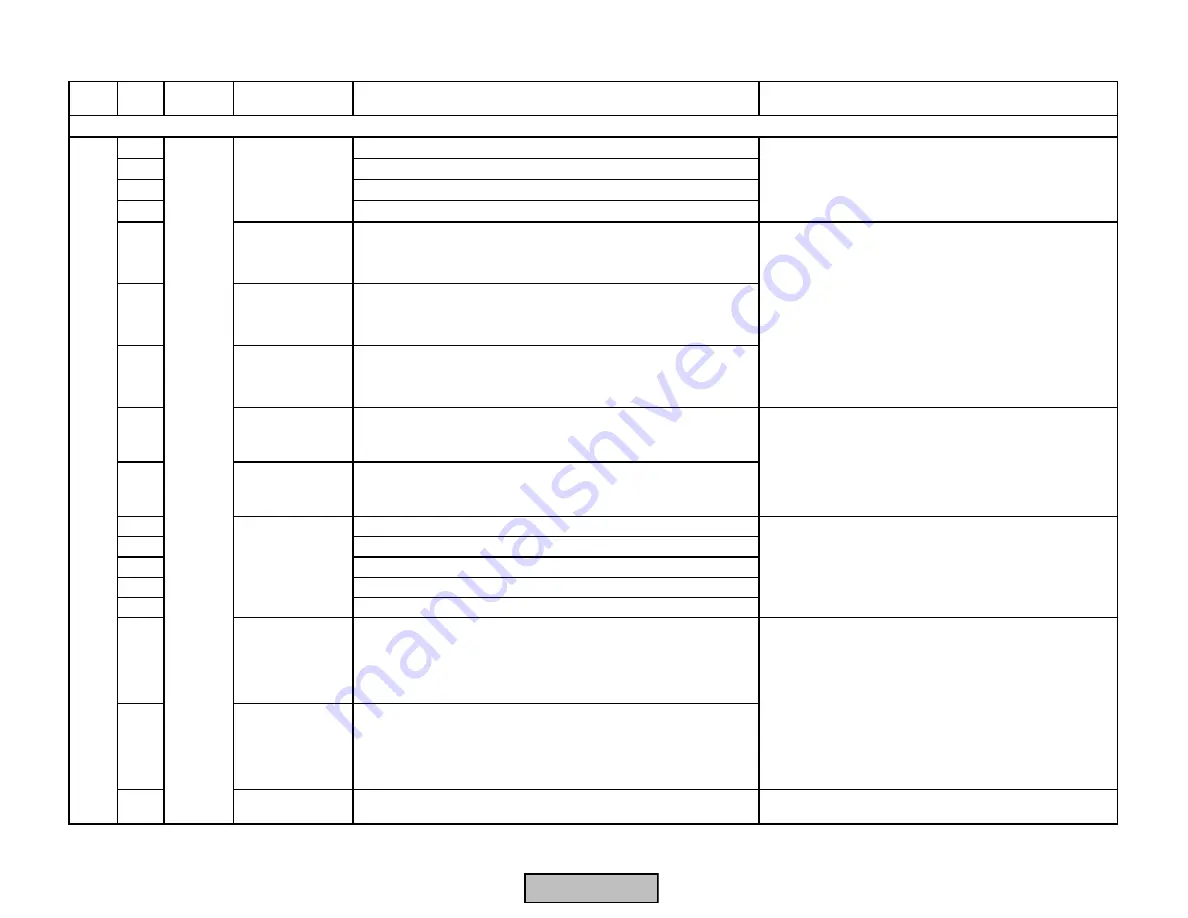

07

Sync fault or CRC fault

08

Error code for main loop counter

09

Fault during stack test

0A

Feedback values invalid

10

Unplaus Value

Nernst Voltage

O2 Module

Nernst voltage outside the valid range

12

Unplaus Value

Thermocouple O2

Module

Thermocouple voltage outside the valid range

13

Unplaus Value

Compensation

Element

Compensation element voltage outside the valid range

15

Unplaus Value

Flue Gas Temp

O2 Module

Temperature of combustion air sensor outside the valid range

(-20...+800 °C)

16

Unplaus Value

Flue Gas Temp

O2 Module

Temperature of flue gas sensor outside the valid range (-

20...+800 °C)

17

Fault during combustion air temperature sensor test

18

Fault during thermocouple test

19

Fault during compensation element test

1A

Fault during channel comparison of O2 signal

1B

Fault ADC test voltages

20

O2 Sensor Temp

too low

Temperature of QGO measuring cell too low

21

O2 Sensor Temp

too high

Temperature of QGO measuring cell too high

22

Internal Fault O2

Module

Fault during calculation test

If fault occurs constantly, replace O2 Sensor and / or

O2 Module

1) If fault occurs sporadically, reduce electrical noise.

2) If fault occurs continuously, replace PLL5..

Internal Fault O2

Module

1) Check the wiring between the O2 Module and the O2

sensor. Ensure high and low voltage are in seperate

conduits.

2) Check the power supply to the O2 Module

3) Check fuse in the O2 Module

4) Check the heating control on the O2 Sensor

5) Check the temperature inside the O2 Sensor terminal

box. Should be between -13 and 248

o

F

5) If fault occurs constantly, Replace O2 Sensor and /

or Module.

Fault with 02 Module (PLL5..) or Oxygen Sensor (QGO2..)

1) Check the wiring between the O2 Module and the O2

sensor.

2) Check the ambient / flue gas temperature. Compare

to valid range.

1) Check the wiring between the O2 Module and the O2

sensor.

2) If fault occurs constantly, replace O2 Sensor and / or

O2 Module

Internal Fault O2

Module

1) Check the temperature of heated sensor via

parameter

QGO SensorTemp.

Minimum operating

termperature is 1202

°

F, maximum 1382

°

F. O2 sensor

could take up to 20 minutes to reach temperature.

2) Ensure O2 sensor is installed properly (see mounting

section) and that stack gas velocity is correct. Min = 3.2

ft / sec, max = 32 ft / sec.

3) Check the power supply to the O2 Module

4) Check fuse in the O2 Module

PLL5..

AB

Section 7

Page 53

SCC Inc.

HOME

HOME

Содержание LMV 5 Series

Страница 2: ...Intentionally Left Blank ...

Страница 25: ...LMV Series Technical Instructions Document No LV5 1000 SCC Inc Page 21 Section 1 Intentionally Left Blank HOME ...

Страница 27: ...LMV Series Technical Instructions Document No LV5 1000 SCC Inc Page 23 Section 1 Intentionally Left Blank HOME ...

Страница 41: ...LMV Series Technical Instructions Document No LV5 1000 SCC Inc Page 7 Section 2 HOME ...

Страница 42: ...Technical Instructions LMV Series Document No LV5 1000 Section 2 Page 8 SCC Inc HOME ...

Страница 43: ...LMV Series Technical Instructions Document No LV5 1000 SCC Inc Page 9 Section 2 HOME ...

Страница 44: ...Technical Instructions LMV Series Document No LV5 1000 Section 2 Page 10 SCC Inc HOME ...

Страница 45: ...LMV Series Technical Instructions Document No LV5 1000 SCC Inc Page 11 Section 2 HOME ...

Страница 46: ...Technical Instructions LMV Series Document No LV5 1000 Section 2 Page 12 SCC Inc HOME ...

Страница 47: ...LMV Series Technical Instructions Document No LV5 1000 SCC Inc Page 13 Section 2 HOME ...

Страница 48: ...Technical Instructions LMV Series Document No LV5 1000 Section 2 Page 14 SCC Inc HOME ...

Страница 49: ...LMV Series Technical Instructions Document No LV5 1000 SCC Inc Page 15 Section 2 HOME ...

Страница 50: ...Technical Instructions LMV Series Document No LV5 1000 Section 2 Page 16 SCC Inc HOME ...

Страница 51: ...LMV Series Technical Instructions Document No LV5 1000 SCC Inc Page 17 Section 2 HOME ...

Страница 52: ...Technical Instructions LMV Series Document No LV5 1000 Section 2 Page 18 SCC Inc HOME ...

Страница 53: ...LMV Series Technical Instructions Document No LV5 1000 SCC Inc Page 19 Section 2 HOME ...

Страница 54: ...Technical Instructions LMV Series Document No LV5 1000 Section 2 Page 20 SCC Inc HOME ...

Страница 55: ...LMV Series Technical Instructions Document No LV5 1000 SCC Inc Page 21 Section 2 HOME ...

Страница 56: ...Technical Instructions LMV Series Document No LV5 1000 Section 2 Page 22 SCC Inc Intentionally Left Blank HOME ...

Страница 116: ...Technical Instructions LMV Series Document No LV5 1000 Section 3 Page 58 SCC Inc Intentionally Left Blank HOME ...

Страница 150: ...Technical Instructions LMV Series Document No LV5 1000 Section 4 Page 32 SCC Inc Intentionally Left Blank HOME ...

Страница 170: ...Technical Instructions LMV Series Document No LV5 1000 Section 5 Page 18 SCC Inc Intentionally Left Blank HOME ...

Страница 290: ...Technical Instructions LMV Series Document No LV5 1000 Section 8 Page 20 SCC Inc Intentionally Left Blank HOME ...

Страница 306: ...Technical Instructions LMV Series Document No LV5 1000 Section 9 Page 14 SCC Inc Intentionally Left Blank HOME ...

Страница 373: ...Intentionally Left Blank ...