Pratt & Whitney Rzeszów S.A.

MAINTENANCE MANUAL

PZL-10W ENGINE

72-22-00

1992.08.28

Page 2

Export Control Classification: PL/UE 9E999

3.

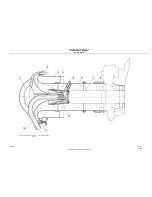

Operation (see Dwqs 1 and 2).

The contaminations contained in the air stream sucked to the engine are rejected to the surface of the dust

separator head (1) due to the forces of inertia and together with the air stream flow in the shell part of the

separator (4), from where due to ejection created by the air flowing out the nozzle (9) are sucked in and thrown

out via the pipe draining the contaminations (12) to the atmosphere. The cleaned air is sucked to the compressor

through the ring inlet duct created by the oil tank (3) with dust separator, inlet duct (6) and starter shield (7).

The engine with the dust separator installed may operate in the icing conditions because the dust separator head

(1 ) is heated by the hot oil scavenged from the engine and separator (4) is heated by the air delivered from the

combustion chamber case and by the air heating the starter shield (7).