C70 Setup Manual

Appendix 2.16 Troubleshooting

575

Alarm No.

53

Excessive error 2

A difference between the actual and theoretical motor positions during servo OFF exceeded the setting value.

Investigation details

Investigation results

Remedies

SV

SP

1

Check the follow-up function while the NC is

in the servo OFF state.

The axis detachment function (NC

parameter) is invalid.

(Note) For the axis detachment function,

refer to the NC manual.

Check the investigation item No. 2.

The axis detachment function (NC

parameter) is valid.

(Note) For the axis detachment function,

refer to the NC manual.

Check the investigation item No. 3.

2

Check whether the axis has moved during

servo OFF (either by visual inspection or

monitor the position droop waveform).

[1] Check if the motor brake is released in

the middle.

[2] Check if the axis moves because the

servo OFF is applied during the C axis

mode.

[1] The axis has moved.

[2] The servo OFF is applied during the

mode.

[1] Adjust the brakes, etc. so that the axis

does not move.

[2] Avoid the servo OFF from being applied

during position control.

The axis has not moved.

Check the investigation item No. 3.

3

Check the excessive error detection width.

SV026 (Servo)

(Note) Set the same value to SV023.

The excessive error detection width is too

small.

SV026 ={RAPID/(60*PGN1)}/2

Set an appropriate value.

An appropriate value is set.

Check for problems on the NC side, such as

the position FB follow-up control.

Alarm No.

54

Excessive error 3

When an excessive error 1 occurred, detection of the motor current failed.

Investigation details

Investigation results

Remedies

SV

SP

1

Check that the PN voltage is supplied to the

drive unit.

[1] Is the CHARGE lamp ON?

The voltage is not supplied.

Correctly supply the PN voltage.

It is correctly supplied (DC300V).

Investigate item 2.

2

Check the motor power cable (U, V, W

phases).

[1] The power cable is not connected.

[2] Is the cable connected to the motor for

another axis?

The connections are incorrect.

Connect correctly.

The connections are correct.

Replace the drive unit.

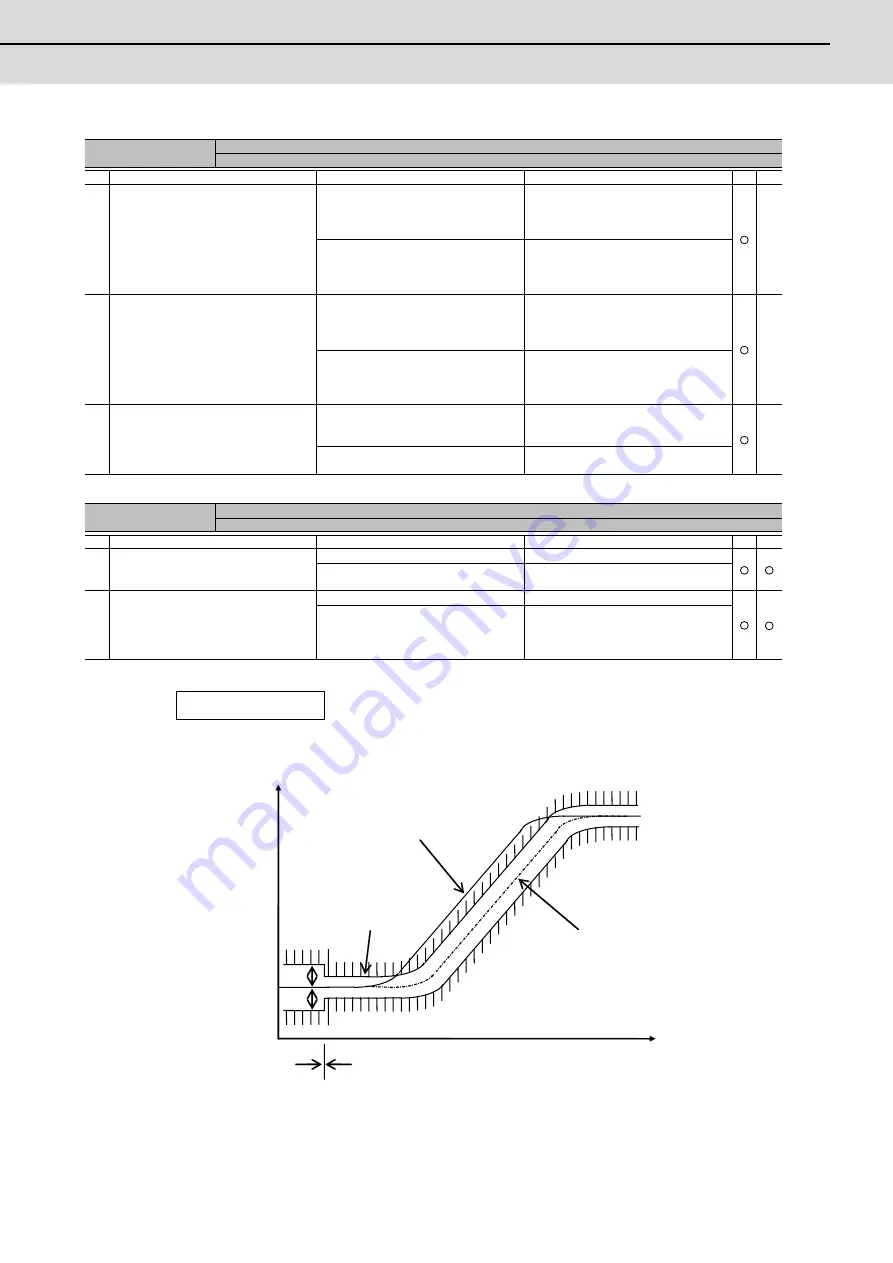

Servo OFF

Servo ON

Time

OD1

OD1

OD2

OD2

Position

Depending on the ideal machine position in respect to the command position, the actual machine

position could enter the actual shaded section shown below, which is separated more than the

distance set in OD1.

Supplement (servo)

Ideal machine position

Command position

Содержание C70

Страница 1: ......

Страница 3: ......

Страница 9: ......

Страница 11: ......

Страница 13: ......

Страница 18: ...1 1 Outline ...

Страница 21: ...1 Outline MITSUBISHI CNC 4 ...

Страница 22: ...5 2 GOT Initial Setup ...

Страница 73: ...2 GOT Initial Setup MITSUBISHI CNC 56 ...

Страница 74: ...57 3 PLC CPU Initial Setup ...

Страница 91: ...3 PLC CPU Initial Setup MITSUBISHI CNC 74 ...

Страница 92: ...75 4 CNC CPU Initial Setup ...

Страница 105: ...4 CNC CPU Initial Setup MITSUBISHI CNC 88 ...

Страница 106: ...89 5 Connecting and Setting up Multiple CNC CPU Modules ...

Страница 115: ...5 Connecting and Setting up Multiple CNC CPU Modules MITSUBISHI CNC 98 ...

Страница 116: ...99 6 Setting Machine Parameters ...

Страница 130: ...113 7 Setting the Position Detection System ...

Страница 153: ...7 Setting the Position Detection System MITSUBISHI CNC 136 ...

Страница 154: ...137 8 Deceleration Check ...

Страница 159: ...8 Deceleration Check MITSUBISHI CNC 142 ...

Страница 160: ...143 9 Setting the Tool Entry Prohibited Range ...

Страница 169: ...9 Setting the Tool Entry Prohibited Range MITSUBISHI CNC 152 ...

Страница 170: ...153 10 Data Backup and Restoration ...

Страница 184: ...167 Appendix 1 Explanation of Parameters ...

Страница 435: ...Appendix 1 Explanation of Parameters MITSUBISHI CNC 418 ...

Страница 436: ...419 Appendix 2 Explanation of Alarms ...

Страница 608: ...591 Appendix 3 Display on 7 segment LED ...

Страница 624: ......

Страница 628: ......