Error

Code

Diag.

Code

Device

Display

Meaning for the LMV5x System

Corrective Action

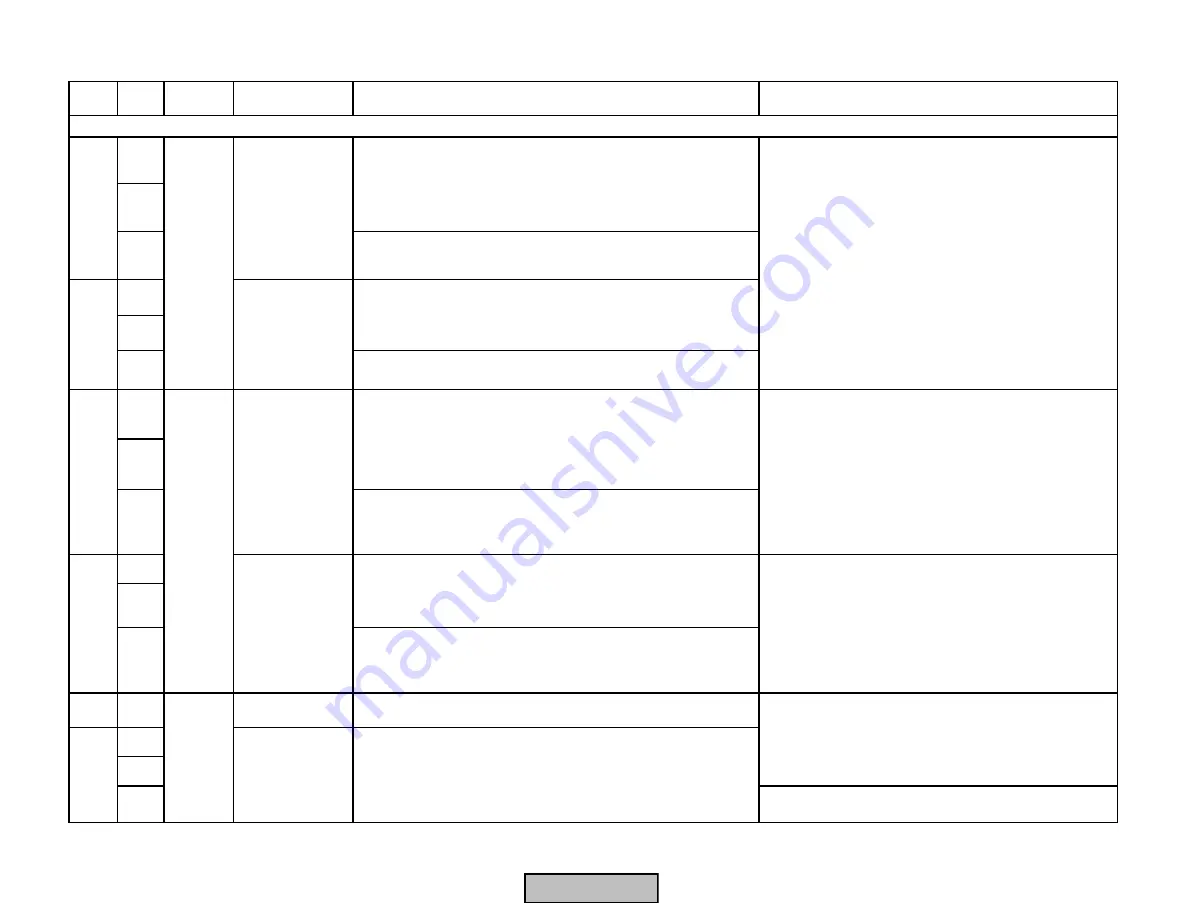

Any #

00

01I

03

Basic unit has detected extraneous light during startup

01 = QRI / QRB, 02 = ION / UV, 03 = any (LMV52 only)

Any #

00

01I

03

Basic unit has detected extraneous light during shutdown

01 = QRI / QRB, 02 = ION / UV, 03 = any (LMV52 only)

Any #

00

01I

03

No flame detected at the end of safety time TSA1 or TSA2

01 = QRI / QRB, 02 = ION / UV, 03 = any (LMV52 only)

Any #

00

01I

03

(LMV52 only) Loss of flame during normal operation

01 = QRI / QRB, 02 = ION / UV, 03 = any (LMV52 only)

27

Any #

Air Pressure on Air pressure = on, but should have been off

Any #

00

01

The error message may be traced back to an open

safety loop / burner flange.

1) Make sure blower starts in phase 22 and shuts off in

phase 78 or 83 (see sequence diagrams).

2) Check the setpoint on the air pressure switch. Raise

setpoint if necessary. Switch should open after

postpurge.

No flame detected at the end of safety time TSA1 or TSA2.

Loss of flame during normal operation (phase 60-62)

Air pressure = off, but should have been on

1) Check flame detector for signal in the presence of

flame using a flame source. Replace if detector does

not generate the anticipated signal.

2) Check for flame signal "decay" as burner refractory

heats up. If this happens, a UV scanner may be

needed.

3) Increase setting of

ReacTmeLossFlame

.

Basic unit has detected extraneous light during shutdown

1) Ensure that the source of extraneous light is not a

flame. If it is a flame, take corrective action

immediately.

2) If the QRI scanner is used, ambient light can cause

an extraneous light error. Ensure sensor is viewing a

dark area such as the inside of a boiler.

3) If the QRI scanner is used, check for glowing

refractory. If glowing refractor is the cause, the

afterburn time may need to be lengthened or a UV

scanner may have to be used.

Basic unit has detected extraneous light during startup

1) With a piloted gas train, this means that the pliot did

not light. Check wiring of ignition transformer and pilot

valve.

2) Check manual shutoff valves for the pilot gas.

3) Check position of air damper. Close further if

necessary. Pilot may be blowing out.

4) Check flame detector for signal in the presence of

flame using a flame source. Replace if detector does

not generate the anticipated signal.

LMV5 /

Flame

Detect.

Loss of Flame

Extraneous Light

on Shutdown

No Flame at End

of Safety Time

Fault with devices or wiring connected to the Base Unit (LMV5)

28

Air Pressure off

Devices

conn. to

LMV5

Extraneous Light

on Startup

25

26

23

24

LMV5 /

Flame

Detect.

Section 7

Page 31

SCC Inc.

HOME

HOME

Содержание LMV 5 Series

Страница 2: ...Intentionally Left Blank ...

Страница 25: ...LMV Series Technical Instructions Document No LV5 1000 SCC Inc Page 21 Section 1 Intentionally Left Blank HOME ...

Страница 27: ...LMV Series Technical Instructions Document No LV5 1000 SCC Inc Page 23 Section 1 Intentionally Left Blank HOME ...

Страница 41: ...LMV Series Technical Instructions Document No LV5 1000 SCC Inc Page 7 Section 2 HOME ...

Страница 42: ...Technical Instructions LMV Series Document No LV5 1000 Section 2 Page 8 SCC Inc HOME ...

Страница 43: ...LMV Series Technical Instructions Document No LV5 1000 SCC Inc Page 9 Section 2 HOME ...

Страница 44: ...Technical Instructions LMV Series Document No LV5 1000 Section 2 Page 10 SCC Inc HOME ...

Страница 45: ...LMV Series Technical Instructions Document No LV5 1000 SCC Inc Page 11 Section 2 HOME ...

Страница 46: ...Technical Instructions LMV Series Document No LV5 1000 Section 2 Page 12 SCC Inc HOME ...

Страница 47: ...LMV Series Technical Instructions Document No LV5 1000 SCC Inc Page 13 Section 2 HOME ...

Страница 48: ...Technical Instructions LMV Series Document No LV5 1000 Section 2 Page 14 SCC Inc HOME ...

Страница 49: ...LMV Series Technical Instructions Document No LV5 1000 SCC Inc Page 15 Section 2 HOME ...

Страница 50: ...Technical Instructions LMV Series Document No LV5 1000 Section 2 Page 16 SCC Inc HOME ...

Страница 51: ...LMV Series Technical Instructions Document No LV5 1000 SCC Inc Page 17 Section 2 HOME ...

Страница 52: ...Technical Instructions LMV Series Document No LV5 1000 Section 2 Page 18 SCC Inc HOME ...

Страница 53: ...LMV Series Technical Instructions Document No LV5 1000 SCC Inc Page 19 Section 2 HOME ...

Страница 54: ...Technical Instructions LMV Series Document No LV5 1000 Section 2 Page 20 SCC Inc HOME ...

Страница 55: ...LMV Series Technical Instructions Document No LV5 1000 SCC Inc Page 21 Section 2 HOME ...

Страница 56: ...Technical Instructions LMV Series Document No LV5 1000 Section 2 Page 22 SCC Inc Intentionally Left Blank HOME ...

Страница 116: ...Technical Instructions LMV Series Document No LV5 1000 Section 3 Page 58 SCC Inc Intentionally Left Blank HOME ...

Страница 150: ...Technical Instructions LMV Series Document No LV5 1000 Section 4 Page 32 SCC Inc Intentionally Left Blank HOME ...

Страница 170: ...Technical Instructions LMV Series Document No LV5 1000 Section 5 Page 18 SCC Inc Intentionally Left Blank HOME ...

Страница 290: ...Technical Instructions LMV Series Document No LV5 1000 Section 8 Page 20 SCC Inc Intentionally Left Blank HOME ...

Страница 306: ...Technical Instructions LMV Series Document No LV5 1000 Section 9 Page 14 SCC Inc Intentionally Left Blank HOME ...

Страница 373: ...Intentionally Left Blank ...