1-47

Various Settings

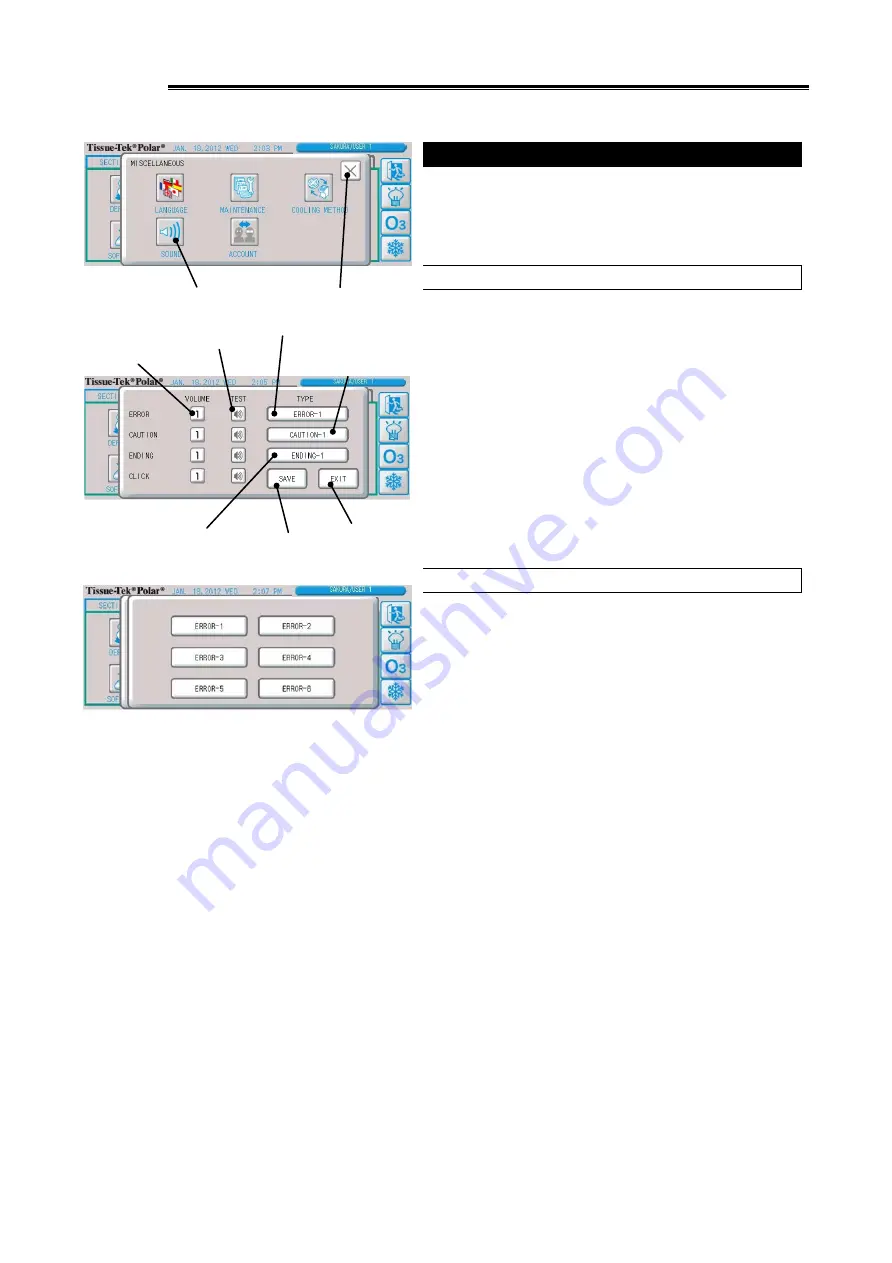

Setting Sounds

You can set the error sound, alarm sound, end sound and click

sound.

Changing the Sound Volume

1. Press the "Miscellaneous" button on the [UTILITIES] Tab

Screen.

2. Press the "Sound Setting" button on the other settings

screen.

3. The sound setting screen appears.

Pressing the "Sound Volume" button for the sound you want to

change the volume of, to increase the value and raise the sound

volume. The setting range is 1 to 8, and once 8 is reached, the

next pressing of the button returns the setting to 1.

You can test the selected sound by pressing the "Test" button.

4. Pressing the "Save" button saves the setting and closes the

setting screen.

Changing the Sound

1. Press the "Miscellaneous" button on the [UTILITIES] Tab

Screen.

2. Press the "Sound Setting" button on the other settings

screen.

3. The sound setting screen appears.

Press the button of the type of sound you want to change ("error

sound," "alarm sound" or "end sound"), and the sound selection

screen will appear.

4. Press the button of the sound you want to change, and the

display will return to the sound setting screen.

5. Pressing the "Save" button saves the setting and closes the

setting screen.

End sound button

Save button

Exit button

Sound volume

button

Alarm sound button

Test button

Error sound button

Close button

Sound setting button

Содержание Tissue-Tek Polar DM

Страница 1: ...Operating Manual Frozen Tissue Section Preparation Instrument Cryostat Microtome...

Страница 15: ...Chapter 1 Basic Knowledge of Instrument...

Страница 32: ...1 17 Standard Accessories Options 4 5 15...

Страница 68: ...1 53...

Страница 69: ...Chapter 2 Operating Method...

Страница 108: ...2 39...

Страница 109: ...Chapter 3 Maintenance Inspection...

Страница 122: ...3 13...

Страница 123: ...Chapter 4 Troubleshooting...