C70 Setup Manual

7.3 Adjustment in Absolute Position Detection System

135

7.3.4 Dog-type Absolute Position Zero Point Initialization Set

Execute the dog-type reference position return with the manual reference position return mode or automatic reference

position return command (G28).

Use GOT project controlled by sequence programs, switches on the machine operation panel, manual handle, and the

[ABS. POSITION SET] screen in the CNC monitor on GOT for the absolute position zero point initialization set. The GOT

project and panel switches are made by the machine tool builder.

(1)

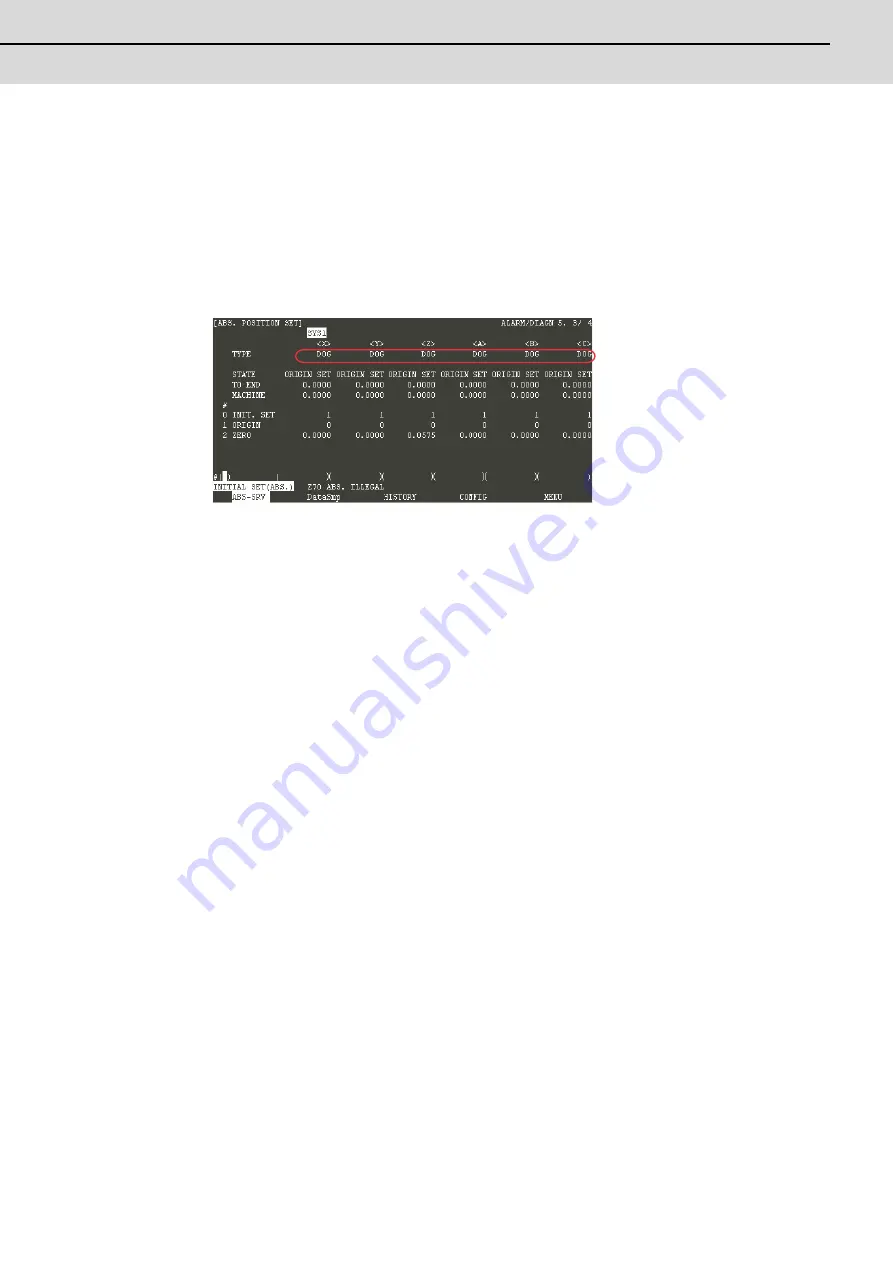

Select [ALARM/DIAGN] ---> [MENU (MENU 5)] ---> [ABS SERVO MONITOR] in the CNC monitor on GOT. Scroll

the page to display the [ABS. POSITION SET] screen.

Check that the "DOG" is applied for the axis for which the absolute position zero point is to be initialized.

(Note)

The type of absolute position zero point initialization set is decided by the machine and axes

specifications, although "DOG" can be selected by setting "3" for "#2049 type Absolute position detection

method". Confirm whether the machine specifications allow the "DOG" before changing the type.

(2)

Perform manual or automatic dog type reference point return.

(3)

The absolute position will be established under the completion of the reference position return. The basic machine

coordinate system will be automatically set.

(4)

Carry out the absolute position initialization set for all the axes, and then turn the power ON again.

(Note 1) If the dog type reference position return is stopped by resetting, the previous state (OK or NG) will be

displayed for "STATE".

(Note 2) The necessary data will be saved in EEROM upon the establishment of the absolute position. The message

notifies that the data is being written in EEROM.

(Note 3) With dog-type, the reference position return can be executed again even if the "STATE" displays "OK".

Содержание C70

Страница 1: ......

Страница 3: ......

Страница 9: ......

Страница 11: ......

Страница 13: ......

Страница 18: ...1 1 Outline ...

Страница 21: ...1 Outline MITSUBISHI CNC 4 ...

Страница 22: ...5 2 GOT Initial Setup ...

Страница 73: ...2 GOT Initial Setup MITSUBISHI CNC 56 ...

Страница 74: ...57 3 PLC CPU Initial Setup ...

Страница 91: ...3 PLC CPU Initial Setup MITSUBISHI CNC 74 ...

Страница 92: ...75 4 CNC CPU Initial Setup ...

Страница 105: ...4 CNC CPU Initial Setup MITSUBISHI CNC 88 ...

Страница 106: ...89 5 Connecting and Setting up Multiple CNC CPU Modules ...

Страница 115: ...5 Connecting and Setting up Multiple CNC CPU Modules MITSUBISHI CNC 98 ...

Страница 116: ...99 6 Setting Machine Parameters ...

Страница 130: ...113 7 Setting the Position Detection System ...

Страница 153: ...7 Setting the Position Detection System MITSUBISHI CNC 136 ...

Страница 154: ...137 8 Deceleration Check ...

Страница 159: ...8 Deceleration Check MITSUBISHI CNC 142 ...

Страница 160: ...143 9 Setting the Tool Entry Prohibited Range ...

Страница 169: ...9 Setting the Tool Entry Prohibited Range MITSUBISHI CNC 152 ...

Страница 170: ...153 10 Data Backup and Restoration ...

Страница 184: ...167 Appendix 1 Explanation of Parameters ...

Страница 435: ...Appendix 1 Explanation of Parameters MITSUBISHI CNC 418 ...

Страница 436: ...419 Appendix 2 Explanation of Alarms ...

Страница 608: ...591 Appendix 3 Display on 7 segment LED ...

Страница 624: ......

Страница 628: ......