d-Color MF4003/MF3303

P THEORY OF OPERATION > 1.

d-Color MF4003/MF3303

P-46

[3]

Fusing lever

[4]

Fusing pad

[5]

Fusing heater lamp (HL1)

[6]

Heating roller

[7]

Heating roller thermostat (TS1)

[8]

Pressure roller temperature sensor (TWMS)

[9]

Pressure roller thermistor/Ctr (TH2)

[10]

Pressure roller thermistor/Edg (TH1)

[11]

Fusing motor (M3)

-

1.13.2 Drive

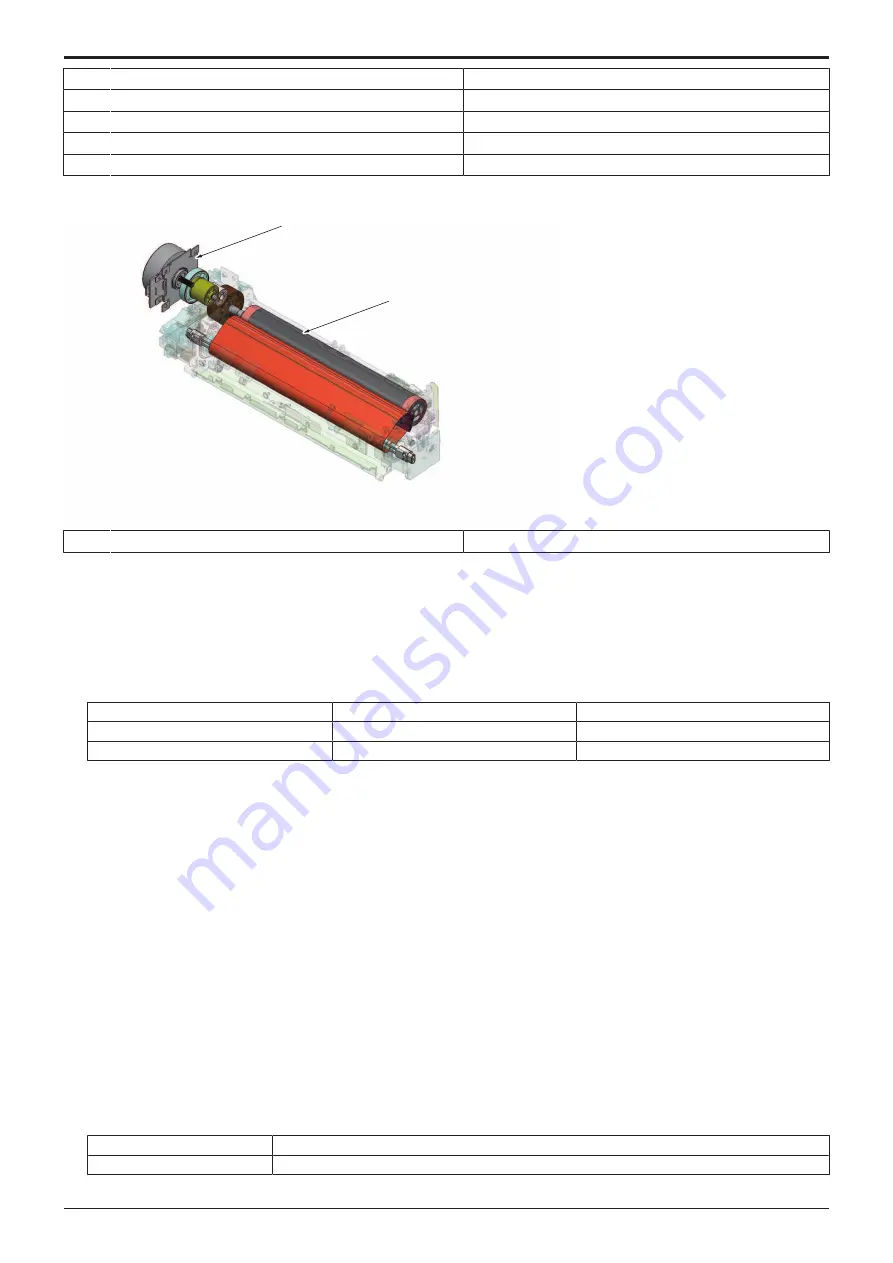

[1]

[2]

[1]

Fusing motor (M3)

[2]

Pressure roller

1.13.3 Operation

(1) Fusing speed correction

(a) Fusing loop control

• To prevent double transferred images and brush effects that occur due to a difference in speed between paper transport during image

transfer and fusing, a loop is formed in the paper between the 2nd transfer and fusing sections.

• The fusing loop sensor detects the length of the loop formed in the paper between the 2nd transfer section and the fusing roller.

• The fusing motor increases or decreases the fusing speed according to the length of loop in the paper, thereby ensuring that the length

of loop falls within a predetermined range.

Fusing loop sensor

Loop amount

Fusing speed

Blocking

Large

Speed-up

Unblocking

Small

Slowdown

Operation timing

• It starts controlling when the front-edge of the paper reaches to the predetermined position before the fusing roller.

• The fusing speed is decelerated so that a loop is formed in the paper between the 2nd transfer roller and the fusing roller.

• When the paper loop amount is large, the fusing loop sensor is unblocked, and the fusing speed is increased.

• When the paper loop amount is small, the fusing loop sensor is blocked, and the fusing speed is decreased.

• The fusing speed is increased or decreased as necessary to make sure that the paper loop amount falls within a predetermined range,

thereby absorbing a difference between the fusing speed and image transfer speed.

• The fusing loop control will finish after the trailing of the paper passes the 2nd transfer roller.

Fusing speed adjustment

• If double transferred images or brush effects occur due to inadequate paper loop before fusing, adjust the fusing speed using [Service

Mode] -> [Machine] -> [Fusing Transport Speed].

(2) Fusing belt deformation prevention control

• The fusing belt is rotated to prevent the fusing belt from remaining placed on the same side for long periods of time, preventing

deformation.

• Prevents uneven gloss due to fusing belt deformation.

(a) Specific controls

• Select Mode 2 in the Service Mode settings to enable the fusing belt deformation prevention control.

• Configured from [Service Mode] -> [System 2] -> [Fuser roll deform].

Mode

Specific controls

OFF

No control

Service Manual

Y119930-3

Содержание d-Color MF 4003

Страница 1: ...Multifunction Digital Copier d Color MF4003 MF3303 Service Manual Version 2 0 Code Y119930 3 ...

Страница 48: ...This page is intentionally left blank ...

Страница 54: ...This page is intentionally left blank ...

Страница 70: ...This page is intentionally left blank ...

Страница 76: ...This page is intentionally left blank ...

Страница 98: ...This page is intentionally left blank ...

Страница 216: ...This page is intentionally left blank ...

Страница 354: ...This page is intentionally left blank ...

Страница 388: ...This page is intentionally left blank ...

Страница 398: ...This page is intentionally left blank ...

Страница 512: ...d Color MF4003 MF3303 L TROUBLESHOOTING 10 DIAGNOSTIC CODES L 114 Not used bit is set to 0 Service Manual Y119930 3 ...

Страница 570: ...This page is intentionally left blank ...

Страница 572: ...This page is intentionally left blank ...

Страница 574: ...This page is intentionally left blank ...

Страница 686: ...This page is intentionally left blank ...

Страница 687: ...UPDATINGSTATUS DATE UPDATED PAGES PAGES CODE 2nd EDITION 688 Y119930 3 07 2019 1st EDITION 650 06 2020 ...